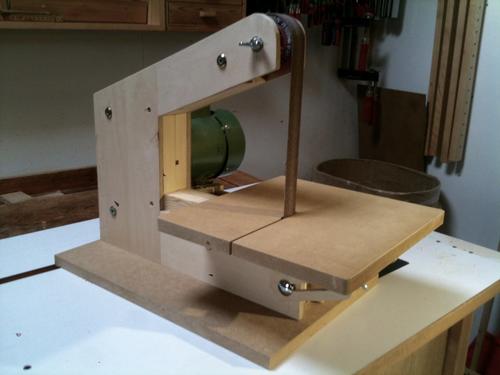

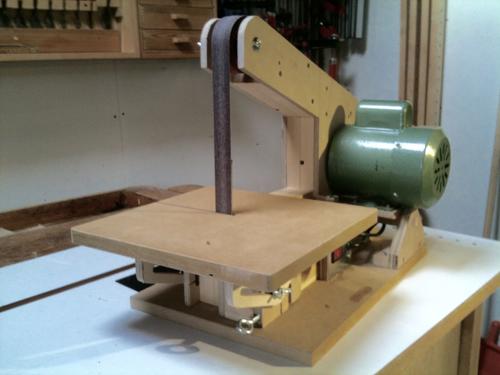

Jens Larsen's strip sander

Jens larsen was inspired by my strip sander build to build a strip sander own design, using some of the ideas from my machine.Jens larsen writes:

Hello Matthias

Remember me? Iíve written you before about my home built bandsaw, blade grinding set-up and a few other things, and am now writing about the belt sander I just built.

I got inspired to build on by your recent article. I happened to have some inline wheels and a motor from a small drill press Iíd picked up for less than 10€ with the intention of converting it into an oscillating spindle sander.

What I didnít have was good quality plywood of the right thickness to simply copy yours, so I set about designing one around some scraps of 9 mm ply, 1x4Ē and 2x4Ē cut offís, and a few other bits. Turned out all right I thought, and runs like a dream.

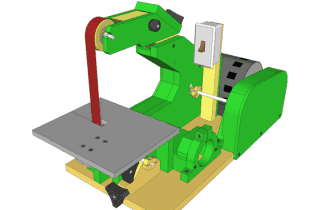

I didnít quite understand why you didnít mount the driving wheel directly on the motor, so decided to do so, and to use the motor mount for tensioning the belt. I liked your belt alignment method, but couldnít fit it neatly in my arrangement, so settled on a variant with a pivoted arm activated by a bolt and nut embedded in a distance piece slightly thicker than the arm. Not much else to add I think, except that the trick is, of course, to get the layout dead right from the start.

I did this by first turning the wheels (and no, I didnít have the guts to do so on the table saw, but used the lathe and disk sander), and checking the design with these and a belt, before proceeding with the actual construction.

I had planned to keep the two halves of the body aligned by four dowels and keeping them together using bolts with wing nuts, but got lazy and ended up using four furniture screws that do both jobs instead. It means having to use a hex key when changing belts, but not much of a problem I thought.

I hope you like it, and as I said all for 7.5 ß for a motor with switch and all, a few pence for bolts, screws and glue, and scraps that would otherwise have ended in the bin.

All the best

Jens Larsen

Matthias comments: I did, at length, consider putting the drive wheel directly on the motor shaft, but most of the motors I have available are open framed motors, with not very long shafts, and pulling in cooling air near the drive shaft. So I figured putting the motor behind the sander was the safer choice

More projects by Jens Larsen:

Jens Larsen's 10.5" bandsaw

Jens Larsen's 10.5" bandsaw Jens Larsen's dust

Jens Larsen's dustcollector Thien-baffle

modifications

Jens Larsen's tenon jig

Jens Larsen's tenon jig

See also:

Strip sander build

Strip sander build Elyasaf's sander

Elyasaf's sander Phillip Kowalsky's sander

Phillip Kowalsky's sander Matthew's strip sander

Matthew's strip sander Strip sander plans

Strip sander plans