Glue tests - examining the failures

After dong my glue strength tests, I did some close examination of the crossgrain joints in hard maple. I rigged up a small lens to my digital camera to act as a macro photo lens. Many of the close-ups cover an area of just one centimeter across.Gorilla glue

This is how most of my glue tests with Gorilla glue on hard maple looked like after breaking.

This is how most of my glue tests with Gorilla glue on hard maple looked like after breaking.

One of the features of Gorilla glue is that it expands about three times its volume as it cures. I think the idea is that it will ensure that the joint is completely filled with glue.

I used liberal amounts of glue. Most of this glue was squeezed out during clamping. The squeezed out glue expanded as it cured, so the amount of squeezed out glue really increased.

Breaking off some of the squeeze-out and having a closer look reveals that the squeeze-out had turned into

a sort of foam. This foam is mostly air, and can be broken off with the fingers. So the very expanded

squeeze-out is actually not very strong.

Breaking off some of the squeeze-out and having a closer look reveals that the squeeze-out had turned into

a sort of foam. This foam is mostly air, and can be broken off with the fingers. So the very expanded

squeeze-out is actually not very strong.

Examining the surface of the joint very closely, there was always a substantial part of the joint

that had a texture as seen at left. Even inside the clamped part of the joint, it bubbled up.

Examining the surface of the joint very closely, there was always a substantial part of the joint

that had a texture as seen at left. Even inside the clamped part of the joint, it bubbled up.

My guess is that as long as there is a significant amount of glue in the joint, it will bubble up and displace solid glue with much weaker bubbled up glue foam.

My view is that to get the best joints with Gorilla glue, you need to minimize the bubble squeeze-out. This means the joints need to be cut very very accurately so that the glue layer in the joint is very thin. But if you make your joints super accurate in the first place, then you don't need a glue that expands. I think Gorilla glue would be a better glue if it didn't foam up to "expand". My guess is that they couldn't figure out how to make it not foam and instead called this problem a "feature".

Some of the test joints with gorilla glue had areas where the maple grain was torn out substantially.

These were not areas that were full of bubbles. My guess is that those areas that were fortunate enough

to cure with a thin layer of solid glue did quite well. But what started out as solid glue

in most joints was often displaced by bubbles, which I think leads to very inconsistent

performance of this glue.

Some of the test joints with gorilla glue had areas where the maple grain was torn out substantially.

These were not areas that were full of bubbles. My guess is that those areas that were fortunate enough

to cure with a thin layer of solid glue did quite well. But what started out as solid glue

in most joints was often displaced by bubbles, which I think leads to very inconsistent

performance of this glue.

Titebond 3

All of my tests with Titebond 3 had some fibers torn out of one piece and stuck to the other piece.

So the glue was definitely stronger than the wood. I only saw this sort of transfer on some parts of

the joints.

All of my tests with Titebond 3 had some fibers torn out of one piece and stuck to the other piece.

So the glue was definitely stronger than the wood. I only saw this sort of transfer on some parts of

the joints.

Often, right in the middle of the joints, there is no sign of damage to the wood at all.

Often, right in the middle of the joints, there is no sign of damage to the wood at all.

On gluing up the Titebond 3 joints, I found that they had much less of a tendency to slip around than with my other glues. My theory with the Titebond 3 is that Titebond 3, being the runniest of the glues that I used and with a closed grain wood like maple maybe the glue actually was squeezed out sufficiently that there wasn't enough of it left in the joint to bond evenly.

Carpenter's glue

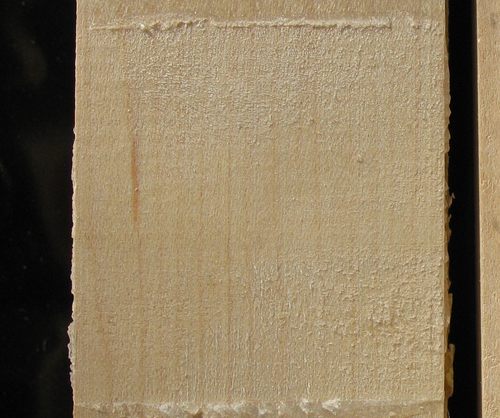

My Carpenters glue test pieces mostly looked like this. The surfaces all looked smooth, with

no tearout of fibers from the wood. Both sides looked like they had glue on them.

So it looks like the glue just plain failed. The breaking forces with Carpenter's glue were

less than with the other glues, so this makes sense.

My Carpenters glue test pieces mostly looked like this. The surfaces all looked smooth, with

no tearout of fibers from the wood. Both sides looked like they had glue on them.

So it looks like the glue just plain failed. The breaking forces with Carpenter's glue were

less than with the other glues, so this makes sense.

Weldbond

The Weldbond samples all looked about like the photo at left. There was relatively minimal tearing

of fibers out of the wood, suggesting that the glue wasn't quite strong enough to tear fibers

out of the hard maple.

The Weldbond samples all looked about like the photo at left. There was relatively minimal tearing

of fibers out of the wood, suggesting that the glue wasn't quite strong enough to tear fibers

out of the hard maple.

A close-up of the joint surface after breaking it.

A close-up of the joint surface after breaking it.

Examining the surfaces from the Weldbond tests, it doesn't suggest that Weldbond would be stronger than the other glues. So it's a bit odd that Weldbond won the crossgrain joint tests in hard maple.

My interpretation is that Weldbond is probably not quite as strong as Titebond 3 or Gorilla glue could theoretically be. But neither Gorilla glue nor Titebond 3 bonded ideally throughout every joint, but the Weldbond performed up to its full capacity. The fact that Weldbond retains a minor amount of flexibility after drying may have helped it too.

But that leaves the question - what good is a super strong glue that rarely performs to its full potential? Most furniture joints would probably be under less ideal circumstances than two pieces of wood crossing at right angles. It seems the more I investigate glues, the less clear things get.

Back to my glue strength tests