Advantages of a brushless cordless drill

This is a sponsored post. I try not to let that affect me too much and see what I can get away with.

Canadian tire sent me this

Maximum brand

20-volt bushless cordless drill for review.

Canadian tire sent me this

Maximum brand

20-volt bushless cordless drill for review.

Please note: This is a sponsored review. I try not to let that affect my opinion and see what I can get away with.

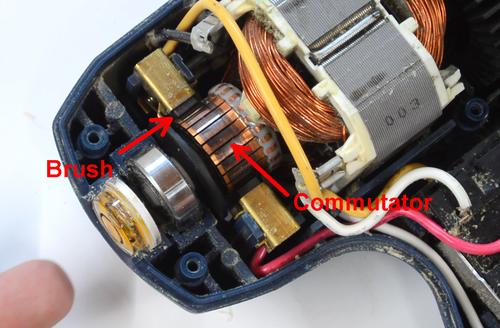

In most DC motors, there is a commutator and brushes like this to

continuously switch the connections to the electromagnets in the winding

to make continuous rotation. But these brushes add friction, and also

need to have a fair amount of electrical resistance to avoid excessive

sparking against the commutator.

In most DC motors, there is a commutator and brushes like this to

continuously switch the connections to the electromagnets in the winding

to make continuous rotation. But these brushes add friction, and also

need to have a fair amount of electrical resistance to avoid excessive

sparking against the commutator.

On a brushless motor, the coils are switched by transistors, which is more efficient. The physical arrangement is also different, with the coils stationary and the rotor consisting of a magnet.

With increased efficiency, you can get more work out of the same amount of battery. It's like having a bigger battery without the extra size and weight.

On one of my other drills, setting it to the low speed, it's quite

difficult to turn the chuck to spin the motor. The brushless drill

locks the motor when stopped to make it easier to spin the chuck.

But I could trick it into unlocking the motor by removing

the battery while the trigger was partially depressed.

Without the lock, even in low gear, it was much easier to spin

the chuck, though if

I spun it at any speed, it locked the motor again. My guess is

that the motor generates enough electricity when spun to activate

the internal circuitry, which in turn engages motor lock.

On one of my other drills, setting it to the low speed, it's quite

difficult to turn the chuck to spin the motor. The brushless drill

locks the motor when stopped to make it easier to spin the chuck.

But I could trick it into unlocking the motor by removing

the battery while the trigger was partially depressed.

Without the lock, even in low gear, it was much easier to spin

the chuck, though if

I spun it at any speed, it locked the motor again. My guess is

that the motor generates enough electricity when spun to activate

the internal circuitry, which in turn engages motor lock.

For both drills, spinning the chuck in high gear is easier because in high gear, the gearbox is at a lower gear ratio.

Playing around with the drill some more, I noticed it really

regulates the speed to compensate for load. Even when the trigger

is pressed only enough for low speed, if I grab the chuck

and try to stop it, it applies enough torque to keep the drill

turning at the same speed.

Playing around with the drill some more, I noticed it really

regulates the speed to compensate for load. Even when the trigger

is pressed only enough for low speed, if I grab the chuck

and try to stop it, it applies enough torque to keep the drill

turning at the same speed.

I made a sort of crank with a weight on it to check how well it

regulated the speed as the weight went around. It did go around at

constant speed, though the chuck has about 20 degrees worth of play or

backlash on it. When the weight goes down, the drill applies braking to

keep it from going too fast, but the braking is very jerky. Under normal

operation you wouldn't see this. The braking helps to slow the chuck

quickly when the trigger is released, but it's primary function

is to allow the drill chuck to be tightened when the drill is not

running. I originally thought the brake was elecronic (as mentioned

in the video), but Marius Hornberger has made a video that, among

other things explains

how the

mechanical chuck brake works

I made a sort of crank with a weight on it to check how well it

regulated the speed as the weight went around. It did go around at

constant speed, though the chuck has about 20 degrees worth of play or

backlash on it. When the weight goes down, the drill applies braking to

keep it from going too fast, but the braking is very jerky. Under normal

operation you wouldn't see this. The braking helps to slow the chuck

quickly when the trigger is released, but it's primary function

is to allow the drill chuck to be tightened when the drill is not

running. I originally thought the brake was elecronic (as mentioned

in the video), but Marius Hornberger has made a video that, among

other things explains

how the

mechanical chuck brake works

As for the speed regulation, at first I didn't think this feature was a very good idea — I usually rely on hearing the drill wail down a bit to give me feedback when I'm driving in screws.

Of course, for driving screws, there's an adjustable ratchet clutch to

set how tight you want it to screw before the clutch lets go,

but I have never ever used that feature on any drill.

Trying it out with some screws, it can be set so the clutch slips

once the screw is all the way in, provided that the wood is consistent

and provides the same resistance for every screw.

Of course, for driving screws, there's an adjustable ratchet clutch to

set how tight you want it to screw before the clutch lets go,

but I have never ever used that feature on any drill.

Trying it out with some screws, it can be set so the clutch slips

once the screw is all the way in, provided that the wood is consistent

and provides the same resistance for every screw.

Playing around with the drill some more, I realized the speed regulation

is a really useful feature.

For example, when starting a big drill or hole saw, I can go really

slow even if there is a lot of torque, without having to twitch the

trigger like I have to with my other drills.

Playing around with the drill some more, I realized the speed regulation

is a really useful feature.

For example, when starting a big drill or hole saw, I can go really

slow even if there is a lot of torque, without having to twitch the

trigger like I have to with my other drills.

I figure the speed regulation could also be handy for setting screws just right, even in the high gear (because I'm impatient and often use the high gear to drive wood screws).

I'm getting less fond of using an impact driver to drive screws - impact drivers, once they bog down, are very loud and slow. Most of the time, a drill will have enough torque, with less fuss.

It's also very useful to be able to go slow and still have lots of

torque when you know a drill is about to break through, especially

when drilling through metal.

It's also very useful to be able to go slow and still have lots of

torque when you know a drill is about to break through, especially

when drilling through metal.

By the way, when drilling a big hole in metal, it's best to drill a

pilot hole first, because the middle part of a metal drill bit isn't

very good at removing material. That way, you don't need to push

as hard to get the drill to engage.

By the way, when drilling a big hole in metal, it's best to drill a

pilot hole first, because the middle part of a metal drill bit isn't

very good at removing material. That way, you don't need to push

as hard to get the drill to engage.

I used these Maximum brand rills that Canadian Tire also sent to me.

they have "seven cutting edges" with the more complicated profile

on the tip of the bit. I have to say, for following an existing

pilot hole, this more complicated profile is at a disadvantage.

Examining the bit after drilling the hole, the titanium coating

had worn off the leading cutting edge, and one of the outside corners

of the bit had chipped.

No problem, I can

sharpen it, though after a few

sharpenings that fancy profile will be ground back to a regular one.

I used these Maximum brand rills that Canadian Tire also sent to me.

they have "seven cutting edges" with the more complicated profile

on the tip of the bit. I have to say, for following an existing

pilot hole, this more complicated profile is at a disadvantage.

Examining the bit after drilling the hole, the titanium coating

had worn off the leading cutting edge, and one of the outside corners

of the bit had chipped.

No problem, I can

sharpen it, though after a few

sharpenings that fancy profile will be ground back to a regular one.

My recommendation when buying drills: Don't pay extra for the fancy profile and the pretty titanium coating.

I also noticed the drill is fairly loud. Not a gear grinding sort

of loud, just a loud whine from the motor. It's louder

than this other non-brushless drill I'm holding. This is a bit

disappointing - brushless motors can be much quieter than brushed ones.

I also noticed the drill is fairly loud. Not a gear grinding sort

of loud, just a loud whine from the motor. It's louder

than this other non-brushless drill I'm holding. This is a bit

disappointing - brushless motors can be much quieter than brushed ones.

To be fair, the Maximum drill is bigger and can run faster, so perhaps that would be a reason for it to be a bit louder, but it's actually much louder than the other drill.

Although I was compensated for my participation, the views and opinions expressed herein represent my own and not those of Canadian Tire corporation or any other party and do not constitute financial, legal or other advice

The MAXIMUM line of tools is the new premium Canadian Tire store brand of tools, sold exclusively at Canadian Tire. www.canadiantire.ca/maximum

The drill came with an extra battery, charger, an extra handle to clip

to the drill to hold it better, a belt clip, a screwdriver bit,

and a soft carrying pouch to carry it all in (I much prefer the soft

carrying pouches to the hard cases).

The drill came with an extra battery, charger, an extra handle to clip

to the drill to hold it better, a belt clip, a screwdriver bit,

and a soft carrying pouch to carry it all in (I much prefer the soft

carrying pouches to the hard cases).

But ideally, I'd have a drill more like this one in a smaller, lighter format. Because most of the time, my small drill is enough for the job, and for bigger jobs, I just resorted to using a corded drill. But it will be convenient having a bigger corded drill too.

Overall, I think the speed regulation is the most interesting and useful feature of this drill. There have been times in the past where this feature would have been very useful.

Downsides of this drill are that it's heavy and loud. The ideal drill for me would be the size of some of my smaller cordless drills, but brushless, and quieter.

See also:

Back to my woodworking website.

Maximum brand tool bag and tap and die set

Maximum brand tool bag and tap and die set Sharpening drill bits

Sharpening drill bits Homemade power feeder

Homemade power feeder My "Ryokita" franken-drill

My "Ryokita" franken-drill Horizontal boring jig

Horizontal boring jig Ryobi WDP 1850

Ryobi WDP 1850 Why I don't use a drill press table

Why I don't use a drill press table LED vs. CF

LED vs. CF