This project started when Rachel said "Now I have to cut

the cake into squares or triangles". My immediate thought was

"why not cut it into circles, or hexagons?"

This project started when Rachel said "Now I have to cut

the cake into squares or triangles". My immediate thought was

"why not cut it into circles, or hexagons?"

This project started when Rachel said "Now I have to cut

the cake into squares or triangles". My immediate thought was

"why not cut it into circles, or hexagons?"

This project started when Rachel said "Now I have to cut

the cake into squares or triangles". My immediate thought was

"why not cut it into circles, or hexagons?"

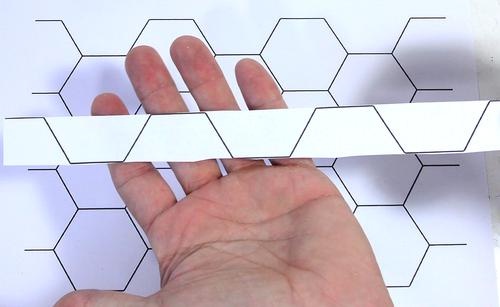

This got me thinking about a good method of cutting a cake into a

hexagon honeycomb pattern. The easiest I figured, was to make a knife that

snakes through the honeycomb pattern as shown on the strip of paper

at left.

This got me thinking about a good method of cutting a cake into a

hexagon honeycomb pattern. The easiest I figured, was to make a knife that

snakes through the honeycomb pattern as shown on the strip of paper

at left.

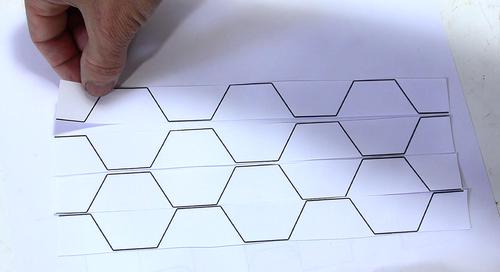

If you line up a series of cuts like that, you get a honeycomb pattern.

If you line up a series of cuts like that, you get a honeycomb pattern.

So I had to try this out. I ordered a strip of 26-gauge stainless steel, 2 1/4" (57 mm) wide, from the Metal Supermarket. 26-gauge is 0.019" or 0.48 mm thick.

Before bending, I sharpened one edge and smoothed the ground edge

on my buffing wheel.

Before bending, I sharpened one edge and smoothed the ground edge

on my buffing wheel.

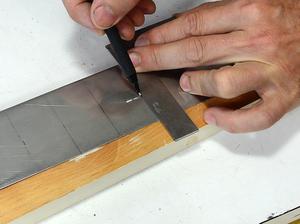

Then I very carefully marked 3 cm increments on both sides,

first measuring then drawing a line across with a square.

Then I very carefully marked 3 cm increments on both sides,

first measuring then drawing a line across with a square.

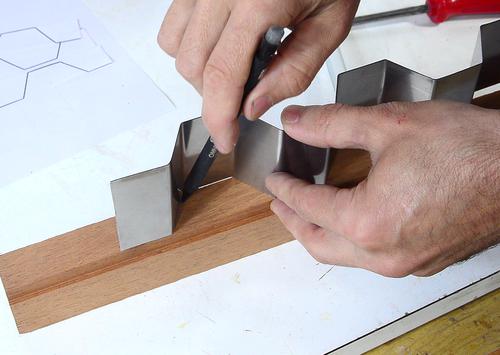

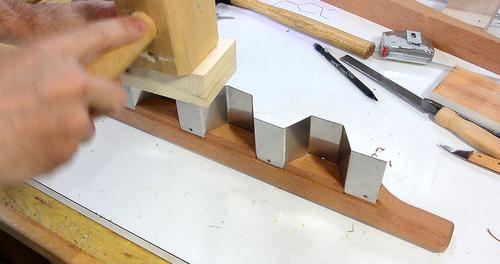

A sheet metal brake would be ideal for bending, but I don't have one.

I often bend this sort of thing in a vise, but with a strip this long

and wide, the vise won't work.

A sheet metal brake would be ideal for bending, but I don't have one.

I often bend this sort of thing in a vise, but with a strip this long

and wide, the vise won't work.

So I made a block of wood to clamp onto the strip.

I then hand-bend the strip by pushing it against a block of wood in

the vise, checking that I have it at the right angle.

I then hand-bend the strip by pushing it against a block of wood in

the vise, checking that I have it at the right angle.

After each bend I move the block of wood to the next line. When I have

to bend it in the opposite direction, I unclamp the block of wood and slid

it on the other way. This way, I'm always bending in the same direction

with respect to my block of wood, hoping to avoid inconsistencies.

After each bend I move the block of wood to the next line. When I have

to bend it in the opposite direction, I unclamp the block of wood and slid

it on the other way. This way, I'm always bending in the same direction

with respect to my block of wood, hoping to avoid inconsistencies.

