The next thing my bandsaw needed was a motor. I decided to try to

recycle this pool pump motor that I picked out of the garbage.

The next thing my bandsaw needed was a motor. I decided to try to

recycle this pool pump motor that I picked out of the garbage.

The next thing my bandsaw needed was a motor. I decided to try to

recycle this pool pump motor that I picked out of the garbage.

The next thing my bandsaw needed was a motor. I decided to try to

recycle this pool pump motor that I picked out of the garbage.

It's a 1 HP motor, and fairly light. I want this bandsaw to be fairly powerful and

easy to move, so in this regard, the motor is ideal.

It's a 1 HP motor, and fairly light. I want this bandsaw to be fairly powerful and

easy to move, so in this regard, the motor is ideal.

Less ideal is that it's a 3450 RPM motor (instead of 1750), so I need quite a bit of reduction. It also turned in the wrong direction and the label indicates that it's "non reversible". But reversing AC motors is just a matter of reversing the polarity of the starter winding (which is in series with the centrifugal switch). I was able to reverse this one by bringing a separate wire out from the windigns to the switch.

I was aiming for a blade speed around 1500 FPM, or about 7.5 m/s. With a 14" lower wheel,

that means the lower wheel should run at 409 RPM. So I'd need about an 8.4:1 reduction.

Even if I make the lower pulley 12" (30 cm) in diameter, I'd need a 1.5" V-belt pulley

to get about the right speed.

I was aiming for a blade speed around 1500 FPM, or about 7.5 m/s. With a 14" lower wheel,

that means the lower wheel should run at 409 RPM. So I'd need about an 8.4:1 reduction.

Even if I make the lower pulley 12" (30 cm) in diameter, I'd need a 1.5" V-belt pulley

to get about the right speed.

The problem with small V-belt pulleys is that they are inefficient. The belt has to bend tightly around the pulley, and it also gets wedged into the groove. All that bending, unbending, wedging, and un-wedging uses up a fair bit of energy. The wedging and bending is less of a problem for larger V-belt pulleys. If I had a 1750 RPM motor, I'd use a 3" pulley, and wouldn't worry about it.

Because part of my goal with this bandsaw is experimentation, I decided to try using a flat belt instead of a V-belt.

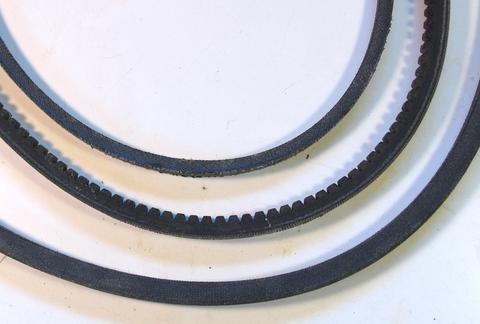

Most bearing stores can custom order belts, but for now I'm using an old

timing belt from a Honda Civic. Flipped inside out, it can be used as a flat belt.

Most bearing stores can custom order belts, but for now I'm using an old

timing belt from a Honda Civic. Flipped inside out, it can be used as a flat belt.

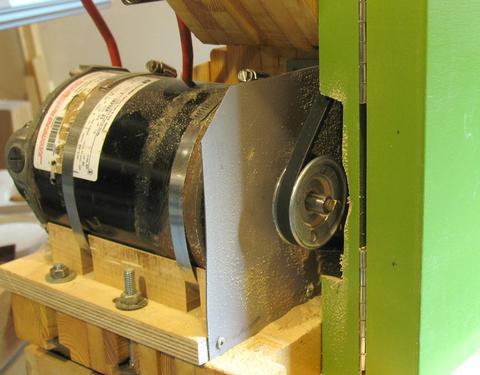

Another problem with this motor was that it had no mounting bracket.

So I made two triangular rails to go on either side of the

motor. These rails actually have a concave "cover cut" on the sides facing the

motor to match it's curvature. Some 6" hose clamps around the rails and the motor

hold it in place.

Another problem with this motor was that it had no mounting bracket.

So I made two triangular rails to go on either side of the

motor. These rails actually have a concave "cover cut" on the sides facing the

motor to match it's curvature. Some 6" hose clamps around the rails and the motor

hold it in place.

For my Initial experiments I used just a small disk of wood rammed onto the shaft,

and trying to track the belt on one of the rims of the temporary V-belt pulley

that I used when turning the wheels.

For my Initial experiments I used just a small disk of wood rammed onto the shaft,

and trying to track the belt on one of the rims of the temporary V-belt pulley

that I used when turning the wheels.

I couldn't get the belt to track, but I learned a bit. If it mis-tracked against the tire of the lower wheel, it would start to chew into that and pull it out of place. Not good!

