Contractor saw vibration damper

The way I have the motor mounted on my old table saw, if I crank the blade most of the way

down, the motor mount "bottoms out" so the motor is no longer hanging off the belt.

I noticed that in this state, there is a lot less vibration.

The way I have the motor mounted on my old table saw, if I crank the blade most of the way

down, the motor mount "bottoms out" so the motor is no longer hanging off the belt.

I noticed that in this state, there is a lot less vibration.

I thought it was because, with the motor mount bottomed out, the motor can't move up and down with the belt anymore. This gave me the idea of mounting a shock absorber between the motor and its mount to prevent it from shaking up and down.

So I bought some bicycle shock absorbers online, not for the spring, but for the

shock absorber part. But once I removed the spring , I realized

the "shock absorber" part had nothing in it!

So I bought some bicycle shock absorbers online, not for the spring, but for the

shock absorber part. But once I removed the spring , I realized

the "shock absorber" part had nothing in it!

I had seen some very old cars with friction shock absorbers, so I had the

idea of making a sort of friction dampener instead.

But to get more room for that, I figured I'd make it go from the motor mount down

to the bottom of the stand. To accommodate depth and tilt adjustments, I needed

a ball and socket joint for each end.

I had seen some very old cars with friction shock absorbers, so I had the

idea of making a sort of friction dampener instead.

But to get more room for that, I figured I'd make it go from the motor mount down

to the bottom of the stand. To accommodate depth and tilt adjustments, I needed

a ball and socket joint for each end.

I experimented with carving out a hemisphere, mostly on the belt sander, and drilled an undersized hole, chamfered the edges of it, and tried it out. Though not a captive joint, it worked well enough.

I needed another ball and socket for the bottom. I cut the corners off a piece of

wood, then shaped it by spinning it in a drill against a belt sander.

This worked well enough without having to worry about how to chuck the piece up

on the lathe.

I needed another ball and socket for the bottom. I cut the corners off a piece of

wood, then shaped it by spinning it in a drill against a belt sander.

This worked well enough without having to worry about how to chuck the piece up

on the lathe.

I drove the peg into a hole in a piece of hardwood

I drove the peg into a hole in a piece of hardwood

This piece mounts to the legs of the table saw. I started out by attaching it

with some C-clamps.

This piece mounts to the legs of the table saw. I started out by attaching it

with some C-clamps.

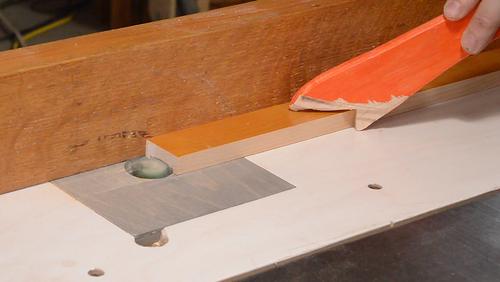

My friction shock absorber consists of two C-shaped rails. I shaped these by

cutting a slot in them with the router.

My friction shock absorber consists of two C-shaped rails. I shaped these by

cutting a slot in them with the router.

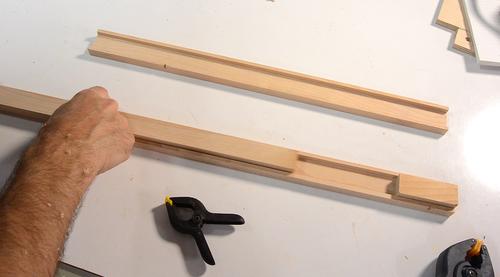

A rectangular piece of wood slides between the two C-channels.

A rectangular piece of wood slides between the two C-channels.

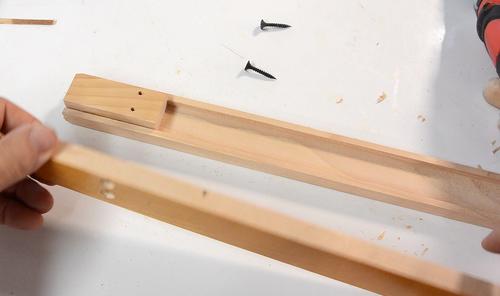

A block of wood is glued into one end of one of the C-channels,

and the other C-channel screws to that block of wood.

A block of wood is glued into one end of one of the C-channels,

and the other C-channel screws to that block of wood.

I drilled some large holes into the ends of my friction damper and chamfered the edges to act as the socket part of the ball and socket joints.

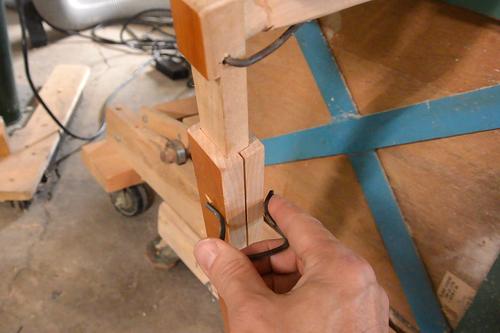

Testing how the damper telescopes.

Testing how the damper telescopes.

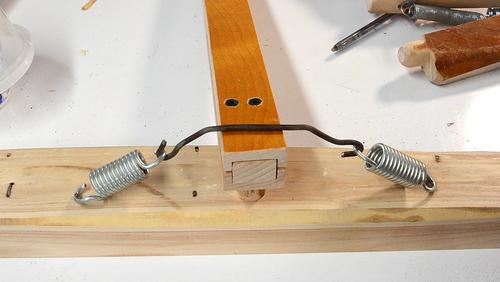

With the shallow (not captive) ball and socket joint, I need springs to press

the joints together, so for one end, I drilled a hole near either side of

the socket and made a wire "clip" to hook a spring onto.

