So I had the idea for making a really long sort of "deadbolt". I needed

a means of transferring rotating motion from a handle to the linear

motion of the latch. And a rack and pinion would be just the solution

for a very long latch.

So I had the idea for making a really long sort of "deadbolt". I needed

a means of transferring rotating motion from a handle to the linear

motion of the latch. And a rack and pinion would be just the solution

for a very long latch.

Normally, for double doors, one locks one door to the top and bottom, and then the second door latches onto the first. But I started thinking about a way of locking the two doors together in one plane without latching the other door at the top. A "barricade bar" that fits into hooks on either side of the double door would do the job, but that would make locking the doors quite awkward.

So I had the idea for making a really long sort of "deadbolt". I needed

a means of transferring rotating motion from a handle to the linear

motion of the latch. And a rack and pinion would be just the solution

for a very long latch.

So I had the idea for making a really long sort of "deadbolt". I needed

a means of transferring rotating motion from a handle to the linear

motion of the latch. And a rack and pinion would be just the solution

for a very long latch.

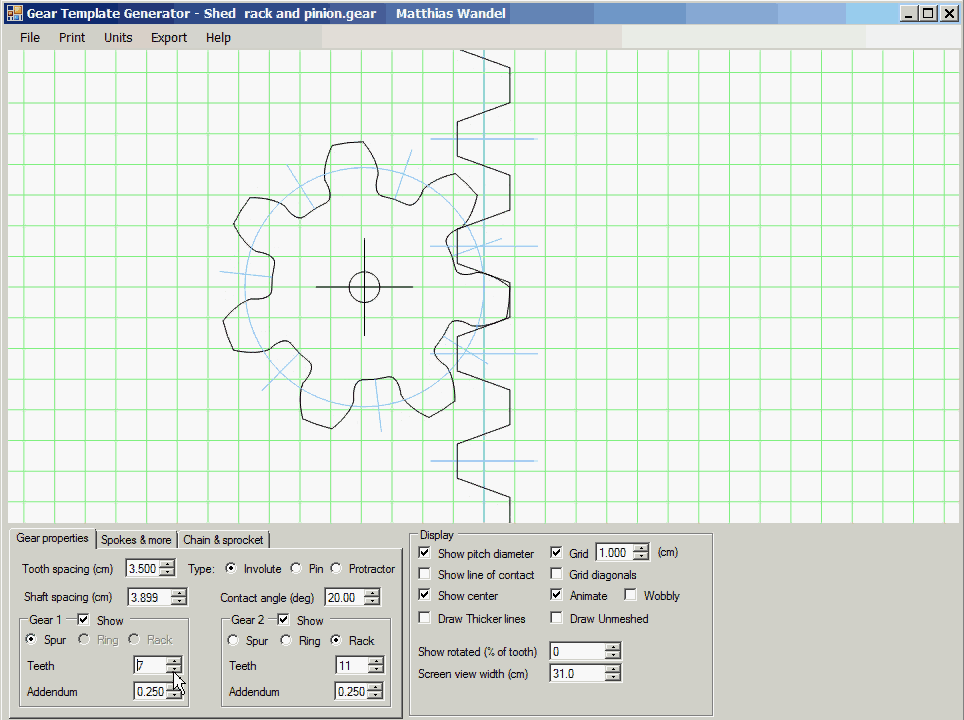

I designed the rack and pinion using my

gear generator program.

I used a 3.5 cm tooth spacing, and a seven tooth pinion against a rack.

I left all the other parameters at their default values.

I designed the rack and pinion using my

gear generator program.

I used a 3.5 cm tooth spacing, and a seven tooth pinion against a rack.

I left all the other parameters at their default values.

This is actually the first time that I have made a wooden rack and pinion.

I cut the parts out on the bandsaw, as usual.

This is actually the first time that I have made a wooden rack and pinion.

I cut the parts out on the bandsaw, as usual.

I smoothed the faces of the teeth and rack using my strip sander. The resulting rack and pinion moved very easily. I made sure to cut away all of the line when I cut the pieces out to ensure my rack and pinion would have a little bit of play. A little bit of play is not a problem, and I don't want these to become tight with humidity changes.

I used birch plywood for the gear and rack. I cut a rabbet into the corner of

what would be my "bolt" and screwed the plywood rack to it. I wanted

to make the rack out of plywood so the teeth aren't liable to break off,

but I wanted the main bolt to be from solid wood for better stiffness.

It's also thicker and less expensive that way.

I used birch plywood for the gear and rack. I cut a rabbet into the corner of

what would be my "bolt" and screwed the plywood rack to it. I wanted

to make the rack out of plywood so the teeth aren't liable to break off,

but I wanted the main bolt to be from solid wood for better stiffness.

