Michael Grant told me about his homemade leaf vacuuming trailer.

That got me curious, so I had to visit him to check it out. And take pictures and videos, naturally!

Michael Grant told me about his homemade leaf vacuuming trailer.

That got me curious, so I had to visit him to check it out. And take pictures and videos, naturally!

Michael Grant told me about his homemade leaf vacuuming trailer.

That got me curious, so I had to visit him to check it out. And take pictures and videos, naturally!

Michael Grant told me about his homemade leaf vacuuming trailer.

That got me curious, so I had to visit him to check it out. And take pictures and videos, naturally!

The leaf vacuum is a a very simple affair. It consists of a blower, powered by a

used lawnmower engine, a 5" dust hose, borrowed from the wood shop dust extractor,

and some pieces of heating duct connecting the hose at either end.

The leaf vacuum is a a very simple affair. It consists of a blower, powered by a

used lawnmower engine, a 5" dust hose, borrowed from the wood shop dust extractor,

and some pieces of heating duct connecting the hose at either end.

An old bed sheet filters the air and keeps the leaves on the trailer.

Bed sheets are about the cheapest way to get fabric.

An old bed sheet filters the air and keeps the leaves on the trailer.

Bed sheets are about the cheapest way to get fabric.

Old lawnmower engines are useless for most applications because they have to be run with the shaft in a vertical orientation. But for this application, Michael just mounted the blower horizontally.

The hose is slightly longer than it needs to be, but that's because it's only borrowed for this purpose. The hose goes back on the dust extractor once the leaf vacuuming is done.

I'm amazed by how cleanly this contraption vacuums the lawn!

I'm amazed by how cleanly this contraption vacuums the lawn!

Michael says it only works with dry leaves. Wet leaves clog up the hose.

It does make for a bit of dust, but that all comes out the back, so no inconvenience

to the driver.

Michael says it only works with dry leaves. Wet leaves clog up the hose.

It does make for a bit of dust, but that all comes out the back, so no inconvenience

to the driver.

It didn't take long to fill the trailer. And the leaves, having been through the mower

and the blower, are partially shredded as well. This thing really packs them in!

It didn't take long to fill the trailer. And the leaves, having been through the mower

and the blower, are partially shredded as well. This thing really packs them in!

It's a good size lot that needs clearing. Michael says it's about six trailer loads

typically.

It's a good size lot that needs clearing. Michael says it's about six trailer loads

typically.

Here's a look inside the blower.

Here's a look inside the blower.

There's an impeller made from six half-inch nylon blades bolted

to an aluminium hub. The blades are bolted from the back using three 2" long 1/4" bolts

threaded straight into the nylon.

There's an impeller made from six half-inch nylon blades bolted

to an aluminium hub. The blades are bolted from the back using three 2" long 1/4" bolts

threaded straight into the nylon.

The vanes have a profile milled into them to make them lighter. Michael cut that profile with his CNC mill.

The original sides of the blower were made from aluminium soffit material. But with

the occasional pine cone, pebble, or walnut in the mix, that became quite dented.

The original sides of the blower were made from aluminium soffit material. But with

the occasional pine cone, pebble, or walnut in the mix, that became quite dented.

Before starting the leaves this year, Michael replaced the sides with 18-gauge

galvanized steel. That should be able to take much more abuse than the aluminium.

Before starting the leaves this year, Michael replaced the sides with 18-gauge

galvanized steel. That should be able to take much more abuse than the aluminium.

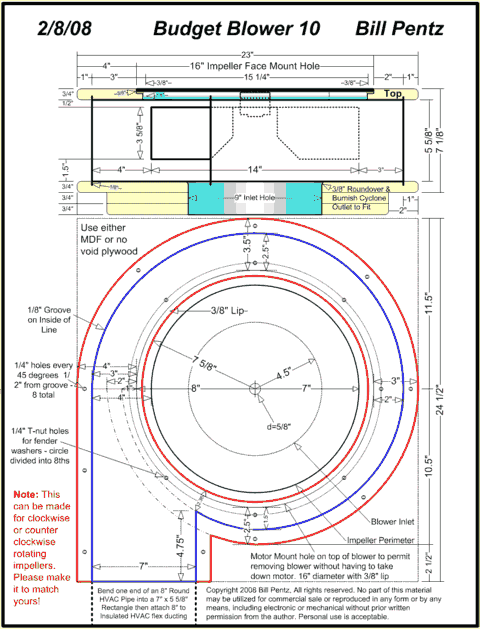

Michael used a

Bill Penz blower design to base his blower on.

Michael used a

Bill Penz blower design to base his blower on.

I asked Bill Penz for permission to use this image. Bill Penz added:

"Please warn then that if they donít use a material handling impeller (meaning plastic or aluminum) or if they hit a branch or rock they could get seriously hurt. Iíd also recommend making the blower with a double wall."

With the engine running at 3500 RPM, the tips of the fan blades travel at about 65 meters per second, or about 234km/h (146 MPH). That's fast, but not bullet fast, so a reasonably sturdy enclosure should be able to contain a catastrophic impeller failure.

Building a blower

Building a blower Anti-deer tree cage

Anti-deer tree cage Building a better

Building a better Weed root ball extractor lever (video)

Weed root ball extractor lever (video)