Chain mortiser

Kurt's "Haffner" chain mortiser is one of those cast iron woodworking machines

from the days before globalisation.

Kurt's "Haffner" chain mortiser is one of those cast iron woodworking machines

from the days before globalisation.

A chain mortiser is another approach for making a "square hole", mortise. A chain mortiser works a lot like a chain saw in that it is plunged into the wood. But unlike a chain saw, the blade is straight, and the chain is designed to make a wider cut with a very square profile.

The advantage of a chain mortiser over other types of mortisers is that it can remove material quite fast, and it can plunge very deep. For this reason, portable chain mortisers are often used for post and beam building construction. This chain mortiser is a stationary tool designed to be used in a woodworking shop.

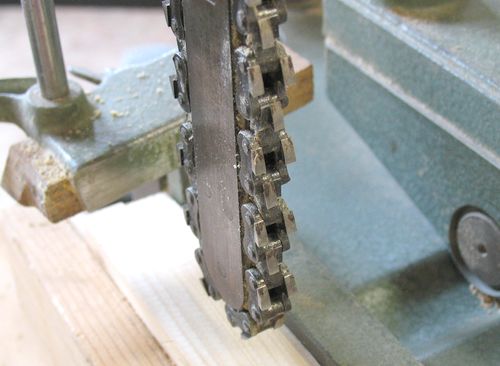

This picture shows the chain mortiser's drive sprocket. The chains sprocket, and bar that the

chain runs on can be changed over for different sized mortises.

This picture shows the chain mortiser's drive sprocket. The chains sprocket, and bar that the

chain runs on can be changed over for different sized mortises.

A close-up view of the cutting chain. The chain has several rows of teeth to make sure

that the profile of the cut is smooth and square.

A close-up view of the cutting chain. The chain has several rows of teeth to make sure

that the profile of the cut is smooth and square.

The machine has all kinds of adjustments on it. Aside from the plunge motion,

the cutter head can be moved forward and back, and side-to-side.

The in/out and side to side motions can be locked, or slid back and forth against limit stops.

That way, multiple plunge cuts can be made to make mortises

larger than the chain can do with one plunge.

The machine has all kinds of adjustments on it. Aside from the plunge motion,

the cutter head can be moved forward and back, and side-to-side.

The in/out and side to side motions can be locked, or slid back and forth against limit stops.

That way, multiple plunge cuts can be made to make mortises

larger than the chain can do with one plunge.

The most intriguing adjustment was the knob towards the bottom center of this photo. Pulling the knob up allows the attached piece of steel to rotate, by a quarter turn in each direction. This in turn causes the whole upper assembly of the mortiser to tilt to the left and right by a few degrees. At first I was puzzled why one would bother to tilt the head by a fixed few degrees - it's not really much of an adjustment. But Kurt explained that the purpose for this was to make "under cut" mortises. Basically, the idea is to make two plunge cuts, tilted in either direction. This results in a mortise that is wider at the bottom than at the top. That sort of mortise is useful when making wedged mortise and tenon joints. With the strength of modern glues, wedging a tenon joint doesn't actually add any strength anymore. But I imagine that when this machine was built, wedged tenon joints were perhaps still more of a traditional thing to use.

A side view of the chain mortiser. Towards the bottom, you can see the mechanism for moving

the cutter head side to side via a lever extending out of the right of the photograph.

A side view of the chain mortiser. Towards the bottom, you can see the mechanism for moving

the cutter head side to side via a lever extending out of the right of the photograph.

There is another really big lever on the top of the machine, which I unfortunately didn't get in any of my photographs. That lever is used for plunging the cutter head into the wood.

Another interesting aspect that this shot reveals is how the motor housing is an integral part of the casting of the head assembly. Nowadays, the whole motor would be bought from another company.

I cut a small mortise in a test piece to see how clean it would cut. I then

cut the test piece apart with a band saw to have a better look inside.

I cut a small mortise in a test piece to see how clean it would cut. I then

cut the test piece apart with a band saw to have a better look inside.

The bottom of the mortise is rather round-ish, so for mortises that are not through mortises, the edges of the tenons need to be cut round with a band saw. That or chiseling out the mortise to make it square.

For mortises cut with more than one plunge, the bottom of the mortise would be flat, with just the corners round. I would imagine a mortise that size would normally be cut as multiple plunges with a smaller chain.

See also: Home made slot mortiser