I previously made some coat hooks in

2010, but I found myself in need of more.

I previously made some coat hooks in

2010, but I found myself in need of more.

I previously made some coat hooks in

2010, but I found myself in need of more.

I previously made some coat hooks in

2010, but I found myself in need of more.

For expedience, I figured I'd make them without a lathe this time.

My first try was to cut out a shape on the bandsaw and route a roundover on the edges. But the hook looked inelegant. So I made a template for an improved shape.

I traced five of these on some pieces of oak...

I traced five of these on some pieces of oak...

... then cut them out on the bandsaw. I cut pairs of hooks back to

back on the pieces of wood.

... then cut them out on the bandsaw. I cut pairs of hooks back to

back on the pieces of wood.

I think a lot of people would attach a template and use a router follower bit to get the shape smooth but I prefer to just cut it out carefully and smooth the edges with a belt sander.

I had to use my strip sander for part of the inside edges though.

Having two hooks back to back made them much easier to hold

while routing chamfers on the edges. The chamfer looks much

crisper than the roundover I tried first.

Having two hooks back to back made them much easier to hold

while routing chamfers on the edges. The chamfer looks much

crisper than the roundover I tried first.

I used a yoghurt cup to trace a round edge for the board that

they are mounted on, then cut that out on the bandsaw (and sanded

the resulting edge, of course)

I used a yoghurt cup to trace a round edge for the board that

they are mounted on, then cut that out on the bandsaw (and sanded

the resulting edge, of course)

I then rounded the edge of the board with a 1/2" roundover bit.

I then rounded the edge of the board with a 1/2" roundover bit.

Normally, the next step would be to join the hooks to

the board before varnishing, but I figured I'd try it

in a different order this time.

Normally, the next step would be to join the hooks to

the board before varnishing, but I figured I'd try it

in a different order this time.

The parts are easier to varnish when not yet assembled, so I did

that before even cutting the holes and peg ends on the hooks.

The parts are easier to varnish when not yet assembled, so I did

that before even cutting the holes and peg ends on the hooks.

Drilling the holes in the varnished board. The Forstner bit

doesn't cause any tear out.

Drilling the holes in the varnished board. The Forstner bit

doesn't cause any tear out.

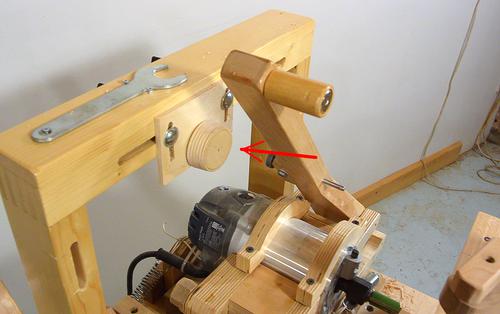

I cut the peg ends on the pantorouter.

I used a round template to make

the dowel. The template is slightly conical so I can fine adjust

the size by moving the guide bearing further back along the dowel.

I reused the template from making

these larger joints,

but with a smaller follower bearing this time, I could use the same template

for 5/8" dowel ends.

I cut the peg ends on the pantorouter.

I used a round template to make

the dowel. The template is slightly conical so I can fine adjust

the size by moving the guide bearing further back along the dowel.

I reused the template from making

these larger joints,

but with a smaller follower bearing this time, I could use the same template

for 5/8" dowel ends.

Cutting the dowel end. I'm always working my way around the cut clock-wise.

That way, the router is always cutting into the wood, so there's no chipout.

Cutting the dowel end. I'm always working my way around the cut clock-wise.

That way, the router is always cutting into the wood, so there's no chipout.

It's normally not advisable to cut in this direction, because the router will pull itself along the wood, but my fingers are far from the router, and with the pantorouter the operating lever gives me a lot of mechanical advantage, so I have good control of the router.

Now gluing in the pegs. Because I cut the holes and dowel ends after

varnishing, I didn't have to worry about not getting any varnish on

those parts. And now, any glue squeezeout ends up on a varnished surface, so

it's easy to wipe off.

Now gluing in the pegs. Because I cut the holes and dowel ends after

varnishing, I didn't have to worry about not getting any varnish on

those parts. And now, any glue squeezeout ends up on a varnished surface, so

it's easy to wipe off.

The pegs protruded out the back a bit, but a router with a straight bit

did a super fast job of cutting those off. Much faster than

flush cutting with a chisel, and

less risk of damaging the surface than even a flush cut saw.

The pegs protruded out the back a bit, but a router with a straight bit

did a super fast job of cutting those off. Much faster than

flush cutting with a chisel, and

less risk of damaging the surface than even a flush cut saw.

To mount the coat hooks on the wall, I just screwed through the front.

Easiest and strongest that way, and once the hooks have coats on them,

the screw can't be seen anyway.

To mount the coat hooks on the wall, I just screwed through the front.

Easiest and strongest that way, and once the hooks have coats on them,

the screw can't be seen anyway.

I started by finding the studs, then holding the hooks where I wanted them and marking where I needed to place the screws so they'd go into the studs.