Grinding a Forstner bit to a custom size

I often use roller skate bearings. These are 22 mm in diameter. The

closest size drill I have to that size is 7/8", which is 22.23 mm.

I often use roller skate bearings. These are 22 mm in diameter. The

closest size drill I have to that size is 7/8", which is 22.23 mm.

I figured it should be possible to grind a 7/8" Forstner bit down by a tiny bit to make a hole just the right size for one of these bearings.

I put the drill bit in a hand drill and made another piece with a notch in it

that the shank of the drill could rest in to help steady it.

I put the drill bit in a hand drill and made another piece with a notch in it

that the shank of the drill could rest in to help steady it.

Then I held this up to my bench grinder, with the piece of wood pressed down on the tool rest to help steady it. With the drill spinning, I slowly pushed it against the wheel, then moved the drill forward and back to grind the sides of the Forstner bit in an even cylindrical manner.

After half a minute of slow grinding, I was down to the size I needed.

After half a minute of slow grinding, I was down to the size I needed.

Fortunately, the points on the edges were still ahead of the main cutting edges, so I didn't need to grind these back any.

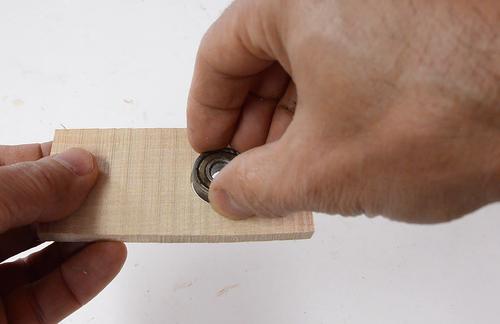

The test hole I drilled with the bearing pressed in made a sort of fidget spinner.

The test hole I drilled with the bearing pressed in made a sort of fidget spinner.

I don't have a use for fidget spinners, so I figured I'd spin it with compressed air until it exploded. But I had to cut some slots into the sides of it to weaken enough. With the extra notches around it, it made a sound like a high-revving engine as the air was blowing against it.

With enough tweaking, and cutting the notches deep enough to weaken the spinner,

it finally exploded. Or at least, I thought it did.

With enough tweaking, and cutting the notches deep enough to weaken the spinner,

it finally exploded. Or at least, I thought it did.

On later analysis of the video, it's clear that the wood came off the bearing first, then probably broke apart when it hit the workbench. But it all happened so fast that, as far as I could tell, it just disappeared in an instant.

See also:

Cheap fortsner bits: Low quality but they drill ok (video only)

Cheap fortsner bits: Low quality but they drill ok (video only) Making a drill index for Forstner bits (video only)

Making a drill index for Forstner bits (video only) Drilling glass (video only)

Drilling glass (video only)To my Woodworking website

Sharpening drill bits

Sharpening drill bits Sharpening

Sharpening Modifying router bits

Modifying router bits Saw blade sharpening jig

Saw blade sharpening jig Wooden gear wear test

Wooden gear wear test