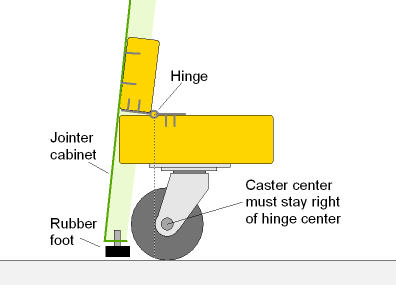

The mechanism consists of two casters attached to the bottom of a piece of wood that

can be tilted up by a hinge, as shown at left.

The mechanism consists of two casters attached to the bottom of a piece of wood that

can be tilted up by a hinge, as shown at left.

Many years ago, in my old workshop, I often found myself shoving the jointer out of the way, because the shop layout was just too cramped. Pulling it towards me was easier than pushing it, so I replaced the back two feet with fixed caster wheels, which made pushing the jointer much easier.

But in my new workshop, I wanted to be able to move the jointer even more easily.

So I came up with this clever mechanism to raise the front of the jointer onto two casters

when I wanted to move it.

The mechanism consists of two casters attached to the bottom of a piece of wood that

can be tilted up by a hinge, as shown at left.

The mechanism consists of two casters attached to the bottom of a piece of wood that

can be tilted up by a hinge, as shown at left.

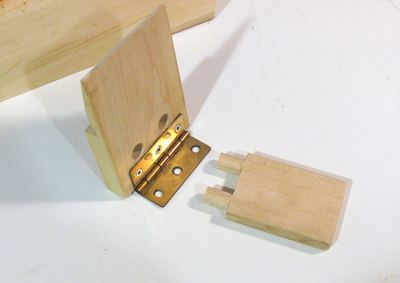

The mechanism consists of a piece of wood that is hinged, and has two swiveling casters

attached to the bottom of it. The core of the mechanism is shown at left.

The mechanism consists of a piece of wood that is hinged, and has two swiveling casters

attached to the bottom of it. The core of the mechanism is shown at left.

The part that is upright is screwed onto the inside of the jointer's stand. It supports

the hinges, which hold the bottom piece, which can be tilted upwards to retract the wheels,

and lower the jointer onto its rubber feet. The casters are screwed to the bottom of

this piece.

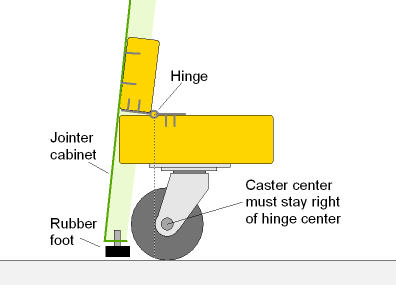

The image at left shows the bar tilted up, so that the jointer is resting on its own

rubber feet.

The image at left shows the bar tilted up, so that the jointer is resting on its own

rubber feet.

I came up with a simple latch to lock the lever down in the down position, so that the

jointer would stay up on its wheels. The latch just hooks onto the bottom of the

stand.

I came up with a simple latch to lock the lever down in the down position, so that the

jointer would stay up on its wheels. The latch just hooks onto the bottom of the

stand.

When the latch is released (jointer down on its feet), the latch just slides up against the

cabinet.

When the latch is released (jointer down on its feet), the latch just slides up against the

cabinet.

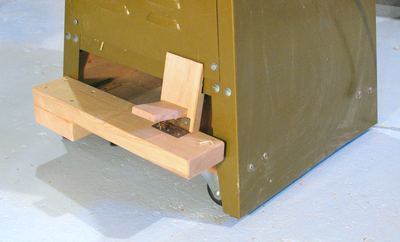

A more detailed view of the latching mechanism. I used an hold hinge to allow the

latch to pivot against the jointer.

A more detailed view of the latching mechanism. I used an hold hinge to allow the

latch to pivot against the jointer.

To push the latch against the machine, I used an old spring, which came from the battery

compartment of some old electronic gadget that used D sized batteries.

The latch itself is put together like this. I just drilled two holes in the latch,

and then hand-carved round tenons onto the piece that connects to it at a right angle.

This piece isn't just to hold the spring, it also serves as a foot pedal to open the latch

and lower the jointer back on its feet.

The latch itself is put together like this. I just drilled two holes in the latch,

and then hand-carved round tenons onto the piece that connects to it at a right angle.

This piece isn't just to hold the spring, it also serves as a foot pedal to open the latch

and lower the jointer back on its feet.

And finally, a shot from the side other than the mechanism. The fixed wheels are

on the left side. I could put these much closer to the edge, because they don't need to swivel.

As you can see, the other set of wheels swiveled inwards, are quite a ways in. Which is why

mounting non retractable casters right under the jointer would not provide a lot of stability.

That's why I mounted the castors outside the base for my mobile bandsaw base

And finally, a shot from the side other than the mechanism. The fixed wheels are

on the left side. I could put these much closer to the edge, because they don't need to swivel.

As you can see, the other set of wheels swiveled inwards, are quite a ways in. Which is why

mounting non retractable casters right under the jointer would not provide a lot of stability.

That's why I mounted the castors outside the base for my mobile bandsaw base

And a video demonstrating how it works:

Gordon's table saw lift

Gordon's table saw lift