We were using this oscillating fan a few times a week. It ran a bit

slow, until eventually it just hummed, with the blades hardly moving.

We were using this oscillating fan a few times a week. It ran a bit

slow, until eventually it just hummed, with the blades hardly moving.

We were using this oscillating fan a few times a week. It ran a bit

slow, until eventually it just hummed, with the blades hardly moving.

We were using this oscillating fan a few times a week. It ran a bit

slow, until eventually it just hummed, with the blades hardly moving.

There are many ways these fans can fail, but if it hums when turned on, and the blade doesn't spin freely, then the problem is a seized bearing -- A very common failure mode for fans like this. In fact, if the fan has not been used for a few years, it's more likely to be seized than not.

So I opened it up. After removing the front of the cage around the fan

blade, I loosen the nut on the fan. The plastic nut holding the fan

blade is typically a counter clockwise (or left hand thread) nut,

which is to say, it needs to be turned clockwise to remove it.

So I opened it up. After removing the front of the cage around the fan

blade, I loosen the nut on the fan. The plastic nut holding the fan

blade is typically a counter clockwise (or left hand thread) nut,

which is to say, it needs to be turned clockwise to remove it.

The fan blade then just pulls off.

Behind the blade is another plastic nut which holds the back of the

blade cage.

Behind the blade is another plastic nut which holds the back of the

blade cage.

The back of the plastic housing has a screw in the middle. Loosening

this removes the housing around the motor.

The back of the plastic housing has a screw in the middle. Loosening

this removes the housing around the motor.

Three more screws to remove on the front to expose the motor.

Three more screws to remove on the front to expose the motor.

I was expecting to take the motor apart (via the four screws holding the

front and back aluminium casting in place), but first I figured I'd try

to spray some WD40 onto the front bearing.

I was expecting to take the motor apart (via the four screws holding the

front and back aluminium casting in place), but first I figured I'd try

to spray some WD40 onto the front bearing.

This immediately allowed the shaft to turn freely.

What happens is that over time, and with a bit of heat, the thinner parts of the lubricating oil evaporate, and the rest oxidizes a bit and turns into a thicker gunk, making it hard for the shaft to turn. Adding some very thin lubricant from the WD40 loosens it, allowing it to turn.

Testing with the fan blade. Definitely working.

Testing with the fan blade. Definitely working.

This repair was much easier than anticipated.

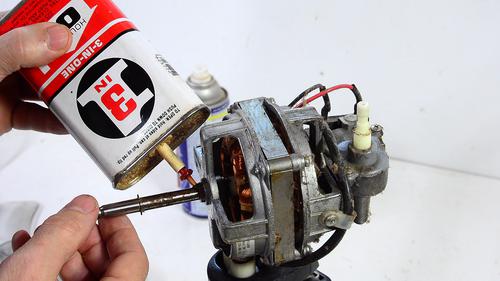

WD40 is excellent for loosening stuck parts, but it's not the best for

permanent lubrication. So I added some 3-in-1 household oil to the

bearings, both front and back, and put it back together. This repair

turned out much easier than I expected.

WD40 is excellent for loosening stuck parts, but it's not the best for

permanent lubrication. So I added some 3-in-1 household oil to the

bearings, both front and back, and put it back together. This repair

turned out much easier than I expected.

For fans like this, if they don't hum or get warm, the failure tends to be the switch, the power cord, or a blown thermal fuse in the motor.

If the motor hums but doesn't run, and if it's hard to turn, its because the bearings are seized. If it hums and turns freely but doesn't run, then it's probably the capacitor connected to the motor, and if it doesn't even hum, it's the motor's thermal fuse, switch, or power cord.

But by far the easiest to fix, and the most common failure mode is when the lubricant has turned to gunk. So check that first before throwing out one of these fans.

John Heisz, having seen my video on fixing a fan, decided to fix his box fan.

Same problem - seized bearings, fixed with a bit of oil.

Another cause of failure for fan motors is that the run capacitor deteriorates,

which causes them to spin slowly, or that the thermal fuse fails, which turned

out to be the cause for the fan below. I gave up on that fan, but did a quick

edit of the video I shot about it anyway.

Air cleaners made from oscillating fans: