So I thought it would be useful to write a short article about the physics

of bandsaw resawing and how to prevent the blade from wandering.

So I thought it would be useful to write a short article about the physics

of bandsaw resawing and how to prevent the blade from wandering.

I occasionally get emails from people who have trouble with resawing lumber

on their bandsaw.

The main problem people run into is that the blade

tends to wander off to the side.

So I thought it would be useful to write a short article about the physics

of bandsaw resawing and how to prevent the blade from wandering.

So I thought it would be useful to write a short article about the physics

of bandsaw resawing and how to prevent the blade from wandering.

To illustrate some of the concepts, I made a simple "model" of a bandsaw blade cutting through wood. I used sawdust on the table to model the board being cut. Each tooth, as it passes through the board, cuts out some wood chips, and carries them out of the cut.

But if we cut through much thicker stock, what works for a normal board no

longer works. With a really deep cut, there just isn't enough room

between the teeth to carry away all the sawdust produced by each

tooth on the way through.

Once the space between the teeth is full, some of the sawdust

gets squeezed into the kerf next to

the blade, which then causes more friction. The sawdust may be forced

more to one side than the other, which can lead to the blade

wandering.

But if we cut through much thicker stock, what works for a normal board no

longer works. With a really deep cut, there just isn't enough room

between the teeth to carry away all the sawdust produced by each

tooth on the way through.

Once the space between the teeth is full, some of the sawdust

gets squeezed into the kerf next to

the blade, which then causes more friction. The sawdust may be forced

more to one side than the other, which can lead to the blade

wandering.

The solution, it would seem, is to cut slower. But as the blade gets slightly dull, the tip of each tooth becomes slightly rounded instead of a perfect point. When the tooth isn't pushed into the wood fast enough, that round causes the tooth to just rub on the edge of the cut instead of biting into the wood. So really slow feed rates only work when the blade is very sharp.

A solution to this problem is to use a blade with fewer teeth on it. This

allows for more room between the teeth for the sawdust. But it also means

that for the same bite of each tooth, less power, and less feed

pressure pushing the wood against the blade is needed.

A solution to this problem is to use a blade with fewer teeth on it. This

allows for more room between the teeth for the sawdust. But it also means

that for the same bite of each tooth, less power, and less feed

pressure pushing the wood against the blade is needed.

But for very deep cuts, such as when resawing wood that is 30 cm (12") wide, even with a 2 TPI (tooth per inch) blade, there are 24 teeth in the wood at the same time.

Those 24 teeth add up to quite a lot of power and feed pressure.

The feed pressure is like pushing straight against the front of the blade.

The feed pressure is like pushing straight against the front of the blade.

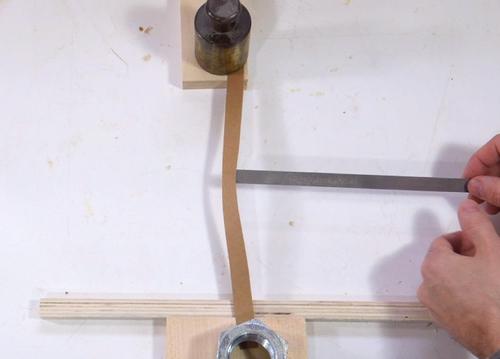

In this "model", the strip of cardboard is the blade, and I'm pushing against it with a steel ruler. Under pressure, the strip of cardboard has a tendency to buckle away from the force. This starts with the front edge of the cardboard buckling sideways.

This sideways buckling can be countered by pulling both ends of the cardboard strip so it's really right -- essentially, more blade tension. But even with the blade under tension, once the feed pressure exceeds a certain amount, (what is referred to as the "beam strength" of the blade), it will still want to buckle sideways.

Think of the blade like an upright "beam" supported by the upper and lower blade guides,

and the wood pushing against it. With a beam, this push

causes a bending moment, which causes compression along the edge

we are pushing against, and tension along the opposite edge.

If the beam consists of just a thin strip of metal, like a bandsaw

blade, compression will cause that side to buckle.

What holds the blade straight is tension,

but once the blade's tension is canceled out by the compression

from the beam effect, there is very little to

hold that edge straight. Once the front edge is under pressure,

it will start to buckle by twisting away from the force.

Think of the blade like an upright "beam" supported by the upper and lower blade guides,

and the wood pushing against it. With a beam, this push

causes a bending moment, which causes compression along the edge

we are pushing against, and tension along the opposite edge.

