Alois Schmid's table saw laser sight

This article contributed by Alois Schmid. Translated from German by Matthias

The idea was to build a line laser, as is available for many format style

table saws, but for much less money.

The idea was to build a line laser, as is available for many format style

table saws, but for much less money.

I found a line laser for 5€, but this laser only projected a narrow beam and would have to be mounted at a low angle over the work to produce a long enough line.

The problem was how to mount it. To get a decent line, the laser would

have to be mounted directly on the machine. This would make

a non-through cut impossible without removing the laser every time.

The problem was how to mount it. To get a decent line, the laser would

have to be mounted directly on the machine. This would make

a non-through cut impossible without removing the laser every time.

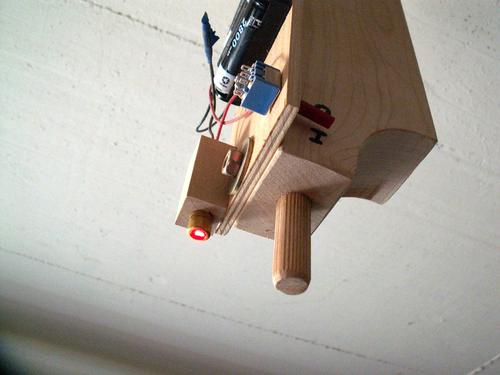

This gave me the idea to mount the laser on the ceiling, this time

using a different laser from Laserfuchs for 17.55€. This laser

is focused for two meters away.

This gave me the idea to mount the laser on the ceiling, this time

using a different laser from Laserfuchs for 17.55€. This laser

is focused for two meters away.

https://secure.picotronic.de/laserfuchs/index.php/cPath/15/category/Linien-Laser-rot

Building the mount was easy. I only used what I already had

in my workshop

Building the mount was easy. I only used what I already had

in my workshop

The laser gets a little out of focus towards the ends of the line that

it projects, but that doesn't bother me much.

The laser gets a little out of focus towards the ends of the line that

it projects, but that doesn't bother me much.

|

If I don't use the laser for a while, the alignment is often

a little off, because of wood shrinkage and expansion from humidity changes

|

|

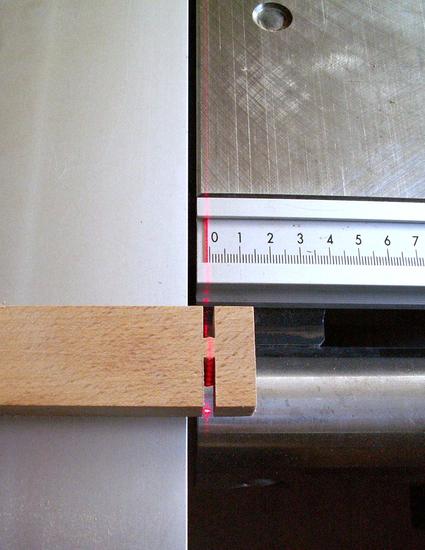

I built this simple jig to help align the laser. |

The mount adjusts by loosening the wing nuts

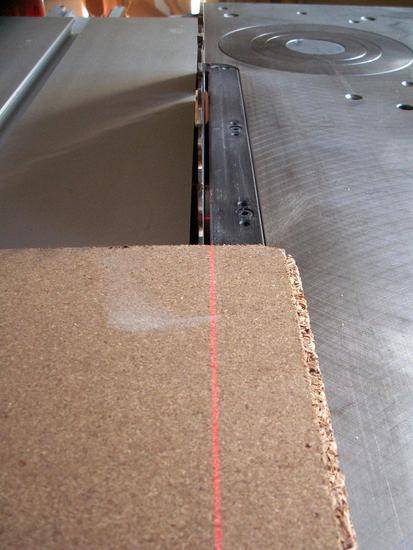

Using the laser to cut the rough edge off a piece of particle board.

I mostly use the laser for the first cut, to remove the bark edge from a rough board.

Matthias comments:

In Germany, lumber for furniture is often bought rough, with the bark edge still on. To trim the bark edge off, the board is placed on the sled of a format style table saw and a cut is made. Many format style table saws, including Alois's, have sleds over 2 meters in length. For another example, see here.

See also: