The lines on the template are lined up with a wire strung directly

above the saw blade. The saw blade is a special very thin fret saw blade.

The lines on the template are lined up with a wire strung directly

above the saw blade. The saw blade is a special very thin fret saw blade.

Pat Hawley writes:

Pat Hawley writes:Fret spacing template attached to the back of the fretboard.

The lines on the template are lined up with a wire strung directly

above the saw blade. The saw blade is a special very thin fret saw blade.

The lines on the template are lined up with a wire strung directly

above the saw blade. The saw blade is a special very thin fret saw blade.

I like putting binding on my fretboards to cover up the ends of the fret

tangs. Often I will use a contrasting wood for appearance, but using the

same wood as the fretboard results in a very "clean" look that I also like.

In this case, since the uke body was bound in rosewood, I decided to bind

the rosewood fretboard in the same wood and, in fact, I had saved an

off-cut from the fretboard for this purpose.

Here I'm rough cutting some strips from the fretboard off cut.

I like putting binding on my fretboards to cover up the ends of the fret

tangs. Often I will use a contrasting wood for appearance, but using the

same wood as the fretboard results in a very "clean" look that I also like.

In this case, since the uke body was bound in rosewood, I decided to bind

the rosewood fretboard in the same wood and, in fact, I had saved an

off-cut from the fretboard for this purpose.

Here I'm rough cutting some strips from the fretboard off cut.

Then I mounted them on a

support board and got them down to about 1 mm thickness in my drum sander.

Then I mounted them on a

support board and got them down to about 1 mm thickness in my drum sander.

Sanded bindings against the un-tapered fretboard

Sanded bindings against the un-tapered fretboard

Gluing the bindings to the fretboard (after I had tapered it).

Gluing the bindings to the fretboard (after I had tapered it).

I "pinned" the fretboard to the neck by drilling some small holes through a

couple of fret slots and into the neck. Then I inserted some nipped small

nails into the neck, leaving the tips sticking out so that I could re-locate

the fretboard and have it stay in place for final shaping of the neck. The

pins will also ensure that the fretboard won't move around when it comes

time to glue it in place.

I "pinned" the fretboard to the neck by drilling some small holes through a

couple of fret slots and into the neck. Then I inserted some nipped small

nails into the neck, leaving the tips sticking out so that I could re-locate

the fretboard and have it stay in place for final shaping of the neck. The

pins will also ensure that the fretboard won't move around when it comes

time to glue it in place.

This ukulele is going to have blue paua abalone fretboard inlays to go with

the rosette that was done in the same shell. My first step is to lay the

shell out on the fretboard the way I will want it inlayed.

This ukulele is going to have blue paua abalone fretboard inlays to go with

the rosette that was done in the same shell. My first step is to lay the

shell out on the fretboard the way I will want it inlayed.

The inlay consists of small slotted diamonds and the initials of the lovely Danielle

Allard for whom this ukulele is being built. Danielle already

plays one of my guitars

and sings in the Ottawa based group Go Long(!).

The inlay consists of small slotted diamonds and the initials of the lovely Danielle

Allard for whom this ukulele is being built. Danielle already

plays one of my guitars

and sings in the Ottawa based group Go Long(!).

I trace the inlay on to the fretboard using a sharp white pencil.

The tools for routing the pockets are a rotary tool with a small bit and a

router base attachment, an air blower that attaches to the router base to

blow away debris so the traces lines remain visible and, not shown in the

picture, some magnifying goggles and bright light so I can see. That little

air blower is the noisiest tool I own and I always have to wear ear plugs

when I'm doing inlay.

The tools for routing the pockets are a rotary tool with a small bit and a

router base attachment, an air blower that attaches to the router base to

blow away debris so the traces lines remain visible and, not shown in the

picture, some magnifying goggles and bright light so I can see. That little

air blower is the noisiest tool I own and I always have to wear ear plugs

when I'm doing inlay.

Cutting the pockets takes a steady hand. Sometimes the router wants to move

on its own into the wood so I have to be vigilant not to let it get away and

ruin the fretboard.

Cutting the pockets takes a steady hand. Sometimes the router wants to move

on its own into the wood so I have to be vigilant not to let it get away and

ruin the fretboard.

See inlay carving experiments with the pantograph.