If the beam consists of just a thin strip of metal, like a bandsaw

blade, compression will cause that side to buckle.

What holds the blade straight is tension,

but once the blade's tension is canceled out by the compression

from the beam effect, there is very little to

hold that edge straight. Once the front edge is under pressure,

it will start to buckle by twisting away from the force.

You probably have experienced this with a hack saw already. When

starting a cut, the blade may have a tendency to twist sideways,

or sort of "fall over"

You probably have experienced this with a hack saw already. When

starting a cut, the blade may have a tendency to twist sideways,

or sort of "fall over"

Applying more down force on the saw makes it worse. But adding more tension to the blade make this happen much less.

Wider blades help in this regard. For the same amount of tension, a blade

twice as wide will have twice as much beam strength. But at the same time,

wider blades can take more tension. At left - a 1/4" wide 10 TPI blade,

a 1/2" wide 4 TPI blade, and a 3/4" (19 mm) wide 2 TPI blade.

Wider blades help in this regard. For the same amount of tension, a blade

twice as wide will have twice as much beam strength. But at the same time,

wider blades can take more tension. At left - a 1/4" wide 10 TPI blade,

a 1/2" wide 4 TPI blade, and a 3/4" (19 mm) wide 2 TPI blade.

Some people prefer really wide blades for resawing, but for my purposes, 3/4" has always been wide enough. Even 1/2" wide blades have enough beam strength for resawing if sufficiently tensioned. The 3/4" wide blade on the right is the one I used for cutting up a log. Though I had previously cut up a short log with just a 1/2" 3 TPI blade. With just a 1 HP motor on the saw, but a very sturdy tensioning mechanism, lack of motor power was a bigger limitation than beam strength of the blade.

If you find that your blade has gotten too dull to resaw, that doesn't mean the blade is too dull for other work. Once the blade is too dull to cut through 30 cm (12") of material, it will still cut through 15 cm (6") of material just fine. You will have an easier time resawing if you cut your boards to the width you need them before resawing.

Too heavy a blade around too small a wheel will cause the blade to fail from prematurely from metal fatigue. If you run a blade meant for a portable sawmill around 14" (35 cm) wheels or smaller, don't expect it to last very long. I'm pushing the limits with my 14" bandsaw/sawmill, but I don't use sawmill blades on it either.

On that topic this guys YouTube video is interesting. He's using a sawmill blade on 14" wheels. Bound to fail eventually. A blade guard wouldn't hurt either!

When I got my 26" bandsaw built far enough that I could try some resawing with it, I cut up a big piece of ironwood (American hophornbeam). I didn't get far into it when the blade snagged on the wood and came off the saw! Fortunately without damaging anything. I had the blade tension too low, so once it snagged, it slipped on the wheels, and that caused it to slide off the wheels. I added more tension and cut again.

But I'd still got these occasional loud "bang" sounds where the blade got snagged for a fraction of a millisecond and immediately tore itself loose. Each time, you could see all the wood and the sawdust on the table bounce, as if I hit a hammer down on the piece of wood.

I spent some time investigating this. The problem only occurred with very hard woods like the ironwood or some hard maple (sugar maple). Softer woods cut fairly smoothly.

The blade I was using was a very sharp hook toothed blade, and I believe what is happening is that the hook sometimes really grabs onto the wood and pulls the blade deeper into the wood. With softer woods, the fibers just bend out of the way a bit so the teeth don't hook onto the blade, but with very hard woods, the fibers don't yield, so the teeth can really hook on.

I assume this would be less of a problem for hook tooth blades on a sawmill because logs are milled before drying, and wood is softer before drying.

The problem is made less bad if the grain of the wood points down slightly towards the teeth, so the teeth have less to hook on to. Also, I wasn't getting this with a different blade that didn't have as much of a hook to it.

Frequently asked bandsaw questions

Wooden bandsaw riser block (2017)

Wooden bandsaw riser block (2017) Bandsaw blade

Bandsaw blade Homemade bandsaw/sawmill (2011)

Homemade bandsaw/sawmill (2011) Why bandsaw blades

Why bandsaw blades Sharpening bandsaw

Sharpening bandsaw Bandsaw on a dolly sawmill (2017)

Bandsaw on a dolly sawmill (2017) 20" bandsaw build (2016)

20" bandsaw build (2016)