We have five sugar maples growing near the house, and Rachel figured it would

be a fun activity to try to make some maple syrup. So Rachel and Harriet

tapped the trees and started collecting some sap.

We have five sugar maples growing near the house, and Rachel figured it would

be a fun activity to try to make some maple syrup. So Rachel and Harriet

tapped the trees and started collecting some sap.

We have five sugar maples growing near the house, and Rachel figured it would

be a fun activity to try to make some maple syrup. So Rachel and Harriet

tapped the trees and started collecting some sap.

We have five sugar maples growing near the house, and Rachel figured it would

be a fun activity to try to make some maple syrup. So Rachel and Harriet

tapped the trees and started collecting some sap.

Sugar maple sap, before the leaves start to bud, is about 2% sugar. To make maple syrup, the water component is boiled away until it's about 1/40th of its original volume.

We figured we could let it boil in a rice cooker outside. But the rice cooker is only 500 watts, so it was a very slow boil.

But then I had the idea of using a kettle, which uses 1800 watts, so it

boils much faster.

But then I had the idea of using a kettle, which uses 1800 watts, so it

boils much faster.

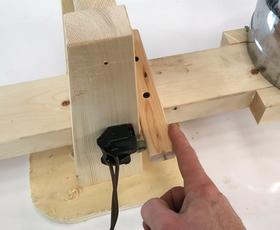

This kettle doesn't have an automatic shut off, so I can leave it boiling, but it's important to stop the boil before it runs dry. So I built this balance, which has a switch on it to cut power when the kettle gets too light.

I also wanted some means of automatically refilling the kettle when it got low for unattended overnight boils (when electricity is cheapest).

I needed a bucket with some sort of valve that opens when the kettle

gets lighter. This would have to open very easily so I couldn't use

a proper plumbing type valve.

I needed a bucket with some sort of valve that opens when the kettle

gets lighter. This would have to open very easily so I couldn't use

a proper plumbing type valve.

My idea was to have a small hole in the bottom of the bucket, and something that presses against the hole to stop the flow, but releases the pressure when the kettle rises.

I made this crank/lever contraption using some stainless steel rod. I just needed some sort of rubber stopper to mount to the crank part.

But I couldn't find what I had in mind in the scraps I have, so instead I used

a thick piece of rubber from a truck mud flap, held in place with a piece

of copper wire. The crank presses it against the bucket.

But I couldn't find what I had in mind in the scraps I have, so instead I used

a thick piece of rubber from a truck mud flap, held in place with a piece

of copper wire. The crank presses it against the bucket.

Here you can see the water running from lifting the lever. But it couldn't quite stop the flow when the lever dropped. I added a weight, but even with tweaking it, there was still a slow drip. But a slow drip is OK, as long as the kettle can boil faster than the drip.

Testing the valve contraption with the kettle. I added a wooden arm to extend over

the kettle and lift the stainless steel rod when the kettle rises.

Testing the valve contraption with the kettle. I added a wooden arm to extend over

the kettle and lift the stainless steel rod when the kettle rises.

I also attached a 1/2" hex nut to the stainless steel rod to weigh it down and help press the valve closed. I let the spout fill the kettle to make sure the balance would tip kettle down, turn on the power switch, and close the valve.

With the valve fully opened, I found the water running down the spout I made overshot

the kettle. I also had some problems with surface tension causing the water to flow

off to the side on the bucket, even though I cut some notches in the bottom edge

to try to prevent that. This was very reminiscent of the

mysterious leaking dehumidifier.

With the valve fully opened, I found the water running down the spout I made overshot

the kettle. I also had some problems with surface tension causing the water to flow

off to the side on the bucket, even though I cut some notches in the bottom edge

to try to prevent that. This was very reminiscent of the

mysterious leaking dehumidifier.

But once the flow slowed to a drip, it worked OK. During a boil, the flow rate is very low, so it would be OK.

Releasing lots of steam in the workshop would be a bad idea, so I set it up outside on the

front porch where it was easy to keep an eye on. I had some problems getting

it all tweaked right, resulting in some spillage.

Releasing lots of steam in the workshop would be a bad idea, so I set it up outside on the

front porch where it was easy to keep an eye on. I had some problems getting

it all tweaked right, resulting in some spillage.

I also wrapped the kettle in tinfoil to cut down on heat loss through the walls of the kettle. I wanted as much of the heat to go towards boiling the sap as possible.

The maple sap foams up a bit, so I had to bend open the area around the spout to keep the foam from coming out. But after that boil, looking in kettle, I could see that there was quite a bit of soldering inside the kettle. Given the age of this kettle, it's highly likely that this was leaded solder. And considering how long the sap was boiling in there, that would make the sap contaminated. It would have cost more to test for lead than the value of the liter of maple syrup we produced so far, so we dumped it down the drain (what a shame!) and started over.

I switched back to the rice cooker. But it was a slow boil. Even wrapped

in tinfoil, I imagine over 100 of its 500 watts heater was needed just to

make up for heat loss and maintain a boiling temperature.

That would leave less than 400 watts to do the boiling.

It was boiling away less than half a liter per hour. This was so slow that

letting it boil all night (when the electricity is cheapest), it still

couldn't boil away the day's collected sap. It was so slow that the valve on

the bucket formed an icicle in cold temperatures and froze shut!

I switched back to the rice cooker. But it was a slow boil. Even wrapped

in tinfoil, I imagine over 100 of its 500 watts heater was needed just to

make up for heat loss and maintain a boiling temperature.

That would leave less than 400 watts to do the boiling.

It was boiling away less than half a liter per hour. This was so slow that

letting it boil all night (when the electricity is cheapest), it still

couldn't boil away the day's collected sap. It was so slow that the valve on

the bucket formed an icicle in cold temperatures and froze shut!

I used a thrift store wok to boil the sap to final concentration (the final

boil needs to be watched carefully). I put some lawn chairs around

it to protect it from the wind and wrapped some tinfoil around it

to help retain heat. The wok, at 1000 watts, boiled much faster

than the rice cooker.

I used a thrift store wok to boil the sap to final concentration (the final

boil needs to be watched carefully). I put some lawn chairs around

it to protect it from the wind and wrapped some tinfoil around it

to help retain heat. The wok, at 1000 watts, boiled much faster

than the rice cooker.

My next step was to adapt the wok to do the main boiling.

The wok was too large a diameter. Filling it to capacity resulted in

so much heat loss that it never came to a boil.

So I cut about 2 cm off the edge of it, then bent

the new edge down. I also modified the lid to make it more dome shaped so that

condensation on the lid would run down to the edges, then drip outside

the pot instead of into it. Condensation dripping into the pot would need to

get boiled again, and that would be a waste of heat.

My next step was to adapt the wok to do the main boiling.

The wok was too large a diameter. Filling it to capacity resulted in

so much heat loss that it never came to a boil.

So I cut about 2 cm off the edge of it, then bent

the new edge down. I also modified the lid to make it more dome shaped so that

condensation on the lid would run down to the edges, then drip outside

the pot instead of into it. Condensation dripping into the pot would need to

get boiled again, and that would be a waste of heat.

This worked well enough. Not as fast as the lead soldered kettle, but it could keep

up with our maple sap collection, boiling away about 1 liter per hour. I should buy a dedicated, lead free,

tall kettle for this. But by this time, the sap run was nearly done, so it

wasn't worth upgrading. Once the nights aren't below freezing anymore, the

sap stops running. And when the trees start to bud, the sap will taste very bad.

This worked well enough. Not as fast as the lead soldered kettle, but it could keep

up with our maple sap collection, boiling away about 1 liter per hour. I should buy a dedicated, lead free,

tall kettle for this. But by this time, the sap run was nearly done, so it

wasn't worth upgrading. Once the nights aren't below freezing anymore, the

sap stops running. And when the trees start to bud, the sap will taste very bad.

Emptying the wok after a full 12 hour overnight boil. I ran most of my boils overnight,

from 7 pm to 7 am, while the electricity was cheaper.

Emptying the wok after a full 12 hour overnight boil. I ran most of my boils overnight,

from 7 pm to 7 am, while the electricity was cheaper.

This particular bucket had more sugar content than I anticipated, so what was in the wok by the morning was very thick, but very tasty. I actually had to add water. If the sugar concentration is too high (above 66%), the syrup turns into big sugar crystals over time.