I had to switch to a taller block of wood in the vise once the bent portion

became a bit longer. Here making the last bend.

I had to switch to a taller block of wood in the vise once the bent portion

became a bit longer. Here making the last bend.

I marked how wide the knife pattern is on a piece of mahogany.

I marked how wide the knife pattern is on a piece of mahogany.

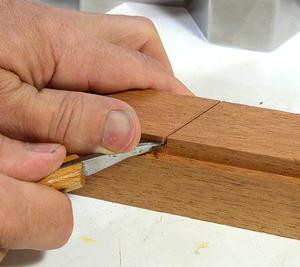

I cut a shoulder on either side to help mount the strip.

I cut a shoulder on either side to help mount the strip.

Marking where the knife blade needs to go through the wood.

Marking where the knife blade needs to go through the wood.

My dozuki saw makes a kerf that is just wide enough to slip

the knife blade into, though I had to cut away a slight bit

at the corners because my bends were slightly rounded.

My dozuki saw makes a kerf that is just wide enough to slip

the knife blade into, though I had to cut away a slight bit

at the corners because my bends were slightly rounded.

After making a cut, I partly inserted the blade and marked where the next

cut needs to go, then cut that, fit the blade again, and marked the next

one, and so on for every cut.

After making a cut, I partly inserted the blade and marked where the next

cut needs to go, then cut that, fit the blade again, and marked the next

one, and so on for every cut.

I cut away parts of the end of the wood to sort of shape handles.

I cut away parts of the end of the wood to sort of shape handles.

Then rounding the edges with a 1/2" round bit on my router table.

Then rounding the edges with a 1/2" round bit on my router table.

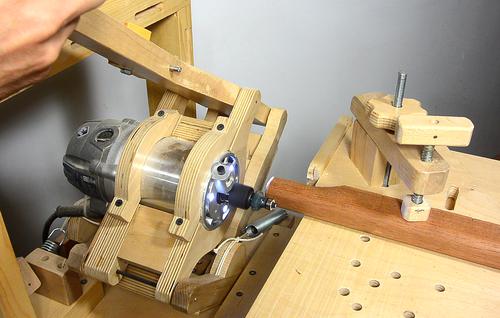

I used a 1/4" roundover bit to round the corners on the end. The easiest

way to do this was with my

pantorouter, though I'm not using

any templates, just relying on the bit's guide bearing.

I used a 1/4" roundover bit to round the corners on the end. The easiest

way to do this was with my

pantorouter, though I'm not using

any templates, just relying on the bit's guide bearing.

I also rounded over parts of the bottom of the handle that would be exposed after the blade is mounted with a knife.

I drilled some mounting holes along the edge of the blade.

I drilled some mounting holes along the edge of the blade.

Then inserting the blade. This was the first time I pushed it all

the way in. A tight fit, requiring a block of wood and a mallet to get

it all the way in.

Then inserting the blade. This was the first time I pushed it all

the way in. A tight fit, requiring a block of wood and a mallet to get

it all the way in.

Then pre-drilling holes in the handle and screwing it on with

some stainless steel screws.

Then pre-drilling holes in the handle and screwing it on with

some stainless steel screws.

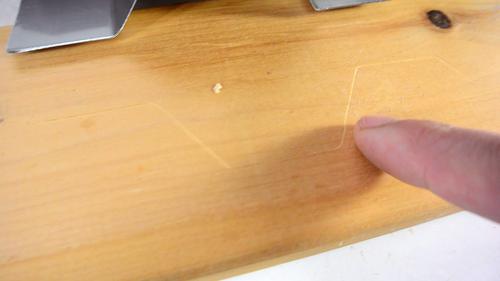

Testing the knife by pressing it down on some pine.

Testing the knife by pressing it down on some pine.

I had actually shaped the handle to have a slight curve on the bottom of it so that the knife can be rocked back and forth a bit for cases where it needs to slice through some tough cake or pizza bottom.

It left a nice indentation in the pine. so I'm confident that it can

slice any cake.

It left a nice indentation in the pine. so I'm confident that it can

slice any cake.

Finally testing it on some cake. Actually, this one is really banana

bread, but Rachel was kind enough to make it in a cake pan so I could

try this knife on it.

Finally testing it on some cake. Actually, this one is really banana

bread, but Rachel was kind enough to make it in a cake pan so I could

try this knife on it.

After each cut, I flip the knife around to get the right orientation for the next cut.

It works quite well on the banana bread. Though any sort of cake with

a pastry filling probably wouldn't do so well.

It works quite well on the banana bread. Though any sort of cake with

a pastry filling probably wouldn't do so well.

I initially thought of this knife as more of a novel but useless invention. But it could be quite useful for a catering business, just to offer brownies or whatever in a more novel shape.

Unfortunately, I don't have the time to make these for sale, though it would be cool if some manufacturer would be interested in making these.