Hoffman dovetailing system

Getting the alignment on miter joints is tricky. I previously wrote about

a way to join miters,

but this

Hoffman dovetailing system, though not as strong, is much faster.

Getting the alignment on miter joints is tricky. I previously wrote about

a way to join miters,

but this

Hoffman dovetailing system, though not as strong, is much faster.

It consists of a machine to cut blind dovetails keyways into the miters of a frame, and these little plastic dovetails keys that are then driven into the dovetail keyways.

Although the little plastic dovetails hold the miter together surprisingly well, they aren't meant to be the only thing holding it together. Their main purpose is to hold the joint together and aligned while the glue dries. This eliminates any fiddling or marking up the wood with complicated miter clamps.

Hoffman sells various machines for joining the corners. Kurt's machine for doing this is not

one of the machines from Hoffman, but an unlabeled knockoff copy that does the same thing.

Mechanically, it works exactly like the low end Hoffman machines.

Hoffman sells various machines for joining the corners. Kurt's machine for doing this is not

one of the machines from Hoffman, but an unlabeled knockoff copy that does the same thing.

Mechanically, it works exactly like the low end Hoffman machines.

|

|

Operating the machine is very simple. The workpiece is slid into the machine, then

the router is turned on, and the lever pulled forward. Pulling the lever forward first

lowers the clamping block, securing the work piece in place, and then pulls the router

up into the wood.

Operating the machine is very simple. The workpiece is slid into the machine, then

the router is turned on, and the lever pulled forward. Pulling the lever forward first

lowers the clamping block, securing the work piece in place, and then pulls the router

up into the wood.

First one piece is inserted from one side, and a keyway cut. Then the other piece is slid in from the other side. The second piece essentially is a mirror image of the first piece.

The middle "home plate" shaped metal plate can be adjusted in and out along a track, which ensures that the whole setup is always symmetrical, so that proper alignment of the two dovetails in the mating pieces is ensured.

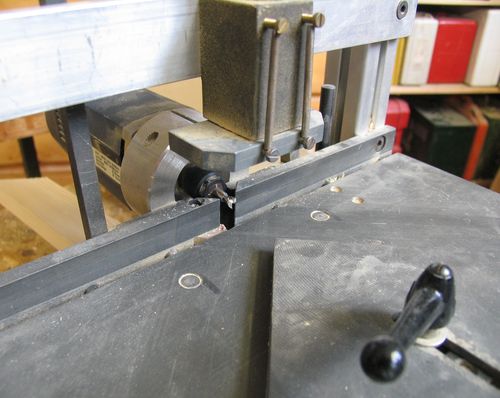

A close-up view of the cutter head. The cutter head normally only rises above the

level of the table while cuts are made. I jammed a piece of wood under the router

to take this photo, to show the cutter head up without a work piece obstructing it.

A close-up view of the cutter head. The cutter head normally only rises above the

level of the table while cuts are made. I jammed a piece of wood under the router

to take this photo, to show the cutter head up without a work piece obstructing it.

The little plastic dovetail wedges are tapped in with a hammer, either flush, or sunk

below the surface. Normally, glue is applied before the dovetail is driven in, though

the joint in this photo was just a test joint without any glue.

The little plastic dovetail wedges are tapped in with a hammer, either flush, or sunk

below the surface. Normally, glue is applied before the dovetail is driven in, though

the joint in this photo was just a test joint without any glue.

Unfortunately, use of such a gadget does require using the little Hoffman dovetail wedges.

These come in various length, colours, and sizes. But they do need to be bought from Hoffman,

and add a few cents per joint to the cost of a project.

Unfortunately, use of such a gadget does require using the little Hoffman dovetail wedges.

These come in various length, colours, and sizes. But they do need to be bought from Hoffman,

and add a few cents per joint to the cost of a project.

Perhaps once the patents on this system expire, and competitors flood the market, this system will become cheaper and more widespread.

d