Lucian's homemade jointer/planer

When Lucian sent me photos of his

spindle sander, I noticed it was

on what looked like a homemade jointer. I asked about it.

When Lucian sent me photos of his

spindle sander, I noticed it was

on what looked like a homemade jointer. I asked about it.

Lucian replied:

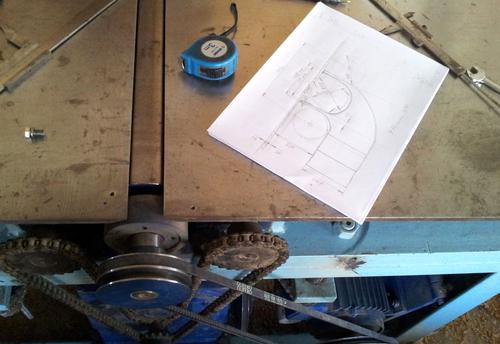

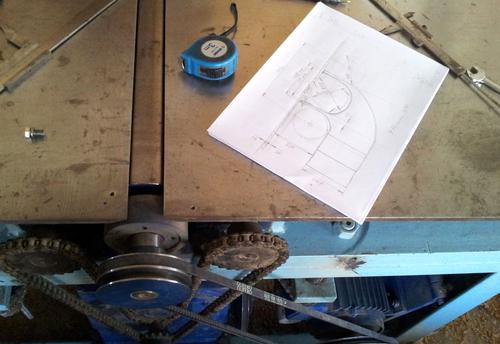

What you noticed in those photos of the Spindle Sander

was that it was standing on a

2-in-1 machine with a generous processing capacity:

A jointer over the table, working width up to 500mm

A thickness machine, working width up to 400mm, which is below the

jointer table and which work in reverse direction of advance motion of

the material.

It's a machine which I designed more then 10 years ago (probably in

2002). Some components were made by friends, and all

other operations (welding, drilling, various metal manufacturing etc.)

and the whole assembly were made by me.

Some technical data:

1. Jointer motor: 230V, 2,2kW, 3000 rpm

2. Advance motion motor for thickness: 230V 1.5KW, 1500 rpm.

3. The planer thickness adjustment (under the table) is done by

an elevation adjustment of a table. There are 4 square threaded screws

fixed under the machine rails, equipped with 4 chain sprocket nuts. The

adjustment table is based on these screw nuts, on which a Gall chain is

passed over. By turning only one nut, the chain determines turning of

the other 3, so all 4 nuts are rotating simultaneously inducing lifting

or lowering the table, bringing it closer or farther from an shaft with

3 knives, depending on the thickness of the material to be planed.

3. The planer thickness adjustment (under the table) is done by

an elevation adjustment of a table. There are 4 square threaded screws

fixed under the machine rails, equipped with 4 chain sprocket nuts. The

adjustment table is based on these screw nuts, on which a Gall chain is

passed over. By turning only one nut, the chain determines turning of

the other 3, so all 4 nuts are rotating simultaneously inducing lifting

or lowering the table, bringing it closer or farther from an shaft with

3 knives, depending on the thickness of the material to be planed.

4. The feed mechanism is by a serrated roller at the infeed and

a smooth roll at the outfeed (after the cutter head). The synchronous

rotation of these two rolls is done also with a chain, driven by

a 1.5KW motor through a worm gear (donít remember exactly what gear ratio has,

there are so many years since I designed it, but I think is 1:40). The

motor and the worm gear box have two-grooved

V-belt pulleys of different diameters and so I can get four different

feed speeds for an optimal adaptation to different

hardness of the wood to be planed.

4. The feed mechanism is by a serrated roller at the infeed and

a smooth roll at the outfeed (after the cutter head). The synchronous

rotation of these two rolls is done also with a chain, driven by

a 1.5KW motor through a worm gear (donít remember exactly what gear ratio has,

there are so many years since I designed it, but I think is 1:40). The

motor and the worm gear box have two-grooved

V-belt pulleys of different diameters and so I can get four different

feed speeds for an optimal adaptation to different

hardness of the wood to be planed.

The machine works very well. It is about 95% complete. The only

thing it needs is a suction system for chips and dust, which,

unfortunately, it spreads all around my workshop.

Lucian

Six months later, lucian sent me When Lucian sent me photos of his

his dust collection system for the jointer/planer:

I would like to share with you the way I solved the problem of dust

generated by my homemade jointer and planer -- dust which spread

throughout my workshop and which was a serious threat to the health of

my lungs.

I would like to share with you the way I solved the problem of dust

generated by my homemade jointer and planer -- dust which spread

throughout my workshop and which was a serious threat to the health of

my lungs.

My homemade jointer and planer constructions determined the

manufacturing of two completely different dust and chips collectors, one

for jointer and another one for planer.

Making the collector for planer functioning mode was simple, it was

basically a surface that make transition from rectangle to circle with

offset and angle (used material was 0.3mm galvanized sheet) and a

cylindrical connector (0.7mm galvanized sheet) for coupling the

exhausting hose. The assembly was done with a 500 W electric soldering

iron by Sn-Pb soldering alloy.

More complicated to make was the collector for the jointer. Because

of low height (130mm is the maximum thickness available), I had

to make this collector from two parts, otherwise mounting

between the two feed rollers would have been impossible.

Basically, after introducing the smaller piece between rollers and

lifting it, the larger piece (which is made of

three parts: a rectangular duct, a rectangle to circle transition and a

cylinder) is positioned just below the smaller piece and rising the

laminated table, the upper part penetrates inside the lower part by 20mm,

becoming a single unit. The materials used are the same, 0.7mm and 0.3mm

galvanized sheet and Sn-Pb solder.

After testing it, a small amount of dust and chips escape to the

melamine table when the machine works as planer, but in the jointer mode

the dust extraction is total!

After testing it, a small amount of dust and chips escape to the

melamine table when the machine works as planer, but in the jointer mode

the dust extraction is total!

Greetings from Romania!

3. The planer thickness adjustment (under the table) is done by

an elevation adjustment of a table. There are 4 square threaded screws

fixed under the machine rails, equipped with 4 chain sprocket nuts. The

adjustment table is based on these screw nuts, on which a Gall chain is

passed over. By turning only one nut, the chain determines turning of

the other 3, so all 4 nuts are rotating simultaneously inducing lifting

or lowering the table, bringing it closer or farther from an shaft with

3 knives, depending on the thickness of the material to be planed.

3. The planer thickness adjustment (under the table) is done by

an elevation adjustment of a table. There are 4 square threaded screws

fixed under the machine rails, equipped with 4 chain sprocket nuts. The

adjustment table is based on these screw nuts, on which a Gall chain is

passed over. By turning only one nut, the chain determines turning of

the other 3, so all 4 nuts are rotating simultaneously inducing lifting

or lowering the table, bringing it closer or farther from an shaft with

3 knives, depending on the thickness of the material to be planed.

When Lucian sent me photos of his

spindle sander, I noticed it was

on what looked like a homemade jointer. I asked about it.

When Lucian sent me photos of his

spindle sander, I noticed it was

on what looked like a homemade jointer. I asked about it.

Bandsaw

Bandsaw Oscillating spindle sander

Oscillating spindle sander

Dad's 20" thickness

Dad's 20" thickness Planer snipe

Planer snipe Planer blade sharpening machine

Planer blade sharpening machine Changing planer knives

Changing planer knives