Carving canoe paddles on the bandsaw

Recently, I took part in a short canoe trip down Barron Canyon in Algonquin Park. We were using some nice "Grey Owl" straight wooden canoe paddles. During all the paddling, I started contemplating the shape of the paddle, and realized that its shape was something that could mostly be cut with a bandsaw. What I realized was that the cross-section of the paddle could easily be approximated by a series of straight lines along the whole length of the paddle's blade. You can see how the edge of the profile consists of just two straight line segments in the photo at left.

The question was - how to guide a bandsaw to cut that very shape?

So I came up with this idea for a jig. The jig is essentially a sort of channel

that the original paddle can be placed into. Then I take a pencil and drag

it along one of the faces of the paddle. I pull it along so that

the pencil shaft is always flat against part of the paddle profile while

at the same time drawing a line on the edge of my jig. I repeat this with

the pencil facing the opposite direction, but still dragging it along

the same surface as before. These two lines now define the path that the

pencil took along the surface of the paddle.

So I came up with this idea for a jig. The jig is essentially a sort of channel

that the original paddle can be placed into. Then I take a pencil and drag

it along one of the faces of the paddle. I pull it along so that

the pencil shaft is always flat against part of the paddle profile while

at the same time drawing a line on the edge of my jig. I repeat this with

the pencil facing the opposite direction, but still dragging it along

the same surface as before. These two lines now define the path that the

pencil took along the surface of the paddle.

And now I take the sides off my jig and cut along the lines with the bandsaw.

And now I take the sides off my jig and cut along the lines with the bandsaw.

But before I get too far, it helps to cut the basic flat shape of the paddle.

This is pretty easy, just a matter of placing the paddle on a piece of wood,

tracing the outline, and then cutting that out on the bandsaw.

But before I get too far, it helps to cut the basic flat shape of the paddle.

This is pretty easy, just a matter of placing the paddle on a piece of wood,

tracing the outline, and then cutting that out on the bandsaw.

Now it's time to mount the paddle blank in the jig. I'm attaching it with

some drywall screws. I need to set the screws really deep, so that when I

cut out the paddle shape, I won't accidentally cut into the screws.

Now it's time to mount the paddle blank in the jig. I'm attaching it with

some drywall screws. I need to set the screws really deep, so that when I

cut out the paddle shape, I won't accidentally cut into the screws.

That said, I didn't set the screws deep enough one time and cut into them,

so I had to resharpen the blade

And here's where the clever part comes in. I made a board with a big cutout

on the end to use as my fence. The two remaining "prongs" of the board

ride against the edges of my jig, while the middle cutout leaves room for

my unshaped paddle blank.

And here's where the clever part comes in. I made a board with a big cutout

on the end to use as my fence. The two remaining "prongs" of the board

ride against the edges of my jig, while the middle cutout leaves room for

my unshaped paddle blank.

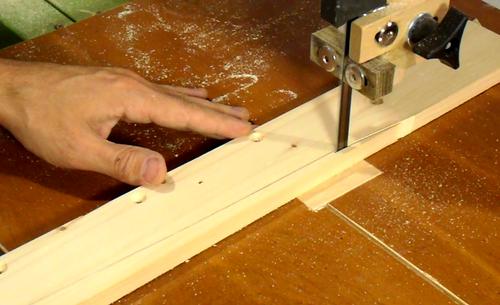

I rigidly mounted this board on my bandsaw. The prongs of the board are

just in front of the blade, and protrude right just past the blade.

The sides of my jig ride against these prongs, and away from the blade.

But my paddle blank sticks out further than the jig's sides,

so it will get cut by the bandsaw blade.

I rigidly mounted this board on my bandsaw. The prongs of the board are

just in front of the blade, and protrude right just past the blade.

The sides of my jig ride against these prongs, and away from the blade.

But my paddle blank sticks out further than the jig's sides,

so it will get cut by the bandsaw blade.

I used a 1/4" bandsaw blade. Not ideal for this deep a cut, but my cut will actually

have a slight bit of twist in it as it goes along, and I figured a narrower

blade would make that easier.

This photo was taken near the end of the first cut. My jig and paddle blank

tilt progressively further to the right as I get to the end.

This photo was taken near the end of the first cut. My jig and paddle blank

tilt progressively further to the right as I get to the end.

After making the first cut, I swapped the boards on either side of my jig.

Now the narrow side is at the top and the wide one at the bottom. So this

cut tilts towards the left as it finishes up.

After making the first cut, I swapped the boards on either side of my jig.

Now the narrow side is at the top and the wide one at the bottom. So this

cut tilts towards the left as it finishes up.

So with two curved cuts, I can shape one side of the paddle blade.

Next I flipped the paddle over and repeated the same procedure

to cut the other side of the blade.

