Resawing wide lumber

I had some nice wide boards of quarter sawn white oak that I had been saving for some project. I finally decided to turn this wood into drawer fronts. But to cover all the drawers, I had to resaw the boards in half.

They were too wide to resaw on the table saw. I could have just ripped the boards,

resawed them, and then glue the thin boards back together.

But with the wood being of one piece, I didn't want to introduce

any discontinuities in the grain, so my goal was to cut through the

whole width of the boards.

They were too wide to resaw on the table saw. I could have just ripped the boards,

resawed them, and then glue the thin boards back together.

But with the wood being of one piece, I didn't want to introduce

any discontinuities in the grain, so my goal was to cut through the

whole width of the boards.

As you can see, my table saw wouldn't reach even half way through a board,

despite the fact that I'd

modified the saw to increase the maximum depth of cut

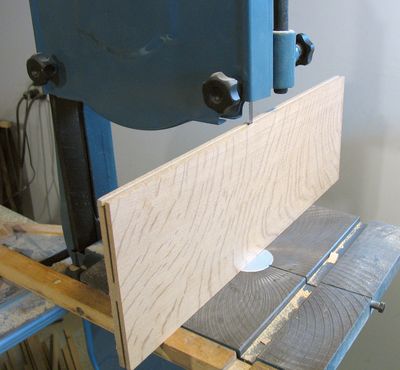

The narrower of the boards was about 20 cm (8") wide, but my 14" bandsaw

blade guides allow for a maximum of 6" depth of cut. However, with the upper blade guide removed,

I did have enough of an opening to push the board through. With the boards

mostly cut apart by my table saw cuts already, and the table saw cuts

helping to guide the blade, I could do the cut without the top blade guide.

I did push the piece very gently through the band saw,

because I only had the bottom blade guide to keep the blade from being

pushed off the wheels.

The narrower of the boards was about 20 cm (8") wide, but my 14" bandsaw

blade guides allow for a maximum of 6" depth of cut. However, with the upper blade guide removed,

I did have enough of an opening to push the board through. With the boards

mostly cut apart by my table saw cuts already, and the table saw cuts

helping to guide the blade, I could do the cut without the top blade guide.

I did push the piece very gently through the band saw,

because I only had the bottom blade guide to keep the blade from being

pushed off the wheels.

I later experimented with building an

upper blade guide

that fits inside the upper wheel enclosure.

With only about 2 cm of wood to cut between my table saw kerfs, this worked out pretty well.

With only about 2 cm of wood to cut between my table saw kerfs, this worked out pretty well.

But I had another board that was 22 cm (nearly 9") wide that I also wanted to resaw.

I just barely had enough room below the cast iron for this other board to fit,

but the housing around the top pulley would have hit the board. So I removed

I just barely had enough room below the cast iron for this other board to fit,

but the housing around the top pulley would have hit the board. So I removed

the top guard. I also had about 5 cm worth of wood between my table saw kerfs

that I needed to cut through, about twice as much as on the other board.

the top guard. I also had about 5 cm worth of wood between my table saw kerfs

that I needed to cut through, about twice as much as on the other board.

So I wedged a piece of maple behind the blade on the top to help keep the blade from slipping back.

But with this hairy setup, and no cover on the top wheel, I only pushed the board half way

through the saw. I then pulled it back out, and cut the rest from the other side.

That way, I didn't have to get as close to the saw. I was kind of afraid that I'd

break the blade, and without a cover, who knows where it might have gone. So I

figured it was best to keep my distance.

But all is well that ends well.

But all is well that ends well.

I'm actually thinking that resawing lumber by first cutting from either side with the table saw is the way to go. Without a special resaw blade, cutting through a board this wide is a bit of a hairy thing to do. Often, the blade will drift a little to the side. Also, with such a deep cut, the blade has a hard time getting the sawdust out fast enough.

If the board being resawn is slightly cupped, resawing it with a straight cut from the bandsaw would not be ideal. But by cutting in as deep as possible from either edge with the table saw first, the resulting cut tends to stay closer to the center of the board even if the board is curved.

If I needed more width, the next thing to do would be to take the saw's table and trunions off and jig up a temorary table a little further down. That would give me another 2.5 cm (1") of depth before hitting the bottom blade guide. The total opening between the top and bottom castings is 30 cm, so if I kluge up some sort of blade guide that doesn't take up part of the opening, the maximum I could resaw this way is 30 cm, or about 12". That is twice as much as the saw is meant to handle, and as much as I'd get if I were to install a 6" riser block.

Update: I have since built a bigger bandsaw, so next time

I need to resaw some stock this wide, I can just run it straight through the saw.

See also:

To my Woodworking website

Cutting up a log on the bandsaw

Cutting up a log on the bandsaw Upper blade guide for resawing wide lumber

Upper blade guide for resawing wide lumber Sharpening bandsaw blades

Sharpening bandsaw blades The physics of bandsaw resawing

The physics of bandsaw resawing Cutting lumber from firewood

Cutting lumber from firewood Splitting logs for lumber

Splitting logs for lumber