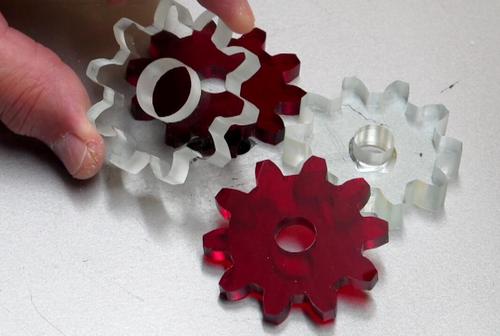

Making plexiglass gears

This article and video contributed by Ron Walters

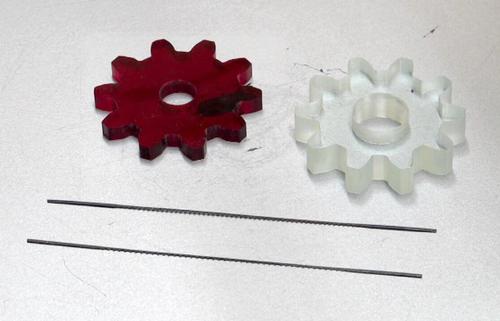

Plexiglas gears can be an attractive alternative for a lot of projects.

I like being able to see through the clear gears. The patterns for these

gears were made using Matthias's

Gear Template Generator Program.

Plexiglas gears can be an attractive alternative for a lot of projects.

I like being able to see through the clear gears. The patterns for these

gears were made using Matthias's

Gear Template Generator Program.

Material with a paper backing is preferred so you can attach your

pattern with glue.

Material with a paper backing is preferred so you can attach your

pattern with glue.

Cutting Plexiglas or plastic on the scroll saw can be a trial and error process until you find a combination of saw blade, saw speed, and material feed rate, which works for you. I tried several different blades and only a few gave satisfactory results.

The biggest problem is having the saw blade melt the plastic instead of

cutting it cleanly. This can be identified when you notice a lack of

cuttings leaving the saw cut. This generally indicates the plastic is

melting and the material is reconnecting or welding together directly

behind the saw blade.

The biggest problem is having the saw blade melt the plastic instead of

cutting it cleanly. This can be identified when you notice a lack of

cuttings leaving the saw cut. This generally indicates the plastic is

melting and the material is reconnecting or welding together directly

behind the saw blade.

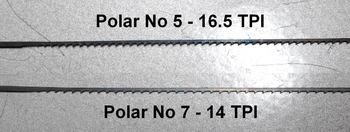

Two of the best blades were the Polar No. 5-16.5 TPI and the Polar No.

7-14 TPI.

Two of the best blades were the Polar No. 5-16.5 TPI and the Polar No.

7-14 TPI.

The cuttings become statically charged and the blower on the scroll saw

is not effective in keeping the pattern clear. This makes it difficult

to see where you are supposed to cut. Stopping a cut in the plastic can

produce a noticeable line so you should plan where you want to stop to

clear the chips away from the pattern so the line is less noticeable.

The cuttings become statically charged and the blower on the scroll saw

is not effective in keeping the pattern clear. This makes it difficult

to see where you are supposed to cut. Stopping a cut in the plastic can

produce a noticeable line so you should plan where you want to stop to

clear the chips away from the pattern so the line is less noticeable.

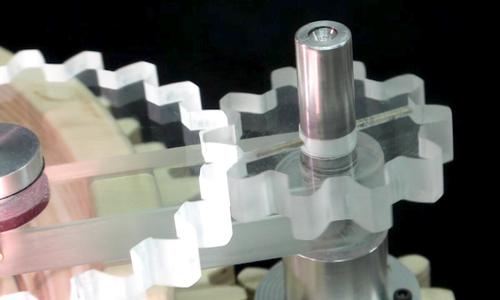

Practice several cuts on some scrap material until you are comfortable

with the process. Then it is pretty much the same as cutting out a

plywood gear. The cutting speed is fairly slow compared to plywood. I

aim the saw blade right down the center of the pattern line. The cut

edge of the teeth will not be polished but they are very smooth. I

generally have been able to run the gears right off the scroll saw

without the need to fine-tune them.

Practice several cuts on some scrap material until you are comfortable

with the process. Then it is pretty much the same as cutting out a

plywood gear. The cutting speed is fairly slow compared to plywood. I

aim the saw blade right down the center of the pattern line. The cut

edge of the teeth will not be polished but they are very smooth. I

generally have been able to run the gears right off the scroll saw

without the need to fine-tune them.

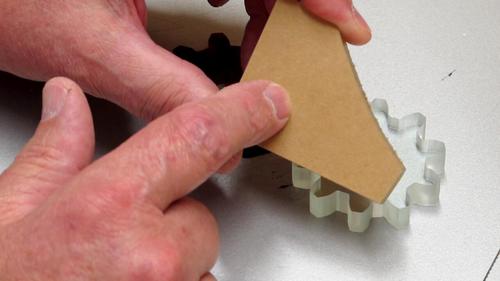

I used a scroll saw file to round over the corners of outside edges of

the teeth.

I used a scroll saw file to round over the corners of outside edges of

the teeth.

The adhesive of the backing material helps lubricate the saw blade. You will find it more difficult to make a cut if it does not have the backing material on it. Another trick is to put some packing tape on both sides of the plastic (over the pattern and over the backing material) as the adhesive in the packing tape lubricates the saw blade.

Do not remove the backing material until you are completely done working

on the gears. This will prevent them getting scratched.

Do not remove the backing material until you are completely done working

on the gears. This will prevent them getting scratched.

Some of this material seems like it may have been in a hot warehouse for some time. It is very difficult to remove the paper backing. I soak it in mineral spirits or kerosene. Then the backing comes off easily.

| Other gear projects by Ronald Walters: | See also: | ||||

Clock gear cutting |

Pin gear experiment |

Planetary gear drive |

Worm drive experiment |

Gear generator program | |