So with two curved cuts, I can shape one side of the paddle blade.

Next I flipped the paddle over and repeated the same procedure

to cut the other side of the blade.

I sketched the profile of the "pear" handle onto my blank and cut that out

with the bandsaw as well.

I sketched the profile of the "pear" handle onto my blank and cut that out

with the bandsaw as well.

I also chamfered the edges of the shaft to make it roughly

octagonal. I did that with a freehand cut.

I also chamfered the edges of the shaft to make it roughly

octagonal. I did that with a freehand cut.

This is as far as I could take the paddle with the bandsaw. Time to finish

it up with some hand tools.

This is as far as I could take the paddle with the bandsaw. Time to finish

it up with some hand tools.

I thinned and smoothed the blade with a spokeshave.

I thinned and smoothed the blade with a spokeshave.

I tried using a hand plane, but I couldn't really follow the curved bandsaw cuts with a plane very well. The spokeshave worked pretty good.

I also used the spokeshave to shape the handle to have a round cross-section.

I used a carving knife to shape the handle...

I used a carving knife to shape the handle...

... plus a little work with the belt sander.

... plus a little work with the belt sander.

All in all, I made three paddles. Two out of spruce (more for practice than anything),

and then one out of oak. The paddle on the right is the original "Grey Owl"

brand paddle.

All in all, I made three paddles. Two out of spruce (more for practice than anything),

and then one out of oak. The paddle on the right is the original "Grey Owl"

brand paddle.

I actually like the second practice paddle I made the best (second from left). It's the lightest, but I think it's still strong enough for paddling because I made it a bit thicker than the hardwood one. It will be more likely to get nicked because the wood is soft, but I probably won't be abusing it that much. Spruce also rots faster than the ash and cherry of the Grow Owl or the oak I used for my third paddle. But rotting is something that takes years of continuous moist conditions. I put three coats of an oil based varnish the paddles, so the wood itself should stay dry unless it were to go on a really long canoe trip.

The spruce paddles are cut from one piece, but the hardwood one is laminated from three pieces. I used Titebond 3 to glue the strips of oak together. The manufacturers make great claims about how waterproof Titebond 3 is. I'm hoping the claims are true.

I found a "how i'ts made" episode on

making canoe paddles

on YouTube. Interestingly enough, they are making "Grey Owl" paddles in the

video, the same brand that I copied. I was really keen on seeing how

they shaped the profile of the blade, but

that step was skipped over. Maybe that step is a "trade secret". But

when you look at how low-tech the operation is, I wouldn't be surprised if

they used something very similar to my method to shape their paddles!

| I shot video of much of the process. In fact, a lot of the photos in this article are extracted from the video because I neglected to take photos of every step. |

And here are the canoe paddles, nine years later, in 2019. The paddles only get

used a few times each summer. The varnish on the oak paddle is a bit banged up.

The spruce paddle (the left one) is less banged up. Possibly the varnish gets

less scraped with the softwer wood?

And here are the canoe paddles, nine years later, in 2019. The paddles only get

used a few times each summer. The varnish on the oak paddle is a bit banged up.

The spruce paddle (the left one) is less banged up. Possibly the varnish gets

less scraped with the softwer wood?

If you are wondering about the bandsaw that I'm using - this is my

second homemade bandsaw.

Numerous people have been asking about buying plans for

my first homemade bandsaw, but I didn't

want to sell plans for that one because I had some ideas for how to build

an even better one. Soon after I wrote about that bandsaw, I started

playing around with CAD designing a more refined 16" bandsaw.

I finished that saw about a month ago (mid July), but putting together a plans

package takes a huge amount of time, so I have refrained from writing

about it (although you can see a few more glimpses of it in my

kids table article and video).

If you are wondering about the bandsaw that I'm using - this is my

second homemade bandsaw.

Numerous people have been asking about buying plans for

my first homemade bandsaw, but I didn't

want to sell plans for that one because I had some ideas for how to build

an even better one. Soon after I wrote about that bandsaw, I started

playing around with CAD designing a more refined 16" bandsaw.

I finished that saw about a month ago (mid July), but putting together a plans

package takes a huge amount of time, so I have refrained from writing

about it (although you can see a few more glimpses of it in my

kids table article and video).

More about this homemade bandsaw here. I also have a very comprehensive set of plans for sale for this bandsaw.

More about bandsaws

See also:

Back to my woodworking website

Pirate sword

Pirate sword Curvy board

Curvy board Carving a chair seat on the table saw

Carving a chair seat on the table saw Lawn chair build

Lawn chair build Corner shelf for a barbecue

Corner shelf for a barbecue Kid's wagon

Kid's wagon Building a sandbox

Building a sandbox Balancing board

Balancing board