Adjusting jointer knives

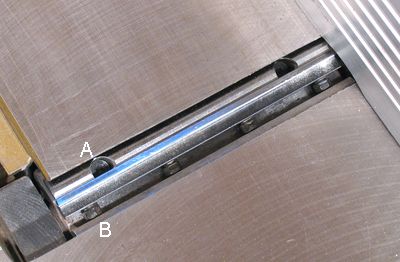

There are two designs of cutter heads in terms of how

the knives are adjusted. The type pictured at left is with jack screws (A)

behind the blades, which are used to lift the blades to the right height.

There are two designs of cutter heads in terms of how

the knives are adjusted. The type pictured at left is with jack screws (A)

behind the blades, which are used to lift the blades to the right height.

Another set of screws, seen from the side (B) are used to clamp the

blades in place. The heads of these screws push against the head, pressing the

bar against the blades. The blades are held in just by friction.

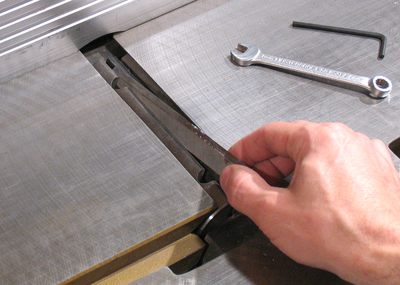

To remove the blades, start by loosening the four screws holding the bar in.

This is done with a small wrench. Pushing the wrench away from you loosens the screws.

Turn them until they are loose, and perhaps a half a turn further. Not loosening them

too far makes reinstalling them easier.

To remove the blades, start by loosening the four screws holding the bar in.

This is done with a small wrench. Pushing the wrench away from you loosens the screws.

Turn them until they are loose, and perhaps a half a turn further. Not loosening them

too far makes reinstalling them easier.

With all four screws loosened, the knife can be pulled out. It's easier to remove

the knife before removing the bar, as the slot is wider towards the bottom, and the

screws would have to be loosened more for the bar to come out first.

With all four screws loosened, the knife can be pulled out. It's easier to remove

the knife before removing the bar, as the slot is wider towards the bottom, and the

screws would have to be loosened more for the bar to come out first.

After removing the knife, the bar lifts out easily. The next step is to clean out

the slot, so that any dust in there won't affect the alignment when you

reinstall the knives.

After removing the knife, the bar lifts out easily. The next step is to clean out

the slot, so that any dust in there won't affect the alignment when you

reinstall the knives.

Once you have the knives out, presumably, you want the knives to get them sharpened.

Once you have your knives back from sharpening, it's time to put them back in.

Put the bar in first, then the knife. Next, tighten the four screws in the bar, and

then back them off a bit so that they make contact but aren't tight.

Once you have your knives back from sharpening, it's time to put them back in.

Put the bar in first, then the knife. Next, tighten the four screws in the bar, and

then back them off a bit so that they make contact but aren't tight.

Use a straightedge resting on the outfeed table to check the height. With an alan

key in the jack screw, and the straight edge right next to it, set the height of the

knifes so that they just touch the ruler at the highest point.

Set the height of the knives so that if you rest the ruler on the outfeed table, and turn the planer head by hand, it will pick up the ruler, and move it forward by 5 mm, or about 0.2". Measure it just above the jack screws. It's a bit of an iterative process, and I usually just leave the alan key in between checking.

For a typical 2.5" diameter cutter head on a 6" jointer, having the

ruler be moved by 5 mm works out to having the knives protrude 0.004" (0.1mm) above

the outfeed table. However, once you tighten the four screws to lock the blade in

place, the knife will actually come up a little bit, just from flexing in the

steel. On my jointer, after tightening, the ruler gets carried about 6 mm, which works

out to closer to about .0048" or 0.12 mm. When you adjust the blades, ignore this

change in height after tightening. After installing, adjusting and tightening

all three blades, check that they all come to the same height.

If they all came up by the same height after tightening, you are good to go.

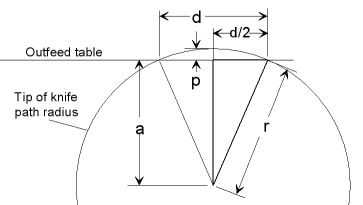

The amount of protrusion from how much the ruler gets carried can be calculated as follows

If r is the radius (not diameter) of the cutter head, and d is the distance

the ruler is carried, then the protrusion (p) of the knives from the outfeed

table can be calculated using the

Pythagorean theorem.

For a right angled triangle, the pythagorean theorem states that the sum of the squares

of the length of the sides forming a right angle is equal to the square of the length

of the diagonal.

Thus, for the geometry at right, a2 + (d/2)2 = r2

and a can be calculated as a = sqrt(r2-(d/2)2)

Where sqrt denotes square root.

And finally, p = r - a

Thus:

Protrusion p = r-sqrt(r2-(d/2)2)

For a 2.5" diameter cutter head, using inches, this works out as follows:

| Distance ruler pulled | Knife Protrusion | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Setting knives on a springs-backed knife style cutter head

The other type of planer head has no jack screws, but some springs behind the knives. This type of head is also used in most thickness planers.

Rather than a pair of jack screws, the jointer blades are pushed up two little

springs.

Rather than a pair of jack screws, the jointer blades are pushed up two little

springs.

On this type of cutter head, the blades are set in place using a jig. Thickness planers generally also use this approach, as there is no outfeed table to measure the blades from.

When you take the blade and the bar out, you might as well loosen the screws by

several turns, as getting the blade and bar back in against the spring tension

is very fiddly.

Also, ifthe springs are loose, take them out and put them aside, so they

won't fall out at the bottom when you turn the cutter head.

Your jointer should have come with a jig something like the one at left.

To use the jig, crank the infeed and outfeed tables down a bit to make room for it.

Your jointer should have come with a jig something like the one at left.

To use the jig, crank the infeed and outfeed tables down a bit to make room for it.

To set the knives, tighten and then back off the four screws holding the bar in place like you would with the head that uses jack screws. It should be possible to push the knife down, and have it come back up from the force of the springs.

While pressing the jig firmly down on the knife, tighten the screws. Really, just one screw tightened towards either end will do it. The screws are a bit hard to reach while the jig is in place.

Once you have all the blades set, wind the outfeed table back up, then adjust it so that the tips of the blades will drag a straightedge by about 5 mm, as described above. Hopefully, all the blades will be at a consistent height. If not, it's possible that you slipped with the jig while tightening the blade, so use the jig to check if any of your blades are set too high.

Sharpening jointer knives

Sharpening jointer knives(freehand)

To my Woodworking website

Sharpening jointer knives straight

Sharpening jointer knives straight Changing planer knives

Changing planer knives Does wood glue

Does wood glue Planer blade sharpening machine

Planer blade sharpening machine Homemade jointer

Homemade jointer