Paul's dowel maker

Paul's dowel maker Paul's homemade bandsaw

Paul's homemade bandsawPaul writes:

There is nothing to do in the garden in winter, so I have time to tinker. I only worked on one marble machine at a time, and when I had another idea, I continued building, without hurry and only when I felt like it. When I finished, I looked for new ideas and inspirations on the internet. I usually "plan" directly with wood, no drawings. Of course, that results in a lot of scrap, which goes in the fireplace. The wood I use is mostly firewood from a local factory. Ash, some maple, and some linden. I make the dowels myself, similar to the method on your page. I learned that from my father. The knife is made from an old hacksaw blade.

Paul

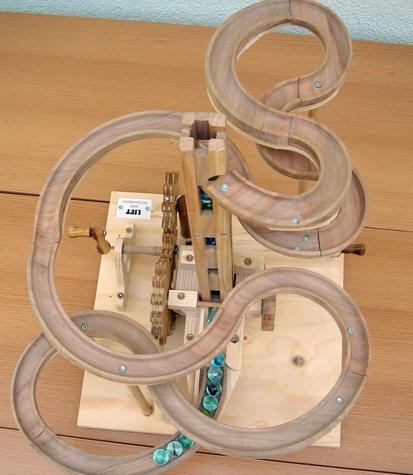

This was my first try. I used a lot of ideas from you

(Marble machine 2).

I was very happy when I had it complete and working.

This was my first try. I used a lot of ideas from you

(Marble machine 2).

I was very happy when I had it complete and working.

This machine has since inspired Ryszard Grenda

to build his own version:

Chaos2

The marble pump with piston and crankshaft is also

copied from you

(marble machine 1).

The track was turned on the lathe and then cut and assembled into a track.

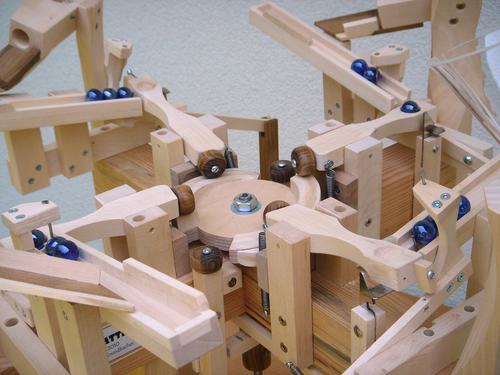

The flip-flop from your marble machines inspired me to build this machine. The marble often bounced out of the machine, so I added "catch nets" made of dowels. I saw the wooden roller chain in a video by Michael Schultheiss. It was a lot of work to make this chain, but it runs without problems.

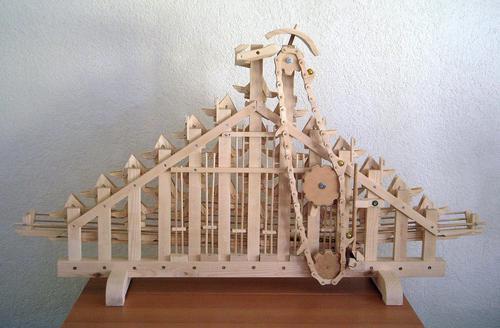

I found the plans on the internet. Many hobby woodworkers build

such ladders, powered by cams. It reminded me of a fish ladder in rivers,

so I added a waterweel. The marbles enter the wheel from the side to

avoid the possibility of jamming between the wheel and the ramp.

I found the plans on the internet. Many hobby woodworkers build

such ladders, powered by cams. It reminded me of a fish ladder in rivers,

so I added a waterweel. The marbles enter the wheel from the side to

avoid the possibility of jamming between the wheel and the ramp.

I copied this idea from Brad Litwin's Quadrapult. I hope he doesn't assert any copyrights :)) I watched his video many times, took screen captures and studied the mechanism. Brad's Quadrapult is powered by a motor, so the marbles arrive at the catapult at regular intervals. Because I wanted to build mine hand-cranked, I could not count on the marbles arriving consistently. The marble delivery with marble magazine made for a lot of work.

