I like wooden drawer handles, but not to buy them. You usually end up with something a little bit expensive and perhaps a little bit dainty looking. So for the drawers in my workbench, I made my own handles.

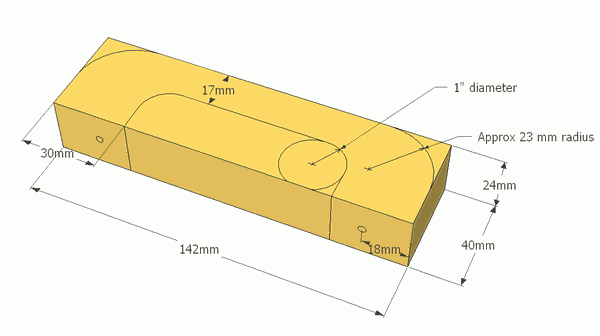

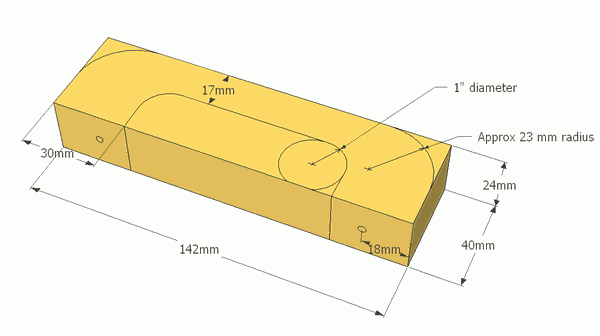

One of the hardest parts, I found, was coming up with a reasonable set of measurements for a handle that would look good. It's a bit deceptive marking it on a solid block of wood, as rounding the corners and edges will make the handle appear a little smaller than on the solid block of wood. Above are the dimensions I used for my handles. These may not be the exact size you would prefer, but it's a good idea to just make a handle and see what it feels like, and then modify the dimensions to adjust.

For the outside rounds, I find it expedient to just use the bottom of a plastic yogurt

cup to mark the arc. It's always handy to keep a few round things of various sizes

around the shop for uses like this.

For the outside rounds, I find it expedient to just use the bottom of a plastic yogurt

cup to mark the arc. It's always handy to keep a few round things of various sizes

around the shop for uses like this.

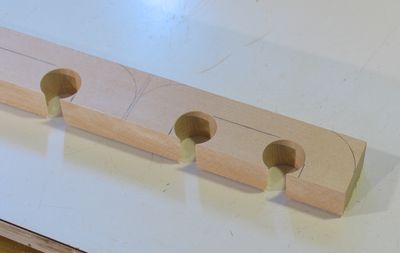

The inside corners I cut out by drilling a 1" diameter hole in the corners with

a forstner bit.

The inside corners I cut out by drilling a 1" diameter hole in the corners with

a forstner bit.

After drilling the holes, I cut out the insides of the handles with a bandsaw.

I find that I usually get just a little bit of a 'bump' where the bandsaw blade

breaks into the hole.

It's best to chisel this flat before routing the edges, because the router

will just follow this bump, and it becomes quite visible.

After drilling the holes, I cut out the insides of the handles with a bandsaw.

I find that I usually get just a little bit of a 'bump' where the bandsaw blade

breaks into the hole.

It's best to chisel this flat before routing the edges, because the router

will just follow this bump, and it becomes quite visible.

I prefer to rout out the inside edges before cutting the handles apart. That way,

I can keep my fingers a little bit further from the router.

I prefer to rout out the inside edges before cutting the handles apart. That way,

I can keep my fingers a little bit further from the router.

Next, it's time to cut the outside edges. I had to make a few relief cuts because

I didn't want to change to a narrow blade on my bandsaw.

Next, it's time to cut the outside edges. I had to make a few relief cuts because

I didn't want to change to a narrow blade on my bandsaw.

After cutting the outside round, I make the curve perfectly smooth and continuous on my

belt sander.

After cutting the outside round, I make the curve perfectly smooth and continuous on my

belt sander.

And finally, routing the outside edges....

And finally, routing the outside edges....

And drilling the holes for mounting. The holes are deep enough to almost come

out the front. When I mount them, I always choose a length of screw that will go

almost all the way through the handle, so that there is less risk of

the handles themselves splitting apart if pulled on really hard.

The holes are off center with respect to the face - they are closer to the middle

of the handle, where I can drill deeper without the drill coming out of the curved

part of the handle.

And drilling the holes for mounting. The holes are deep enough to almost come

out the front. When I mount them, I always choose a length of screw that will go

almost all the way through the handle, so that there is less risk of

the handles themselves splitting apart if pulled on really hard.

The holes are off center with respect to the face - they are closer to the middle

of the handle, where I can drill deeper without the drill coming out of the curved

part of the handle.

I always varnish the wooden handles separately from the drawers. Mostly, because that way,

I can finish the drawer fronts without the handles getting in the way.

It helps to put some screws into a board to hold the handles. That way, there's

less of a need to hold the handles by the varnish, and less varnish on the hands.

Though more often, I'm lazy and just support them on

triangular rails

I always varnish the wooden handles separately from the drawers. Mostly, because that way,

I can finish the drawer fronts without the handles getting in the way.

It helps to put some screws into a board to hold the handles. That way, there's

less of a need to hold the handles by the varnish, and less varnish on the hands.

Though more often, I'm lazy and just support them on

triangular rails

Here's how my hand fits into the handle. It's a comfortable fit.

Here's how my hand fits into the handle. It's a comfortable fit.

My drawer handles have an opening that is just slightly larger than what a typical commercial

wooden handle will have. Mostly, the opening is a little bit deeper. Though certainly,

the store bought handle looks a little dainty in comparison. Massive looking handles may

not be ideal for a kitchen drawer, but for a workshop, the style is really appropriate.

My drawer handles have an opening that is just slightly larger than what a typical commercial

wooden handle will have. Mostly, the opening is a little bit deeper. Though certainly,

the store bought handle looks a little dainty in comparison. Massive looking handles may

not be ideal for a kitchen drawer, but for a workshop, the style is really appropriate.

Making wooden drawer pulls (2019)

Making wooden drawer pulls (2019) Wooden doorknobs (2007)

Wooden doorknobs (2007) Workbench drawers (2008)

Workbench drawers (2008) Recessed drawer knobs (2014)

Recessed drawer knobs (2014)