Stand for electric log splitter

The first time I saw an electric log splitter like this advertised

I didn't take it seriously. But my mom had some firewood that was split

too coarse, and she bought one of these on sale at Canadian Tire to

split the pieces smaller.

The first time I saw an electric log splitter like this advertised

I didn't take it seriously. But my mom had some firewood that was split

too coarse, and she bought one of these on sale at Canadian Tire to

split the pieces smaller.

It worked quite well at that. Playing around with it, the occasional piece that it had difficulty with was very hard to split with an axe too.

Having moved to the country, I bought one of these as well. This one supposedly has a five ton capacity.

These log splitters are unfortunately quite low to the ground. I had this one propped up on a dolly with two milk crates and a piece of plywood, but it was still a little too low. I wanted to make a better stand for it.

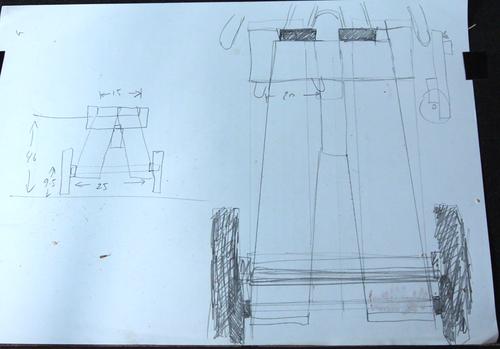

I sketched out a design (left, at left), and rummaged around for suitable wheels

and axles I found these wheels and axle from an old green compost bin.

The wheels are quite sturdy, so I decided to use them.

But the axle is a bit shorter than I had in mind, so I had to make the stand

a bit narrower. I made a 1:2.5 scale drawing (larger drawing at left)

I sketched out a design (left, at left), and rummaged around for suitable wheels

and axles I found these wheels and axle from an old green compost bin.

The wheels are quite sturdy, so I decided to use them.

But the axle is a bit shorter than I had in mind, so I had to make the stand

a bit narrower. I made a 1:2.5 scale drawing (larger drawing at left)

I made the stand mostly out of weathered old scraps of pressure treated

2x4 lumber.

I made the stand mostly out of weathered old scraps of pressure treated

2x4 lumber.

I cut a notch in a piece of 2x4 to fit around the legs on the motor end.

I cut a notch in a piece of 2x4 to fit around the legs on the motor end.

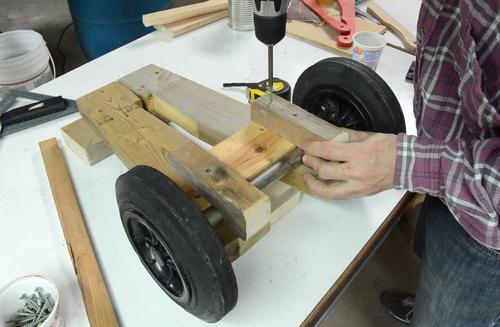

Laying out the end with the axle on it, then screwing part of it together.

Laying out the end with the axle on it, then screwing part of it together.

I cut a slot wide enough in the middle for a 2x6 to fit between the legs.

After bandsawing that, I screwed on the crosspiece for the bottom.

I cut a slot wide enough in the middle for a 2x6 to fit between the legs.

After bandsawing that, I screwed on the crosspiece for the bottom.

I made two wooden hooks to hold the axle against the stand.

I made two wooden hooks to hold the axle against the stand.

I made the other end of the stand with two notches on it to hold that

end of the log splitter.

I made the other end of the stand with two notches on it to hold that

end of the log splitter.

Then making sure the two ends of the stand are the same height.

Then making sure the two ends of the stand are the same height.

I screwed another piece of wood against the end with the axle, to make

a nice pocket for the legs to fit into.

I screwed another piece of wood against the end with the axle, to make

a nice pocket for the legs to fit into.

With the two ends of the stand held against the log splitter, I measured

how long the middle section needs to be.

