Bill's drill press modifications

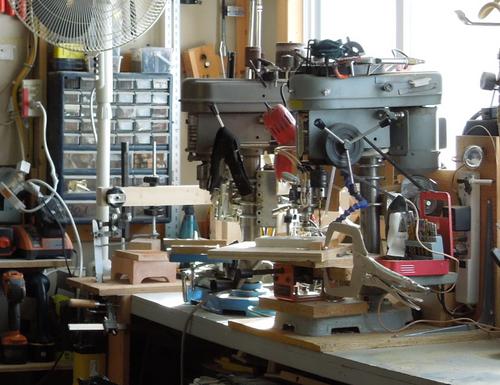

Bill says he has six drill presses (more than Jacques),

although only three of those are in his main shop.

Each of those has some modification made to it.

Bill says he has six drill presses (more than Jacques),

although only three of those are in his main shop.

Each of those has some modification made to it.

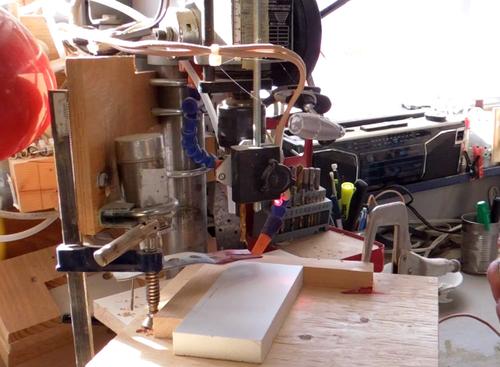

This drill press has a very elaborate modification. It's motorized and semi-automated,

with motorized plunge, pneumatic clamp, and air nozzle for blowing away the dust.

All this is controlled by a three button "remote" that Bill holds in his hand.

This drill press has a very elaborate modification. It's motorized and semi-automated,

with motorized plunge, pneumatic clamp, and air nozzle for blowing away the dust.

All this is controlled by a three button "remote" that Bill holds in his hand.

When drilling holes in the corner of large panels (such a signs), it's not always

possible to reach the drill press while holding the panel. So with this drill press

bill can hold the other end of the panel and use the remote to clamp, drill, and blow

away the dust. Very neat!

When drilling holes in the corner of large panels (such a signs), it's not always

possible to reach the drill press while holding the panel. So with this drill press

bill can hold the other end of the panel and use the remote to clamp, drill, and blow

away the dust. Very neat!

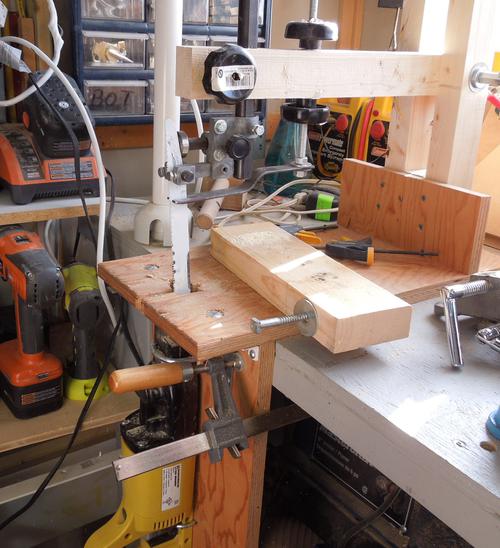

Another small drill press has a solenoid-operated Dremel drilling jig attached to it.

This is useful when drilling a lot of really tiny holes, like in a circuit board.

Another small drill press has a solenoid-operated Dremel drilling jig attached to it.

This is useful when drilling a lot of really tiny holes, like in a circuit board.

This setup actually only uses the table of the drill press, so this drill press functions as a normal when the table isn't swung over to the Dremel tool.

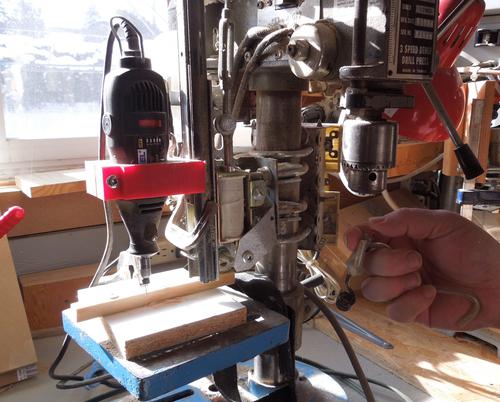

Bill also has a large drill press, to which he mounted an inexpensive

plastic caliper to act as a digital depth gauge.

Bill also has a large drill press, to which he mounted an inexpensive

plastic caliper to act as a digital depth gauge.

The nice thing about digital is that it can be zeroed at any point. So for example he can touch the drill to the material, zero it, and then the callipers indicate the depth he's drilling to.

The callipers are a cheap set of plastic digital callipers, bought for $10 on sale.

People sometimes mount a jigsaw to the bottom of a piece of plywood to use it

sort of like a bandsaw or scrollsaw. But Bill went one further, he mounted a big reciprocating

saw under a piece of plywood.

People sometimes mount a jigsaw to the bottom of a piece of plywood to use it

sort of like a bandsaw or scrollsaw. But Bill went one further, he mounted a big reciprocating

saw under a piece of plywood.

The top of the blade is steadied by a bandsaw blade guide that Bill had left over after upgrading to one of those fancy Carter blade guides.

The guide flips up so that the workpiece can be lowered over the blade.

The guide flips up so that the workpiece can be lowered over the blade.

Bill made this jig for experimenting with making something similar to bandsaw boxes, but without that extra cut that is always needed to get in and out with a bandsaw. The reciprocating saw can't follow curves like a bandsaw can, but Bill just uses a large drill to pre-drill the inside corners, so the reciprocating saw only needs to make straight cuts.

See also:

Bill Price's worksho and inventions |

Bill Price's motorized router lift |

Jacques Jodoin's amazing workshop |

Ryobi WDP 1850

|

Sharpening drill bits

|

To my Woodworking website