When all the pockets are routed, I mix up some epoxy with rosewood dust and

glue in the shell with a generous amount of glue so it can sink in to all

the cracks around the shell. After the glue has cured, I will level it off

by first running through my drum sander just until the shell is exposed then

I will sand by hand up to 600 grit to get the shell nice and shiny and make

the fretboard ready for fretting.

When all the pockets are routed, I mix up some epoxy with rosewood dust and

glue in the shell with a generous amount of glue so it can sink in to all

the cracks around the shell. After the glue has cured, I will level it off

by first running through my drum sander just until the shell is exposed then

I will sand by hand up to 600 grit to get the shell nice and shiny and make

the fretboard ready for fretting.

Drilling the holes for the dots to go in the side of

the fretboard. I put it on a simple jig to make the fretboard level for

this under the drill.

Drilling the holes for the dots to go in the side of

the fretboard. I put it on a simple jig to make the fretboard level for

this under the drill.

The dots are just plastic rod that I shove in the hole

and sand level. It's the side dots, not the fret markers on top of the fret

board, that actually help the player get visually oriented as he or she goes

up the fretboard. For this purpose, only a couple are actually needed

although most guitars have more.

The dots are just plastic rod that I shove in the hole

and sand level. It's the side dots, not the fret markers on top of the fret

board, that actually help the player get visually oriented as he or she goes

up the fretboard. For this purpose, only a couple are actually needed

although most guitars have more.

Since I bound the fretboard, I had to file back the tangs on the end of

each fret so that only the top part of the fret goes over the binding.

Since I bound the fretboard, I had to file back the tangs on the end of

each fret so that only the top part of the fret goes over the binding.

I install them with a soft-faced hammer.

I install them with a soft-faced hammer.

When I sand back the bevel on the

frets, I also break the edge of the fretboard so it won't feel sharp for

the player. Even after that, it is necessary to file back the edges of the

frets further so that there are no sharp edges on them.

When I sand back the bevel on the

frets, I also break the edge of the fretboard so it won't feel sharp for

the player. Even after that, it is necessary to file back the edges of the

frets further so that there are no sharp edges on them.

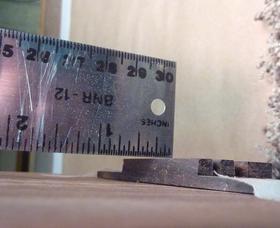

Once I have the fretboard fretted, I check the up and down angle of the

neck by running a ruler along the top of the frets and seeing how it would

match up to a bridge. As you can see in the first picture, the ruler was

hitting the bridge rather than clearing it

Once I have the fretboard fretted, I check the up and down angle of the

neck by running a ruler along the top of the frets and seeing how it would

match up to a bridge. As you can see in the first picture, the ruler was

hitting the bridge rather than clearing it

So I shaved and sanded the face

of the heel until the ruler cleared the bridge as shown here.

Actually, it was close enough that it probably would have worked

without this adjustment. The difference being in the first case I would have

had a saddle shorter in height. I prefer to have a "healthy" saddle height

in case the top bellies up a little. That way I can just sand the saddle

shorter.

So I shaved and sanded the face

of the heel until the ruler cleared the bridge as shown here.

Actually, it was close enough that it probably would have worked

without this adjustment. The difference being in the first case I would have

had a saddle shorter in height. I prefer to have a "healthy" saddle height

in case the top bellies up a little. That way I can just sand the saddle

shorter.

If, on the other hand, you run out of saddle height, you are forced to do a neck re-set which is a non-trivial repair.

When I was satisfied with the neck angle I glued the fretboard to the neck

using a big elastic for a clamp.

When I was satisfied with the neck angle I glued the fretboard to the neck

using a big elastic for a clamp.

After that I routed all the bindings with a

1/8" radius round over bit. This improves the look of the bindings and makes

the instrument much nicer to hold. I then did some sanding and put it

together for the last picture.

After that I routed all the bindings with a

1/8" radius round over bit. This improves the look of the bindings and makes

the instrument much nicer to hold. I then did some sanding and put it

together for the last picture.

Aside from the bridge, nut and saddle, the build part is complete. I will

start the finishing tomorrow. The curl in the koa should look great under

finish.

Aside from the bridge, nut and saddle, the build part is complete. I will

start the finishing tomorrow. The curl in the koa should look great under

finish.

See also: Matthias making the fretboard

Next: Pat finishing up the ukulele

![]()