Also, if a flat belt slips at all, it really likes to come off the pulleys!

So I glued several pieces of plywood together and rammed that onto the motor.

So I glued several pieces of plywood together and rammed that onto the motor.

I then used a chisel to turn that to a pulley shape.

I left flanges on either side of the pulley so that the belt wouldn't keep

coming off if it didn't track perfectly. The idea is to rely on

crowned pulleys tracking the flat belt

I left flanges on either side of the pulley so that the belt wouldn't keep

coming off if it didn't track perfectly. The idea is to rely on

crowned pulleys tracking the flat belt

I made a large ring-shaped pulley to attach to the wheel. This is only screwed in

place. I wasn't sure if the whole flat-belt thing was going to work, so if I wasn't

successful, I could just replace it with a V-belt pulley later.

I made a large ring-shaped pulley to attach to the wheel. This is only screwed in

place. I wasn't sure if the whole flat-belt thing was going to work, so if I wasn't

successful, I could just replace it with a V-belt pulley later.

Shaping the larger pulley using my usual lathe technique.

I'm using the same temporary pulley that I used

for shaping the crown of the wheels to spin the wheel.

Shaping the larger pulley using my usual lathe technique.

I'm using the same temporary pulley that I used

for shaping the crown of the wheels to spin the wheel.

Here's the shape of my pulley. Maybe a bit much of a crown on it. Also note the flange

on the wheel side of the pulley. If the belt starts to come off in that

direction, it will rub against the flange instead of the tire.

Here's the shape of my pulley. Maybe a bit much of a crown on it. Also note the flange

on the wheel side of the pulley. If the belt starts to come off in that

direction, it will rub against the flange instead of the tire.

And here it is attached to the bandsaw. Alignment is very critical for flat belts, and it

took a bit of tweaking to get it to track. I inserted a wedge under the back of the motor

in this photo. I'll worry about bolting it to the frame once the rest of the

bandsaw is further along.

And here it is attached to the bandsaw. Alignment is very critical for flat belts, and it

took a bit of tweaking to get it to track. I inserted a wedge under the back of the motor

in this photo. I'll worry about bolting it to the frame once the rest of the

bandsaw is further along.

Having done a fair bit of experimenting with the saw since, the flat belt seems to be working out acceptably well. I deliberately stalled the saw one time, and the belt started to slip on the motor pulley. The belt and motor started to smoke pretty much instantly, though I stopped it before either was ruined.

When a flat belt starts slipping, it usually also starts to come off the pulley. On some applications, having the belt come off when something is stalled could be a useful safety feature. Unfortunately, with the pulley flanges, and general lack of room around the pulley, I can't take advantage of this here. I'll just have to make sure I have enough tension on the belt so that the motor will stall before the belt slips.

What convinced me to switch to a V-belt was when I was examinging some of the belts I had

around, and one of the V-belts was more flexible, with teeth on the inside. It also happened

to be just about the right length, so I didn't have to buy one.

What convinced me to switch to a V-belt was when I was examinging some of the belts I had

around, and one of the V-belts was more flexible, with teeth on the inside. It also happened

to be just about the right length, so I didn't have to buy one.

I was also getting worried that with the excessive tension I had to put on the flat belt, that I might damage the motor bearings, or, worse yet, cause metal fatigue in the thin 1/2" motor shaft.

I also decided to run the bandsaw a bit faster, so I'd be using about a

2.5" V-belt pulley, which doesn't require the belt to turn a very tight radius.

I also decided to run the bandsaw a bit faster, so I'd be using about a

2.5" V-belt pulley, which doesn't require the belt to turn a very tight radius.

So I removed the flat belt pulley from the wheel and proceeded to turn a V-belt pulley.

The V-velt I had was just about the right length, so I just sized the larger pulley to

make it work. I needed about a 21.5 to 22 cm pulley spacing. Here's checking the spacing

with the belt on the pulley. Basically, I kept turning the groove deeper until I got

just the right distance with the 2.5" pulley.

The V-velt I had was just about the right length, so I just sized the larger pulley to

make it work. I needed about a 21.5 to 22 cm pulley spacing. Here's checking the spacing

with the belt on the pulley. Basically, I kept turning the groove deeper until I got

just the right distance with the 2.5" pulley.

And here's the motor with the new V-belt pulley.

And here's the motor with the new V-belt pulley.

I haven't entirely given up on the idea of a flat belt, but for this application, a flat belt turned out to be a bad idea.

I also installed a piece of sheet metal between the motor and the pulley. The motor is an open framed motor that pulls air in from the front, and the sheet metal ensures that the motor doesn't suck in the dusty air from inside the enclosure. There is a gap between the sheet metal and the motor to allow the motor to still pull air in from the front.

Next: Bandsaw table