I often cut a dado by making a series of cuts on the table saw. But getting

the width exactly right can be tricky.

I often cut a dado by making a series of cuts on the table saw. But getting

the width exactly right can be tricky.

I often cut a dado by making a series of cuts on the table saw. But getting

the width exactly right can be tricky.

I often cut a dado by making a series of cuts on the table saw. But getting

the width exactly right can be tricky.

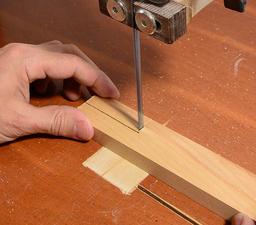

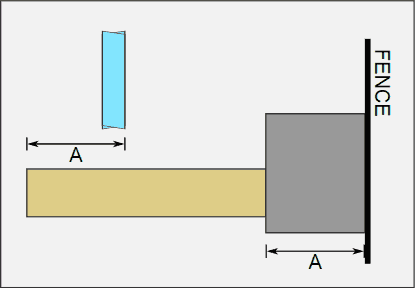

It would be cool if I could just use a stop block, make a cut, then use the piece that fits in the dado as a spacer to position the cut on the other end of the dado. But doing so would result in a dado that is one blade thickness wider than it should be.

So the thing to do would be to make a spacer from the wood that needs to

fit in the dado and cut exactly one blade width off the edge.

Lining it up so the blade cuts exactly its width off the edge would be tricky,

but it's quite easy to cut one blade width out of the middle of the piece.

So the thing to do would be to make a spacer from the wood that needs to

fit in the dado and cut exactly one blade width off the edge.

Lining it up so the blade cuts exactly its width off the edge would be tricky,

but it's quite easy to cut one blade width out of the middle of the piece.

So that's what I did, then stuck the two pieces back together with some glue stick.

I used glue stick because I don't have to wait for it to dry, it doesn't add thickness,

and it doesn't need to be strong.

So that's what I did, then stuck the two pieces back together with some glue stick.

I used glue stick because I don't have to wait for it to dry, it doesn't add thickness,

and it doesn't need to be strong.

Now that I have a spacer that is exactly one blade width thinner than the dado I need,

I start by making a cut with the spacer piece between the workpiece and the stop block.

Now that I have a spacer that is exactly one blade width thinner than the dado I need,

I start by making a cut with the spacer piece between the workpiece and the stop block.

I then make another cut with the spacer removed and the workpiece against the stop

block, and then a series of cuts to remove the material in between.

I then make another cut with the spacer removed and the workpiece against the stop

block, and then a series of cuts to remove the material in between.

I should add, blade vibrations can make the kerf slightly wider at times, and cutting through wood can stabilize the blade or add further vibrations. Which is to say, your blade, especially a cheap one on a cheap saw, will not always cut the same width. This can make for a less than perfect fit.

I should also mention the expensive Bridge City Toolworks kerfmaker by Bridge City Tool Works. Why mention it? Just so you know I know about it. No need to email me about it.

I filmed my video on May 18 2015, but as I often do, decided to save it for a bit before

publishing it. But then, on May 26, Dominic Bender published the video about

a very similar method.

Not wanting to look like a copy cat, I finished the editing on my video and uploaded

it within three hours of his.

On seeing my video on the dado spacer, Ketil Skjerve, from Norway wrote:

Hello Matthias,

I just saw your video on how to cut a spacer that is the dado width minus one blade thickness. What a great idea!

But sometimes, the piece that goes into the dado can't be cut into two, maybe because you only have that one piece you are going to use, or maybe it isn't made from wood. So I started thinking on how to make a copy of the piece using a scrap piece of wood, and then cut the copy in halves.

I realized that my approach would result in the copy not being of the same width, but one saw blade width narrower. That is however what you want in the first place!

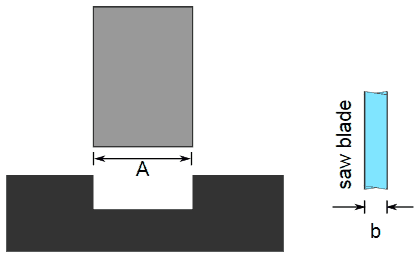

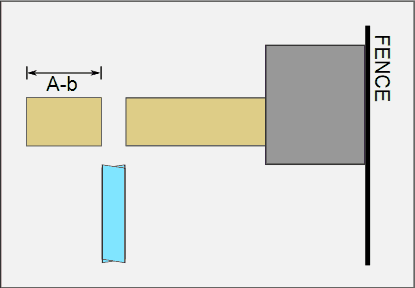

Let's say you want a spacer for cutting a dado of width A, using a blade that is b thick.

Let's say you want a spacer for cutting a dado of width A, using a blade that is b thick.

The spacer then needs to be A-b thick. You only need a scrap piece of wood.

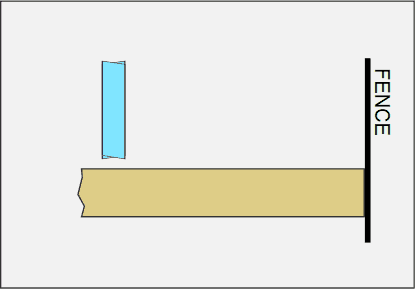

First you set up your fence or stop block and align the scrap piece against it:

First you set up your fence or stop block and align the scrap piece against it:

Then make a cut:

Then make a cut:

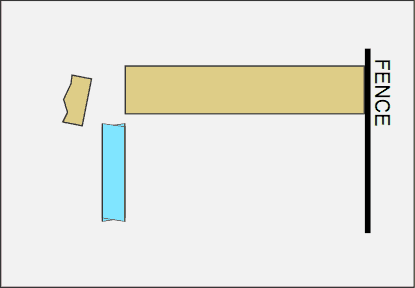

Without moving the fence, place the piece that goes into the dado between the scrap piece and the fence, and make a new cut:

Without moving the fence, place the piece that goes into the dado between the scrap piece and the fence, and make a new cut:

The resulting piece will be of length A-b, exactly what you want!

The resulting piece will be of length A-b, exactly what you want!

You can shim the first or second cut to get a tighter or looser fit.

I'm sure you or someone else has thought of this already, but I can't recall seeing it being done. Maybe you can make a video of this method as well?

Bottom line: no need to buy a Kerfmaker tool, when it is so fast and simple to make an exact spacer from scraps!

Best regards,

Ketil Skjerve

Norway

PS: I bought your Pantorouter XL plans before Christmas, and I have finally started building it! Looking good so far!

More Wood shop tricks