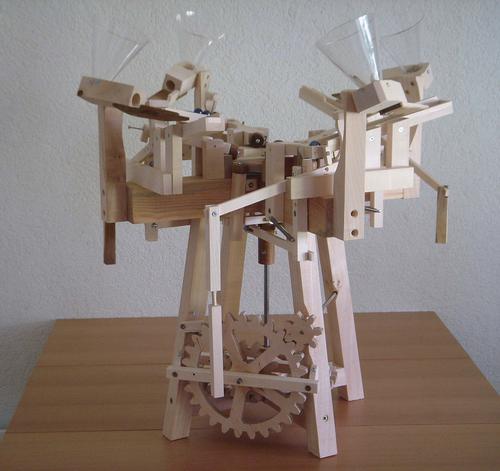

Here too, I was inspired by a video: "the ball lifter" by YouTube user denha. I watched it many times, then built mine similar.

I started with five square posts attached to four glued wooden rings.

For a whole year, it served just as a coat tree in my small workshop.

Without drawings, I added part after part without knowing how

the finished machine would look.

I didn't need any instructions from the internet for this machine.

I worked on it on-and-off for three winters before it was complete.

Finally, I needed to add a speed regulator,

(similar to steam engines) because at higher speeds the

lift chain would not properly throw all the marbles into the funnel at the top.

I started with five square posts attached to four glued wooden rings.

For a whole year, it served just as a coat tree in my small workshop.

Without drawings, I added part after part without knowing how

the finished machine would look.

I didn't need any instructions from the internet for this machine.

I worked on it on-and-off for three winters before it was complete.

Finally, I needed to add a speed regulator,

(similar to steam engines) because at higher speeds the

lift chain would not properly throw all the marbles into the funnel at the top.

More about the Archimedis machine:

A shallow bowl sits at the bottom of the frame made of five vertical members. The transport chain scoops up the marbles from the bowl with its small wooden cups and brings them all the way to the top. At the top, the marbles roll out by gravity and fall into the funnel. Proper ejection of the marbles is very sensitive to speed. Low speeds are ok, but at high speeds, many marbles miss the funnel and fall out randomly.

A "tube" made of dowels guides the marbles down to the upper Archimedes screw. Proper entry into the screw is problematic, so I made a guard out of dowels at the entrance. The wooden Archimedes screw raises the marbles. At the top they fall onto a slanted board with a "fence" on either side. They roll down, fall into a funnel, and roll onto a half-round track, fall again into a funnel, and find their way to two "water wheels", which they turn. They fall down to a board below, making loud clacking sounds as they roll to the lower bowl. Just before reaching the bowl, half the marbles are diverted with a flip-flop to the lower Archimedes screw. This screw brings the marbles half way to the top and dumps them in a bowl. After passing through a funnel, they fall onto a track, roll several times around the tower, and find their way to the large bowl at the bottom. Without the flip-flop, the Archimedes screw would have difficulty transporting all the marbles.

The main drive shaft is in the middle of the tower, with a crank on either side. All turning parts are powered from this shaft via gears and bevel gears. There is also a ratchet, because turning the machine backwards, even briefly, can cause marbles to fall out. To prevent the machine from getting turned too fast, the main drive shaft also powers a governor-brake.

Height: 150 cm

Weight: 17.5 kg

Materials: Ash, some Maple, Linden, Cherry, Pear and Beech

Gears are made from plywood, 12 mm, designed with the gear template generator

and cut with the bandsaw and fine tuned with a file.

8 mm steel shafts for the axles. Ball bearings from inline skates.

Also wood screws and wood glue. No varnish.

This machine has inspired Ryszard Grenda to build his own version: Archimedis

Marble run building blocks (version 1)

Marble run building blocks (version 1) Marble run building blocks (version 2)

Marble run building blocks (version 2) Michael Schultheiss's

marble machine

Michael Schultheiss's

marble machine Ron Walter's

marble machine

Ron Walter's

marble machine Ryszard's Archimedis marble machine

Ryszard's Archimedis marble machine Richard's "Chaos2" marble machine

Richard's "Chaos2" marble machineBack to the main woodworking website.