More planer experiments (with the DW735)

I wanted to experiment to see how the knives on the DW735 performed when subjected

to things that aren't meant to go through a planer.

I wanted to experiment to see how the knives on the DW735 performed when subjected

to things that aren't meant to go through a planer.

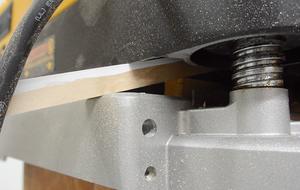

The first test was with some steel. It doesn't take much steel to nick the blades, so I used some staples. I took two pieces of silver maple and put staples in over the edge, with just one prong in the wood, then cut it flush so only the prong was left in the wood.

I then ran that through my DW735, but near the edge, so that I could more easily avoid

the damaged part of the knives later.

I then ran that through my DW735, but near the edge, so that I could more easily avoid

the damaged part of the knives later.

Here you can clearly see a nick in the knives starting right at the staple.

It's a substantial nick.

Here you can clearly see a nick in the knives starting right at the staple.

It's a substantial nick.

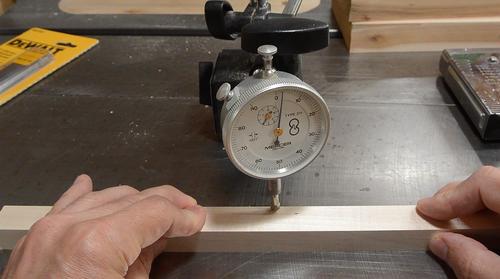

I measured the ridge from the nicked knives with my dial indicator. It was 0.005" high.

I tried the same test on my cheap Mastercraft planer. The ridge on the Mastercraft

planer was 0.006" high. Slightly higher. But then again, the Mastercraft only

has two knives to nick vs. the three in the DeWalt.

I measured the ridge from the nicked knives with my dial indicator. It was 0.005" high.

I tried the same test on my cheap Mastercraft planer. The ridge on the Mastercraft

planer was 0.006" high. Slightly higher. But then again, the Mastercraft only

has two knives to nick vs. the three in the DeWalt.

Other than metal and stone grit, paint is one of the worst things to pass through

a planer. The

titanium dioxide used for the white pigment base of most paints is very hard

and wears blades quickly.

Other than metal and stone grit, paint is one of the worst things to pass through

a planer. The

titanium dioxide used for the white pigment base of most paints is very hard

and wears blades quickly.

I painted one surface of several 50 cm long strips of hardwood white, then planed one of them on the DeWalt planer, followed by a regular piece of wood. I couldn't see any signs of damage to the knives, so I followed it with the other two samples. Still no sign of damage. Maybe the paint wasn't on thick enough, or maybe the artist paint isn't as damaging?

I had a piece of construction lumber that had been painted, about 90 cm (3') long.

I cut a 1 cm wide strip off this wood and passed it through the planer.

I had a piece of construction lumber that had been painted, about 90 cm (3') long.

I cut a 1 cm wide strip off this wood and passed it through the planer.

After planing the strip of wood, I planed another piece of wood, and I could clearly

see some damage to the knives from where I had planed it. I then did the same

test on the cheap Mastercraft planer and didn't see any signs of damage.

After planing the strip of wood, I planed another piece of wood, and I could clearly

see some damage to the knives from where I had planed it. I then did the same

test on the cheap Mastercraft planer and didn't see any signs of damage.

So it looked like the knives in the DeWalt became damaged more easily. But the next day it occurred to me that the damage from paint shouldn't have discrete ridges in it like I had from this sample. So I repeated the test on a different part of the cutter head on the DeWalt. This time, no visible damage. I ran three more strips through at the same place on the knives and still no sign of damage. So the one time where the painted wood caused noticeable damage was probably from grit under the paint.

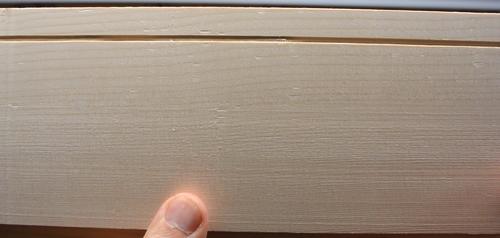

While experimenting with planing paint, I started looking closely at the

planed surfaces, and I noticed divots in the wood from time to time.

While experimenting with planing paint, I started looking closely at the

planed surfaces, and I noticed divots in the wood from time to time.

The sample at left is from planing 3/32" (2.4mm) off a piece of wood on the DeWalt. I suspected these were from shavings circulating around the planer head and getting pushed between the planer's knives and the wood.

Planing just 1/32" (0.8 mm) at a time for eliminated the divoting for the most part.