With the shallow (not captive) ball and socket joint, I need springs to press

the joints together, so for one end, I drilled a hole near either side of

the socket and made a wire "clip" to hook a spring onto.

With the wire clip extending beyond the ball and socket, it helps to

stabilize the joint. If the spring was hooked directly to the

link, the socket would have a tendency to slide off the side of the ball.

With the wire clip extending beyond the ball and socket, it helps to

stabilize the joint. If the spring was hooked directly to the

link, the socket would have a tendency to slide off the side of the ball.

On the bottom end, I didn't have room for a clip like the top end, so I made

a wire that goes over the socket part of the joint. Again, this wire

discourages the socket from sliding off the ball.

On the bottom end, I didn't have room for a clip like the top end, so I made

a wire that goes over the socket part of the joint. Again, this wire

discourages the socket from sliding off the ball.

Then testing it out, subjectively judging the vibrations by looking

at the waves in a small container of water. When I put a small spring

clamp on the damper to give it some friction, it made no noticeable

difference to the waves in the container. Under some circumstances,

it even made it worse!

Then testing it out, subjectively judging the vibrations by looking

at the waves in a small container of water. When I put a small spring

clamp on the damper to give it some friction, it made no noticeable

difference to the waves in the container. Under some circumstances,

it even made it worse!

I figured maybe the reason the vibrations went down when the motor mount

bottomed out was because of reduced belt tension. I experimented with using

a spring to help pull up the motor to reduce belt tension. This helped,

but not hugely so. I experimented with how much belt tension I actually needed

and realized that even without the spring, the belt would slip before the

motor stalled under heavy load. So I really shouldn't be reducing belt tension.

I figured maybe the reason the vibrations went down when the motor mount

bottomed out was because of reduced belt tension. I experimented with using

a spring to help pull up the motor to reduce belt tension. This helped,

but not hugely so. I experimented with how much belt tension I actually needed

and realized that even without the spring, the belt would slip before the

motor stalled under heavy load. So I really shouldn't be reducing belt tension.

Turning the blade slowly and watching the motor, I could see it moving up and

down by at least 1 mm (0.040"). This seemed a bit much.

Turning the blade slowly and watching the motor, I could see it moving up and

down by at least 1 mm (0.040"). This seemed a bit much.

I tried a different V-belt, and this one produced only about 0.010" of movement. Running it with that V-belt, I got much less vibration.

Comparing the two V-belts. You can see the one on the right has a bit of damage,

so you would expect that to result in some vibration. Except, that's the one

that causes less vibration. The one on the left causes much more vibration,

with no visible signs of damage!

Comparing the two V-belts. You can see the one on the right has a bit of damage,

so you would expect that to result in some vibration. Except, that's the one

that causes less vibration. The one on the left causes much more vibration,

with no visible signs of damage!

I tried holding a weight against the motor, and that seemed to help a bit.

So I decided to mount that to the bottom of the motor mount to help

stabilize it and get some of the belt tension back. More weight should reduce

vibrations, and the spring helps counter the extra belt tension the weight would add.

I tried holding a weight against the motor, and that seemed to help a bit.

So I decided to mount that to the bottom of the motor mount to help

stabilize it and get some of the belt tension back. More weight should reduce

vibrations, and the spring helps counter the extra belt tension the weight would add.

Bolting the weight to the bottom of the motor mount. The weight helped, but again,

it only made a relatively small difference.

Bolting the weight to the bottom of the motor mount. The weight helped, but again,

it only made a relatively small difference.

Though I previusly gave up up on the friction dampener, on a whim, I tried it again.

And this time it worked really well. I guess it just didn't work on the kind of

vibrations I got from the other V-belt. So I took the spring and the weight back off

the saw.

Though I previusly gave up up on the friction dampener, on a whim, I tried it again.

And this time it worked really well. I guess it just didn't work on the kind of

vibrations I got from the other V-belt. So I took the spring and the weight back off

the saw.

I made a spring clip to act as a clamp (as opposed to leaving a spring clamp on there)

I then tested the full range of tilt and depth adjustments to make sure the friction

damper would not impede the motion. Though, at 45°, the angle is not optimal,

and I don't expect it to help much with the saw tilted like that.

I then tested the full range of tilt and depth adjustments to make sure the friction

damper would not impede the motion. Though, at 45°, the angle is not optimal,

and I don't expect it to help much with the saw tilted like that.

But overall, vibrations are much reduced. No more pieces of scrap wood wandering

along the table saw while it's running. And I can balance a coin on any part of

of the table while it's running.

But overall, vibrations are much reduced. No more pieces of scrap wood wandering

along the table saw while it's running. And I can balance a coin on any part of

of the table while it's running.

See also:

Back to my Woodworking website.

More about this

More about this Are link belts worth it?

Are link belts worth it? Bandsaw vibrations

Bandsaw vibrations What's a hybrid table saw?

What's a hybrid table saw? Table saw mobile base

Table saw mobile base Homemade table saw

Homemade table saw Multi-modal vibrations: A bell that rings two notes

Multi-modal vibrations: A bell that rings two notes