It's also thicker and less expensive that way.

I used a 1.5" hole-saw to cut a hole through the sheet metal and door. I then attached

a flange to the outside to provide more bearing surface for the dowel shaft, and

to get the handle away from the sheet metal ribs.

I made the flange out of some exotic hardwood, though I'm not sure exactly what it is,

probably mahogany - it's very dark. I'm hoping that it's fairly weather resistant.

I held it in place with one of my long reach clamps

while I screwed it on.

I used a 1.5" hole-saw to cut a hole through the sheet metal and door. I then attached

a flange to the outside to provide more bearing surface for the dowel shaft, and

to get the handle away from the sheet metal ribs.

I made the flange out of some exotic hardwood, though I'm not sure exactly what it is,

probably mahogany - it's very dark. I'm hoping that it's fairly weather resistant.

I held it in place with one of my long reach clamps

while I screwed it on.

Attaching the guide for the bolt to the other side. I was careful to line it up with the flange

on the other side, so the 1.25" (30 mm) dowel is perpendicular to the door.

Attaching the guide for the bolt to the other side. I was careful to line it up with the flange

on the other side, so the 1.25" (30 mm) dowel is perpendicular to the door.

Next, inserting my very long "bolt".

Next, inserting my very long "bolt".

And attaching the handle to the outside. The handle is made from some scrap of

exotic hardwood flooring. I'm hoping it's weather resistant.

And attaching the handle to the outside. The handle is made from some scrap of

exotic hardwood flooring. I'm hoping it's weather resistant.

Here's how far the bolt extends out. It takes a two turns of the handle

to fully extend it.

Here's how far the bolt extends out. It takes a two turns of the handle

to fully extend it.

I could have made it slightly longer still, but the scrap of 2x4 that I used to make it was only so long.

I added a stop to prevent the bolt from extending too far (not shown). Otherwise, I might extend the bolt past the rack teeth, and then it would be impossible to crank it back!

Cutting the dowel to its final length.

Cutting the dowel to its final length.

And applying some wood preserver/sealer. I had that left over

from sealing my deck at my previous house.

And applying some wood preserver/sealer. I had that left over

from sealing my deck at my previous house.

I'm thinking the handle and flange would be ok without it, but the dowel is only maple, and maple is not that rot resistant.

Weather resistant or not, the handle shouldn't get wet with every rain because it's under

the roof overhang at the front.

Weather resistant or not, the handle shouldn't get wet with every rain because it's under

the roof overhang at the front.

You can also see how the gable end is slightly forward of the doors.

That way, even with driving rain, any water that may hit the gable will run down

and drip off in front of the doors, not behind them.

You can also see how the gable end is slightly forward of the doors.

That way, even with driving rain, any water that may hit the gable will run down

and drip off in front of the doors, not behind them.

Now adding a bracket for the bolt to extend through.

Now adding a bracket for the bolt to extend through.

So with the bolt fully extended, it locks the two door halves into alignment with each

other, which makes sure both doors are closed, even if the door to the right

(seen from the inside) wasn't locked at the top. With just the one bracket near the edge, it locks the doors against

swinging outwards. The doors already can't swing inward because the door's sheet metal

hits the front of the shed.

So with the bolt fully extended, it locks the two door halves into alignment with each

other, which makes sure both doors are closed, even if the door to the right

(seen from the inside) wasn't locked at the top. With just the one bracket near the edge, it locks the doors against

swinging outwards. The doors already can't swing inward because the door's sheet metal

hits the front of the shed.

But I had previously already built a catch for that door, accessible only from the inside.

But I had previously already built a catch for that door, accessible only from the inside.

I wanted to see how well the doors held shut without that, but then realized that it was nearly impossible to close the doors without engaging that latch. Basically, gravity pulls that latch vertical, which closes it.

Sometimes a gust of wind will violently slam a door shut in my house.

With these doors as large as they are, outdoors, and no real door

frame to slam into, I figured that could cause some damage!

Sometimes a gust of wind will violently slam a door shut in my house.

With these doors as large as they are, outdoors, and no real door

frame to slam into, I figured that could cause some damage!

So to prevent the doors from swinging in the wind, I added these built-in door

stoppers to the doors. They just flip down from the door and push against the ground.

So to prevent the doors from swinging in the wind, I added these built-in door

stoppers to the doors. They just flip down from the door and push against the ground.

They usually fall down just from closing the doors, so when opening the door, they are often already dragging on the ground. A good feature, I think.

Next: Optimizing storage in the shed