Yiyong Leng's homemade jointer

Matthias:

Matthias:

Hello again! :) I bought your plans a long time ago, until now, I have finished my homemade jointer building. Thank you for the genius of your design so that I have the courage to complete such a complex project step by step! Your plans are excellent both in drawings and 3D models.

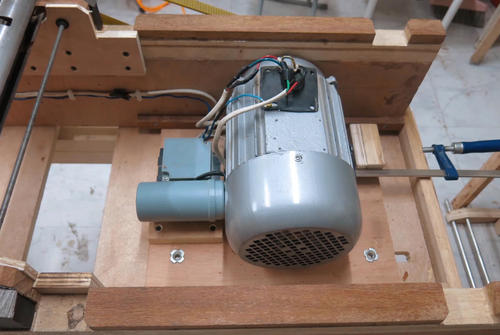

I took apart my previous thickness planer and reused the cutter head, bearing

seats, induction motor, pulleys, belt and switch from it.

I took apart my previous thickness planer and reused the cutter head, bearing

seats, induction motor, pulleys, belt and switch from it.

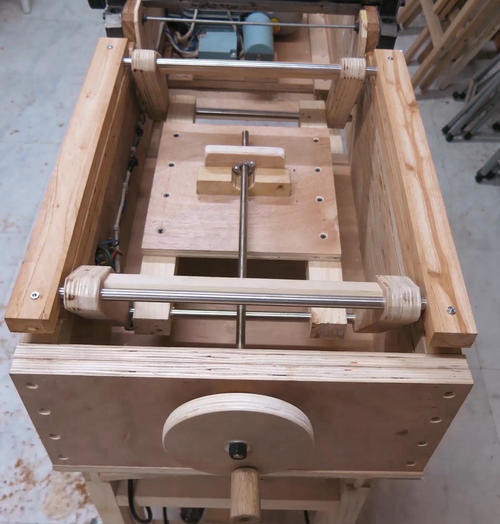

According to the shape of my bearing seat, I think of a best way to put it on

the jointer's frame. There is a block of wood be placed between two feet, so

the bearing seat can’t be moved right and left. And the foot has a M8 thread

hole on both side bottom, I screwed a short thread rod into there through the

wooden frame, then I locked it with a nut. There are two boards behind and up

against the bearing block, I think it's helpful to increase its stability.

According to the shape of my bearing seat, I think of a best way to put it on

the jointer's frame. There is a block of wood be placed between two feet, so

the bearing seat can’t be moved right and left. And the foot has a M8 thread

hole on both side bottom, I screwed a short thread rod into there through the

wooden frame, then I locked it with a nut. There are two boards behind and up

against the bearing block, I think it's helpful to increase its stability.

When I turn the shaft, I find it's not too smooth. I think this may be caused

by the two bearing seats are not parallel enough. I inserted two thread rods

for parallelism adjustment with nuts. There is a pair of nuts on each side,

one is used for adjustment, the other is for locking. So two thread rods have

four adjustable positions for Parallelism adjustment. and finally, it becomes

smooth.

When I turn the shaft, I find it's not too smooth. I think this may be caused

by the two bearing seats are not parallel enough. I inserted two thread rods

for parallelism adjustment with nuts. There is a pair of nuts on each side,

one is used for adjustment, the other is for locking. So two thread rods have

four adjustable positions for Parallelism adjustment. and finally, it becomes

smooth.

The reason why I didn't make wooden bearing seat is that I can't find available

high quality plywood at all in my city. The body of the jointer and the in/out

feed tables are made out of cheap plywood.

The reason why I didn't make wooden bearing seat is that I can't find available

high quality plywood at all in my city. The body of the jointer and the in/out

feed tables are made out of cheap plywood.

Frankly, I painted the jointer after finishing the assembly to hide the ugly materials actually. I think it does not affect the actual use of. It looks like a test of what a poor material can do.

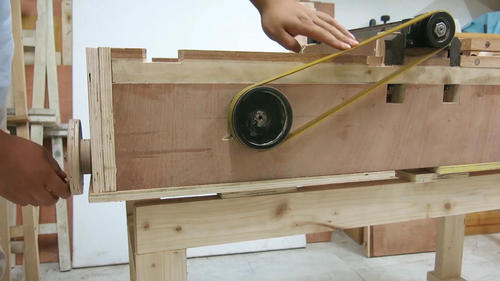

The way to tension belt is to move the induction motor horizontally, and then

lock the sled of motor by tightening the blot from the bottom.

The way to tension belt is to move the induction motor horizontally, and then

lock the sled of motor by tightening the blot from the bottom.

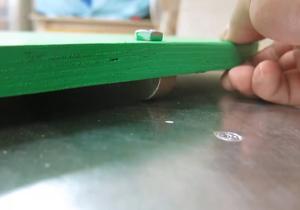

I added a half round nut be touched the table for reducing friction when

the guard returning.

I added a half round nut be touched the table for reducing friction when

the guard returning.

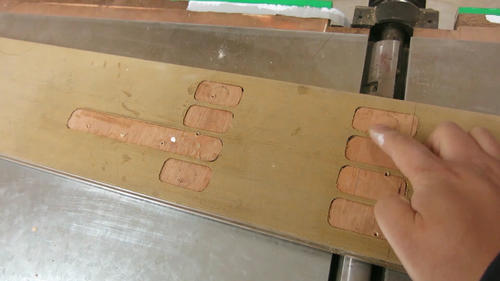

My fence was cutted from a hollow inside MDF floor( I picked it from a

dump by the roadside ), I put a few of plywood into the back of the floor

for better screwing.

My fence was cutted from a hollow inside MDF floor( I picked it from a

dump by the roadside ), I put a few of plywood into the back of the floor

for better screwing.

After jointing, the board is to be flat enough. And also the edge of the

lumber, I think it's no problem with edge jointing board.

After jointing, the board is to be flat enough. And also the edge of the

lumber, I think it's no problem with edge jointing board.

I have a vedio for showing the process of this jointer's making

I have a vedio for showing the process of this jointer's making

https://www.youtube.com/watch?v=7SAj4fdpOlc

Yiyong Leng

See also:

Yiyong Leng's tenon jig and other projects

Yiyong Leng's tenon jig and other projects Homemade jointer

Homemade jointer Carlos's jointer

Carlos's jointer