The sample at left is from the DW735.

Planing just 1/32" (0.8 mm) at a time for eliminated the divoting for the most part.

The sample at left is from the DW735.

Switching to the slow feed rate also mostly eliminated the divoting, but instead of running the wood at half speed, I could just make two shallow passes to get the same result.

And the same test on the Mastercraft planer, planing 3/32" (2.4 mm) off the wood

— very similar divoting.

And the same test on the Mastercraft planer, planing 3/32" (2.4 mm) off the wood

— very similar divoting.

Similar to the DeWalt planer, planing just 1/32" (0.8 mm) off the wood for the

most part eliminated this divoting.

Similar to the DeWalt planer, planing just 1/32" (0.8 mm) off the wood for the

most part eliminated this divoting.

I was starting to wonder what the point of the slow feed rate was, so I took

some maple with some wavy grain (I didn't have any highly figured wood at hand)

and planed that, planing a fair amount off. Both planers had a bit of tear-out

here and there, though hard to see. You can also see some divoting as seen

with the softwood, but not as pronounced.

Click image to enlarge.

I was starting to wonder what the point of the slow feed rate was, so I took

some maple with some wavy grain (I didn't have any highly figured wood at hand)

and planed that, planing a fair amount off. Both planers had a bit of tear-out

here and there, though hard to see. You can also see some divoting as seen

with the softwood, but not as pronounced.

Click image to enlarge.

Taking shallow passes reduced the tear-out, but taking shallow passes AND

using the slow feed rate eliminated the tear-out on this wood.

Taking shallow passes reduced the tear-out, but taking shallow passes AND

using the slow feed rate eliminated the tear-out on this wood.

At left two pieces of wood, top one a shallow pass on the DeWalt at slow speed, bottom one from the Mastercraft planer.

I wanted to get a cut that was as clean as possible. Even with the DeWalt

hooked up to my big dust collector with a 4" dryer hose, I knew there was still a lot of

pressure in the hose, so I disconnected it to let more air out. This cut down on the

divoting. It's hard for a dust collector to take all the air that the DeWalt pushes

out the exhaust port.

I wanted to get a cut that was as clean as possible. Even with the DeWalt

hooked up to my big dust collector with a 4" dryer hose, I knew there was still a lot of

pressure in the hose, so I disconnected it to let more air out. This cut down on the

divoting. It's hard for a dust collector to take all the air that the DeWalt pushes

out the exhaust port.

Looking into the exhaust port, the blower impeller has two sides, one for the chips, the other for the motor cooling air. So the motor's cooling air is also blown into the dust collector. It would have been better if the motor's cooling air didn't add to the air pushed into the dust collector. In the YouTube comments, some complained about the motor on their DeWalt planer overheating. I suspect this may be caused by inadequate airflow. So if your DW735 doesn't suck up all the wood chips, leaving some on the table, it probably has too little airflow and may overheat.

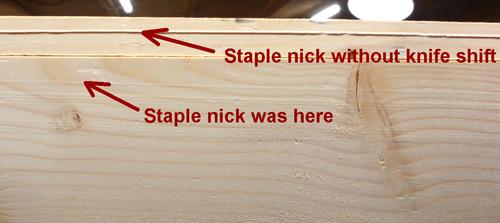

Finally, I loosened the screws on one of the knives and shifted it over by a millimeter.

This for the most part eliminated the ridge left by my staple experiment. By comparison,

the ridge above that is from the staple nick on my Mastercraft planer.

Finally, I loosened the screws on one of the knives and shifted it over by a millimeter.

This for the most part eliminated the ridge left by my staple experiment. By comparison,

the ridge above that is from the staple nick on my Mastercraft planer.

Shifting the knives to the side is much easier on the DeWalt, as is changing knives, as is true for other planers with disposable knives too.

Thanks again to Tegs tools for giving me the planer for free. Check this video walking around Teg's tools in their Rymal road store in Hamilton.

The above was done in 2016. A few years later, I figured, if shifting the kinves helps by mis-aligning the nicks, why not try swapping (or flipping) just ONE of the knives. Sure enough, that made a big difference.

More about planers:

Planer snipe on

Planer snipe onsmall thickness planers

Back to my Woodworking website.

DeWalt 735 planer vs. a cheap one

DeWalt 735 planer vs. a cheap one Changing planer knives

Changing planer knives Sharpening planer knives by hand

Sharpening planer knives by hand Planer blade sharpening machine

Planer blade sharpening machine Delta planer teardown

Delta planer teardown My dad's old

My dad's old Lucian's homemade thickness planer

Lucian's homemade thickness planer Homemade jointer

Homemade jointer