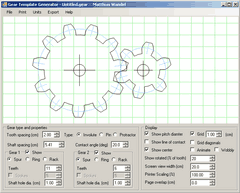

Gear template generator

Also available in French and Spanish

Download HPGL

Some notes about gear design and this gear template generator

This template generator is intended for generating paper templates for cutting low precision gears from plywood, phenolic, or other suitable materials with a band saw.

You can now buy a downloadable gear template generator. More features, runs on your PC |

The gear tooth generation is not perfect. Normally, one rounds the tips of gear teeth a little bit, which this program doesn't do. Also, for gears with less than about 10 teeth, and low tooth angles, it's sometimes necessary to narrow the teeth at the base (undercut) or to alter the geometry (profile shifts). So some combinations with gears of small numbers of teeth may overlap, or jam if they were real. You can check to see if the gears would overlap by selecting the 'animate' and 'two gears' checkboxes for your gears and watching them turn. My non-free gear program will automatically calculate the necessary undercut to make the gears mesh.

Ring gear / planetary motion gears

You can also generate templates for inside gearing, such as would be used for planetary

motion gears. Simply enter a negative number of teeth for one of the gears,

and that gear will be an inside gear. Select a large number for the shaft diameter when

making a template to get a circle around the gear. For more about how to work out

the number of teeth and ratio, see this note on planetary

gear ratios and calculations

Rack and pinion gearing

You can also generate rack and pinion gears. Just enter zero for the number of teeth

of a gear, and the program will draw a straight gear rack instead of a gear for

that gear.

The involute shape of gears is very important for gears that run at high speed. However, for wooden gears, it really doesn't matter very much. Even if you don't cut the gears with an involute shape, the template generator is still useful as a form of protractor using the "dividing plate mode" for dividing the circle into even intervals. For an example of a different method of cutting gears, see my Wooden gear cutting jig

Printing the gear templates

To print the gear template, use the 'Print' button, rather than just printing the web page from the browser.

The print button tells flash to print just the flash contents. It gets dumped to the printer in vector

form, so screen resolution is not a limiting factor. A rather cool feature of flash, I think!

To get the sizes specified to be correct, its best to print a test template, and then measure

the distance between the lines at the top of the image, and enter that under "page width". Subsequent

printouts should be scaled so that the millimeters are exact.

For gears larger than a sheet of paper, the gear is offset from center. That way, multiple

copies can be printed and pasted together to form a gear template up to 40 cm in diameter.

My downloadable gear generator program that I have for sale doesn't need the scale calibration, and can paginate across many pages for larger gears.

I recommend ink jet printers over laser printers for printing gear templates. The fine colour registration requirements of ink jet print heads forces the printer makers to make sure that the image is not stretched or compressed in either direction. With laser printers, a stretch does not cause registration problems, so some laser printer output is sometimes stretched by as much as a percent in one axis. Its best to check that the diameter is consistent along the vertical, horizontal, and diagonal to be sure there is no distortion.

I also used my gear template generator for the gears of my screw advance box joint jig

Also check out my Wood gear cutting jig. I have to admit though that I have not used this jig since writing this gear template generator.

To my Woodworking Website

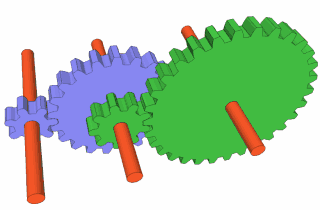

Example plywood gears

Example plywood gears How to make gears

How to make gears Gears with a jigsaw

Gears with a jigsaw Working out gear ratios

Working out gear ratios Right angle gears

Right angle gears