With the two ends of the stand held against the log splitter, I measured

how long the middle section needs to be.

Attaching the middle section to the non-wheeled end, with an extra brace

to help hold it square.

Attaching the middle section to the non-wheeled end, with an extra brace

to help hold it square.

Then checking the fit, and tapping the 2x6 into the other stand to get the

spacing just right.

Then checking the fit, and tapping the 2x6 into the other stand to get the

spacing just right.

Screwing the 2x6 onto the wheeled end of the stand. I also added another brace

to the bottom of that end (like the other end) to stiffen it up after thius photo.

Screwing the 2x6 onto the wheeled end of the stand. I also added another brace

to the bottom of that end (like the other end) to stiffen it up after thius photo.

With the log splitter inserted into stand, I tipped it upright to raise it

onto the stand.

With the log splitter inserted into stand, I tipped it upright to raise it

onto the stand.

I originally hadn't planned on attaching the log splitter to the stand, but it was

easy enough to screw a piece of wood across this end to hold it down.

I originally hadn't planned on attaching the log splitter to the stand, but it was

easy enough to screw a piece of wood across this end to hold it down.

Then I had the idea of making a hook-shaped piece to hold the splitter's axle

to secure that end of the log splitter.

Then I had the idea of making a hook-shaped piece to hold the splitter's axle

to secure that end of the log splitter.

Testing it out with some of the biggest pieces I had around. It split them no problem.

It's a comfortable height for smaller pieces, and great for dropping the split

pieces into a wheelbarrow. For really big pieces, it might

be easier to lift them onto the splitter if it was slightly lower. But then again, I could

just take the log splitter of the stand if I had a lot of those.

Testing it out with some of the biggest pieces I had around. It split them no problem.

It's a comfortable height for smaller pieces, and great for dropping the split

pieces into a wheelbarrow. For really big pieces, it might

be easier to lift them onto the splitter if it was slightly lower. But then again, I could

just take the log splitter of the stand if I had a lot of those.

An annoyance with these log splitters is that the cylinder returns all the way to open

when you take your hands off the controls. But most pieces are not that long. I made a spacer

insert in one of the slots behind the block that pushes. This prevents it from going

all the way back, so I don't have to wait for it to come as far forward every time.

The log splitter just uses springs for the return, so preventing a full return is a safe

thing to do.

An annoyance with these log splitters is that the cylinder returns all the way to open

when you take your hands off the controls. But most pieces are not that long. I made a spacer

insert in one of the slots behind the block that pushes. This prevents it from going

all the way back, so I don't have to wait for it to come as far forward every time.

The log splitter just uses springs for the return, so preventing a full return is a safe

thing to do.

I also find that it helps to oil or grease the top and bottom of the cylinder casing.

The blue thing that pushes on the log slides along this, but it's pulled further down,

so there is a lot of "racking" force on it, which results in a lot of friction between

the bracket with the blue block on it and the slides. Oil makes it slide much easier.

It also makes it creak less, and less of a pop for pieces that split spontaneously.

I also find that it helps to oil or grease the top and bottom of the cylinder casing.

The blue thing that pushes on the log slides along this, but it's pulled further down,

so there is a lot of "racking" force on it, which results in a lot of friction between

the bracket with the blue block on it and the slides. Oil makes it slide much easier.

It also makes it creak less, and less of a pop for pieces that split spontaneously.

See also:

Making firewood with a bandsaw (video only)

Making firewood with a bandsaw (video only) Movable firewood shed made from palletes

Movable firewood shed made from palletes Burning sawdust in a

Burning sawdust in awood stove (video only)

Splitting logs for woodworking lumber

Splitting logs for woodworking lumber Needlessly complicated

Needlessly complicated Wood stove stainless steel hearth plate

Wood stove stainless steel hearth plate Chainsaw sharpening with an angle grinder

Chainsaw sharpening with an angle grinder