Destructively testing a cheap table

A friend, Bill Price, was getting rid of this

table and offered it to me. I figured I could use the melamine top for a workbench,

but when I checked it with a chisel, it turned out to be just painted hardboard.

It also had a noticeable sag to it, so I didn't consider it useful anymore.

So now what to do with it?

A friend, Bill Price, was getting rid of this

table and offered it to me. I figured I could use the melamine top for a workbench,

but when I checked it with a chisel, it turned out to be just painted hardboard.

It also had a noticeable sag to it, so I didn't consider it useful anymore.

So now what to do with it?

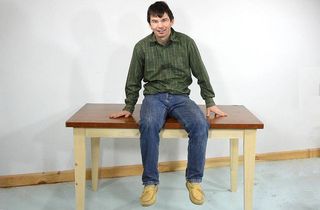

After I built my simple workbench, I tested it by taking a flying leap at it, and I also tested this simple table the same way. So I figured, why not subject this table to the same sort of test?

So why not put it to the same tests I put my own tables to? So I

put on some safety gear, put some padding underneath the table, and took

a flying leap at it.

So why not put it to the same tests I put my own tables to? So I

put on some safety gear, put some padding underneath the table, and took

a flying leap at it.

The table stood up to the first jump, but it was cracked. The second landing felt noticeably softer, but it still held, sort of. But on the third jump, it failed spectacularly.

The table top is just made out of 3 mm thick hardboard with a cardboard

honeycomb in between. I'm surprised how well it held up considering

how little material it's made of.

The table top is just made out of 3 mm thick hardboard with a cardboard

honeycomb in between. I'm surprised how well it held up considering

how little material it's made of.

While it's unfortunate that furniture should be made so cheaply, fact is, people throw out furniture, and if furniture is to be discarded, it makes more sense to use fewer resources to build it.

The corners where the legs screwed on were solid particle board.

I figure the legs might still be useful for something else, so

I removed them.

The corners where the legs screwed on were solid particle board.

I figure the legs might still be useful for something else, so

I removed them.

With the reinforced corners, it makes for a better table than a hollow core door would. Early in RIM (Blackberry)'s history, they made some of their desks out of hollow core doors. When I started there in 1993, there was still two tables made that way. They were even less sturdy than this table!

Linsay Wilson send me a link to a blog entry maknig X-rays of an ikea shelf - similar

construction:

X-rays of IKEA wood

Also a National Geographic video about Ikea's

Board on frame construction

also using cardboard honeycombs

More about building tables:

More about building

More about buildingwooden tables

Building a round

Building a rounddining table

Free simple table plans

Free simple table plansMore Projects on my Woodworking website.

Building a simple (and sturdy) table

Building a simple (and sturdy) table Flushing a running

Flushing a running

Bandsaw repair fail

Bandsaw repair fail