Geared Pantorouter Upgrades

I made some upgrades to the Geared Pantorouter.

The original lift mechanism used a single block to hold the template plate. The 3/8" threaded

rod holding the block had too much flex and caused inaccuracies.

The original lift mechanism used a single block to hold the template plate. The 3/8" threaded

rod holding the block had too much flex and caused inaccuracies.

The new mechanism uses a 1/2 steel shaft with bronze bushings. The threaded rod is now only used for lifting, not to provide stability. I also split the block in two which allows for maximum distance between the mounting points. Over all this greatly improved stiffness and the lifting action works even smoother than before.

Since I was at it I also decided to replace my wooden ruler with a digital readout.

This DRO makes setup a lot more convenient and accurate. When the Pantorouter is used as a

slot mortiser, the DRO makes cutting multiple mortise joints a breeze.

Since I was at it I also decided to replace my wooden ruler with a digital readout.

This DRO makes setup a lot more convenient and accurate. When the Pantorouter is used as a

slot mortiser, the DRO makes cutting multiple mortise joints a breeze.

I have a similar DRO on my drill press and it's great when I want to drill holes of a precise depth. So I wanted the same feature for the Pantorouter plunge mechanism. These DROs are a bit pricey though. Since I only needed 6" (15cm) for the plunge, I just used a cheap $10 caliper instead. The noses are cut off and the bottom bit is held by a little metal bracket.

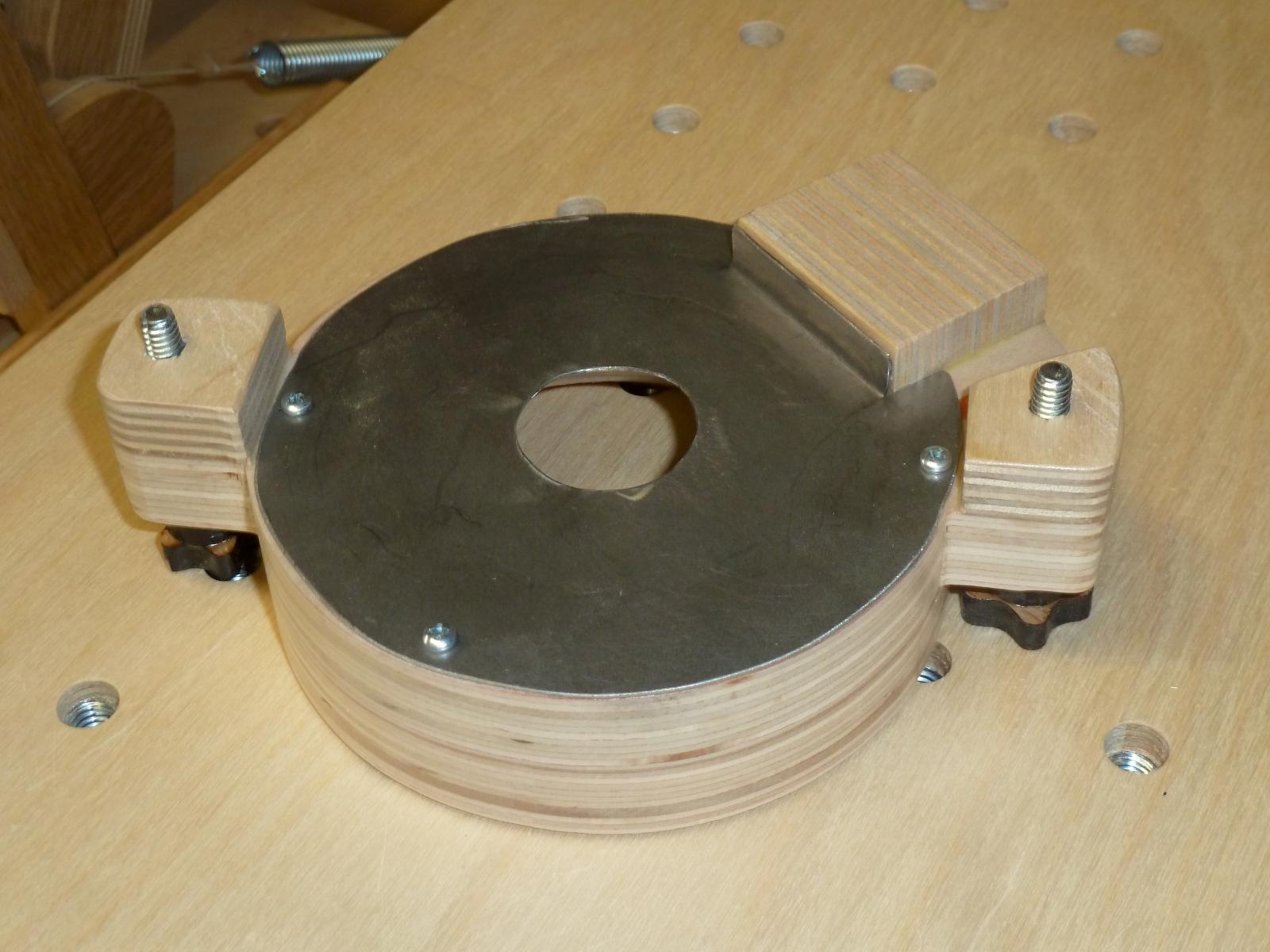

The Pantorouter produces an incredible amount of dust. It's not just the shavings

but especially the fine dust that concerned me. There is a Dylos particle monitor in my shop and

I guess it can make you a bit paranoid. So this is my attempt at dust collection. It's the

same depth as the collet nut, so it does not compromise plunge depth or view. It's also easy

to take off with just two thumb screws when the bit needs changing. I had plans to add a skirt but so far

it works well enough as is, and, as you mentioned, having good visibility of your work is important.

The bottom is made of a piece of sheet metal to keep the profile low. It's there to deflect

the cooling air that is coming out of the router. That air stream is the main reason why

the dust is going all over the place if there is not dust collection. I used a jig saw to

cut out that piece of sheet metal. The rest is just three layers of plywood.

More of Crasten's projects:

pantorouter

pantorouter Router lift

Router lift Pantograph

Pantograph Bandsaw

Bandsaw Jointer

Jointer