Shaded Pole Induction Motor - Cooling Fan

This article and video contributed by Ron Walters

A number of these shaded pole motors are sold without a fan. The motor

will run much cooler and will probably last longer if a fan is installed

on the long rotor shaft. I have recycled fan blades from old computer

tower cooling fans. A hub can be machined from metal or plastic with a

small setscrew to attach the blade to the rotor shaft.

A number of these shaded pole motors are sold without a fan. The motor

will run much cooler and will probably last longer if a fan is installed

on the long rotor shaft. I have recycled fan blades from old computer

tower cooling fans. A hub can be machined from metal or plastic with a

small setscrew to attach the blade to the rotor shaft.

The direction the motor is turning will determine the correct

blade configuration to use. You want the fan to blow air across

the shading poles in order to have cooling efficiency.

The direction the motor is turning will determine the correct

blade configuration to use. You want the fan to blow air across

the shading poles in order to have cooling efficiency.

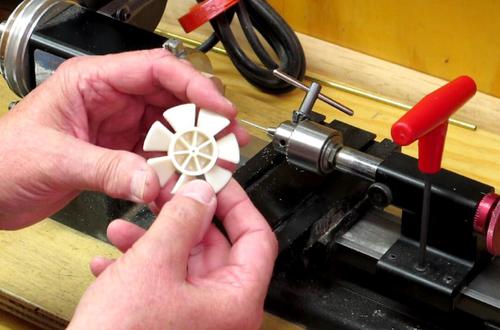

Sometimes small fan blades can be found on eBay. This particular

fan appears to have been intended for one of those wall outlet air fresheners.

Sometimes small fan blades can be found on eBay. This particular

fan appears to have been intended for one of those wall outlet air fresheners.

I machined an adapter hub to fit on the rotor shaft. I wanted

to remove the internal plastic webs of the fan so the hub could be inserted.

I machined an adapter hub to fit on the rotor shaft. I wanted

to remove the internal plastic webs of the fan so the hub could be inserted.

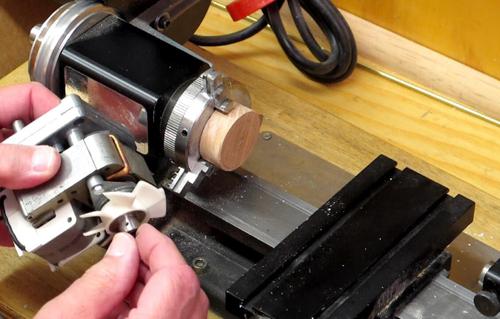

I installed a round wood block in the lathe chuck and used a

small drill bit to accurately center the fan against the wood block.

Hot glue was applied to the back of the fan.

I installed a round wood block in the lathe chuck and used a

small drill bit to accurately center the fan against the wood block.

Hot glue was applied to the back of the fan.

The hot glue will securely hold the fan in position as long as

the machining operations are done slowly and gently.

The hot glue will securely hold the fan in position as long as

the machining operations are done slowly and gently.

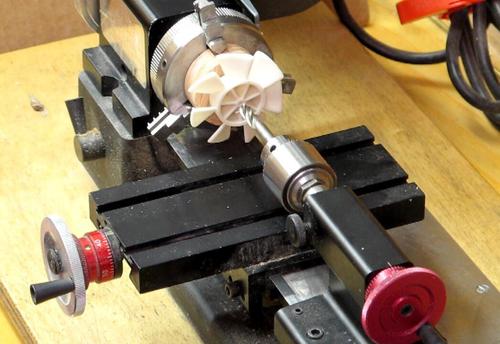

A mill was used to cut away the center portion of the blade...

A mill was used to cut away the center portion of the blade...

...providing room for a boring bar to gently remove the internal

structure of the fan, and providing a snug fit for the adaptor hub.

...providing room for a boring bar to gently remove the internal

structure of the fan, and providing a snug fit for the adaptor hub.

Gently remove the fan from the wood block and clean off the glue.

I decided to cut a clearance hole in the center of the fan so the

setscrew portion of the adaptor would pass through the fan.

I used a little hot glue to secure the fan to the adaptor hub.

Gently remove the fan from the wood block and clean off the glue.

I decided to cut a clearance hole in the center of the fan so the

setscrew portion of the adaptor would pass through the fan.

I used a little hot glue to secure the fan to the adaptor hub.

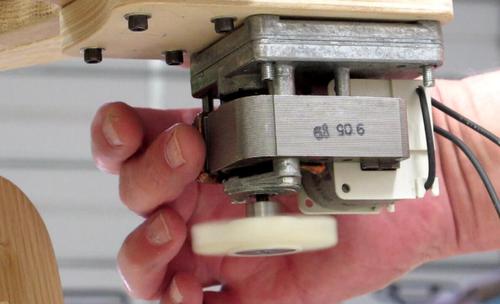

Without a fan the shading poles will get hot enough to

immediately burn your finger. Using this small fan the shading

poles still get hot but they remain within an acceptable limit.

Without a fan the shading poles will get hot enough to

immediately burn your finger. Using this small fan the shading

poles still get hot but they remain within an acceptable limit.

Other projects by Ronald Walters:

Reversing a shaded pole

Reversing a shaded polemotor |

Making wooden U-joints |

Planetary gear drive |

Wooden roller chain

Wooden roller chain

|

Pin gear experiment |