Sharpening router bits

I was routing some tracks for a marble game

experiment and was getting messy cuts and some burning. I figured, the

router bit is probably getting too dull.

I was routing some tracks for a marble game

experiment and was getting messy cuts and some burning. I figured, the

router bit is probably getting too dull.

To sharpen carbide cutters, you need a diamond wheel. Proper diamond wheels are

quite expensive. I once tried using a diamond tile saw blade.

It cut the carbide, but far too rough.

To sharpen carbide cutters, you need a diamond wheel. Proper diamond wheels are

quite expensive. I once tried using a diamond tile saw blade.

It cut the carbide, but far too rough.

I also tried a diamond stone one time, but that was slow and tedious.

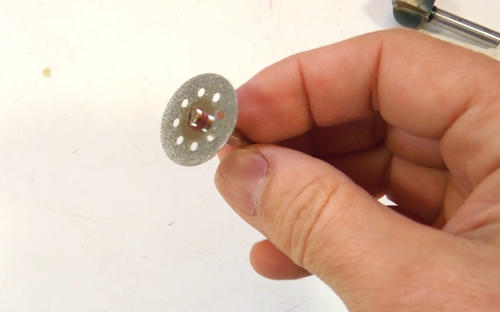

A reader, Andrew Scott, had suggested using a Dremel tool with a diamond wheel to sharpen carbide saw blades. Dremel tool diamond wheels are relatively cheap. I tried it, and it seemed to work. The diamond wheel was just fine enough for sharpening.

It's really quite simple. The most useful piece of information I can give

you is that it actually works!

It's really quite simple. The most useful piece of information I can give

you is that it actually works!

I first sharpened just the flat part of the cutter, and it cut much better after that.

Later, I accidentally routed into a screw in my jig, so I sharpened

again, this time sharpening the outside edge as well.

Although for round-over bits and other bits with inside curves,

a wheel really wouldn't work that well.

Later, I accidentally routed into a screw in my jig, so I sharpened

again, this time sharpening the outside edge as well.

Although for round-over bits and other bits with inside curves,

a wheel really wouldn't work that well.

I have since been told that dust from sharpening carbide

is hazardous to your health, so I'd recommend doing this outside

on a windy day. Though I suspect, as a hobbyist, only sharpening

the occasional bit, the dust exposure is still less than in

it would be for someone sharpening blades professionally,

even with protective equipment.

I have since been told that dust from sharpening carbide

is hazardous to your health, so I'd recommend doing this outside

on a windy day. Though I suspect, as a hobbyist, only sharpening

the occasional bit, the dust exposure is still less than in

it would be for someone sharpening blades professionally,

even with protective equipment.

And this is the jig I was using to route out those tracks.

I'm using my 3D pantograph,

with a 3D template to cut some ramps for a

marble toy experiment.

And this is the jig I was using to route out those tracks.

I'm using my 3D pantograph,

with a 3D template to cut some ramps for a

marble toy experiment.

You can see some lines along the grooves in the track pieces at right. Those are from pre-routing a square channel to make less work for the ball nose bit, but I routed some of those too deep.

More sharpening articles:

Chainsaw sharpening

Chainsaw sharpeningwith an angle grinder

See also:

Back to my woodworking website

Sharpening drill bits

Sharpening drill bits Sharpening bandsaw

Sharpening bandsaw Hand plane sharpening

Hand plane sharpening Modifying router bits

Modifying router bits Marble run building blocks

Marble run building blocks 3D router pantograph

3D router pantograph