After making some of the tool holders for

my big garage workshop, I still had

a lot of empty space on the plywood and various tools I wanted

within easy reach.

After making some of the tool holders for

my big garage workshop, I still had

a lot of empty space on the plywood and various tools I wanted

within easy reach.

After making some of the tool holders for

my big garage workshop, I still had

a lot of empty space on the plywood and various tools I wanted

within easy reach.

After making some of the tool holders for

my big garage workshop, I still had

a lot of empty space on the plywood and various tools I wanted

within easy reach.

I made a sort of shelf for my hammers, marking gauge and squares. Some of these

hang through the shelf. Here, I'm marking where I need to cut notches for

the mallet and marking gauge.

I made a sort of shelf for my hammers, marking gauge and squares. Some of these

hang through the shelf. Here, I'm marking where I need to cut notches for

the mallet and marking gauge.

I then cut these out on a bandsaw, and glued it to another board that will attach to the wall.

Arranging the tools. I punched divots where I needed to put screws.

I pre-drilled all the screw holes; with hardwood, you need to.

Arranging the tools. I punched divots where I needed to put screws.

I pre-drilled all the screw holes; with hardwood, you need to.

My claw hammer is held by two dowels.

My claw hammer is held by two dowels.

Another dowel helps hold the squares straight so they won't hang crooked.

It's happened with my other tool holders

that, banging away at things on the workbench, eventually the mallet

or the marking gauge slies off the tool holders from vibrations.

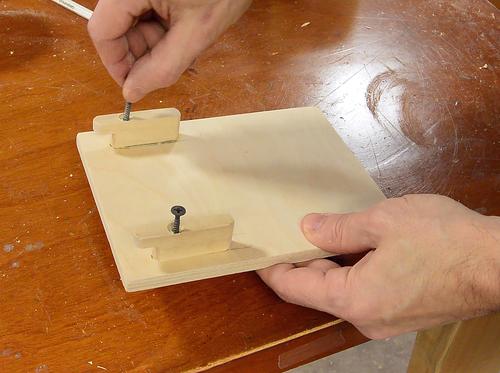

So I drilled two shallow holes in the bottom of the mallet,

and put two sheet metal screws in the shelf to interlock it.

It's happened with my other tool holders

that, banging away at things on the workbench, eventually the mallet

or the marking gauge slies off the tool holders from vibrations.

So I drilled two shallow holes in the bottom of the mallet,

and put two sheet metal screws in the shelf to interlock it.

A small ridge in front of the marking gauge keeps it from sliding off also.

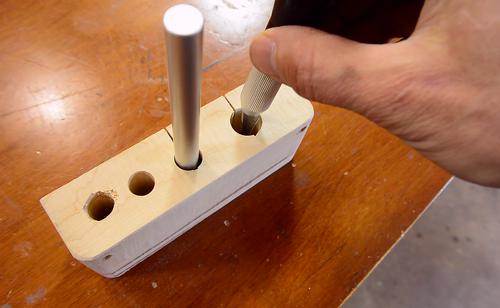

I figured the empty spot on the top right of this shelf would be perfect for

my dial indicator. I made a small block with a hole in it to

keep it from tipping off. The post of the dial indicator fits into it.

To remove it, I have to slide it out from under.

I figured the empty spot on the top right of this shelf would be perfect for

my dial indicator. I made a small block with a hole in it to

keep it from tipping off. The post of the dial indicator fits into it.

To remove it, I have to slide it out from under.

Here marking the outline of the sides of one of my hand planes

to make a holder for it.

Here marking the outline of the sides of one of my hand planes

to make a holder for it.

To cut the angled part of the profile, I made a spacer block to hold the workpiece

on the saw at an angle.

Here, holding a strip of wood between the workpiece and the fence. It's just

the right width from the fence, so I need to set the fence to that.

To cut the angled part of the profile, I made a spacer block to hold the workpiece

on the saw at an angle.

Here, holding a strip of wood between the workpiece and the fence. It's just

the right width from the fence, so I need to set the fence to that.

This is really hard to explain with pictures. To get a better understanding, watch the video.

Then with the spacer behind the workpiece. I'm making an angled cut,

then another cut with the workpiece against the fence and the spacer under

it to finish the cut.

Then with the spacer behind the workpiece. I'm making an angled cut,

then another cut with the workpiece against the fence and the spacer under

it to finish the cut.

I finished the curve by carving it with a chisel.

I finished the curve by carving it with a chisel.

I then draw a line about 6 mm from the edge, and cut that with a bandsaw. Also, cutting some curves and corners on the ends to style it a bit nicer.

I used the same method to make a holder for a smaller hand plane as well.

I used the same method to make a holder for a smaller hand plane as well.

The plane fits in the holder like a wedge, which can make the

plane hard to pull out. To prevent it from wedging in, I'm adding two

screws to the bottom of the holder to act as a stop, before it gets tight.

The plane fits in the holder like a wedge, which can make the

plane hard to pull out. To prevent it from wedging in, I'm adding two

screws to the bottom of the holder to act as a stop, before it gets tight.

The drill press vise is held by a piece of plywood with two hooks on it.

The hooks are cut out on the bandsaw.

The drill press vise is held by a piece of plywood with two hooks on it.

The hooks are cut out on the bandsaw.

The mounting screws go straight through the hooks. It's the hooks that have

to hold the heavy vise, so I might as well reinforce them with the screw.

The mounting screws go straight through the hooks. It's the hooks that have

to hold the heavy vise, so I might as well reinforce them with the screw.

Here, making a board with roofing nails on it to hold the crescent wrenches.

Here, making a board with roofing nails on it to hold the crescent wrenches.

I guess I could have put the nails straight in the plywood, but this looks

nicer, and the wrenches are easier to grab. I'm only hanging the stubby

ones. If I need more torque, I have the full sized ones in a drawer.

I guess I could have put the nails straight in the plywood, but this looks

nicer, and the wrenches are easier to grab. I'm only hanging the stubby

ones. If I need more torque, I have the full sized ones in a drawer.

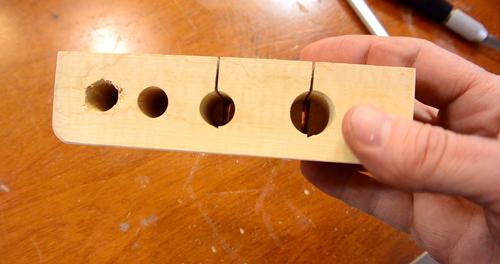

Another tool holder to hold some knives. First some holes drilled

to hold the handle, then a slot, cut with the bandsaw, for the blade.

Another tool holder to hold some knives. First some holes drilled

to hold the handle, then a slot, cut with the bandsaw, for the blade.

I just have to make sure the knife is in the right orientation when I put it in.

I just have to make sure the knife is in the right orientation when I put it in.

And a shelf made for my tape measures. I didn't take any pictures of

making this one - it's made a lot like the other ones.

And a shelf made for my tape measures. I didn't take any pictures of

making this one - it's made a lot like the other ones.

Tape measures ready at hand, and some of the other tools already slightly

rearranged.

Tape measures ready at hand, and some of the other tools already slightly

rearranged.

I end up moving the tool holders from time to time, which leaves small screw holes. A french cleat system would make it easier to move stuff, but is much less flexible, and I find the few extra screw holes still less ugly than a french cleat system, and a lot less work.