Making a featherboard hold down

I recently found myself in need of a featherboard on my table saw.

A feather board is a pretty easy thing to cut out on the bandsaw. The trickier

part is attaching it to the table saw.

I recently found myself in need of a featherboard on my table saw.

A feather board is a pretty easy thing to cut out on the bandsaw. The trickier

part is attaching it to the table saw.

Rummaging through my miscellaneous hardware, I first tried to use the washers

that came with my delta tenon jig,

but these washers were barely big enough to hold in the slot, and the countersink

in the bottom of the washers only allowed for a relatively small screw.

Rummaging through my miscellaneous hardware, I first tried to use the washers

that came with my delta tenon jig,

but these washers were barely big enough to hold in the slot, and the countersink

in the bottom of the washers only allowed for a relatively small screw.

I also found some T-nuts that almost fit in the slot. I only had to grind the nut flat on

two spots on the outside for it to slide in. The prongs of the nut actually

help to keep the nut from turning, though I ground the points flat so they wouldn't

protrude above the table surface.

Making the screw knob

The T-nut that best fit the T-slot had a 3/8 inch thread to it, which is bigger

than I had knobs for, and bigger than knobs you can get at the Home Depot.

I could of course have solved the problem by just gluing a wing nut onto

a cut off bolt or something like that, but I decided that I should make a nice

looking knob myself.

The T-nut that best fit the T-slot had a 3/8 inch thread to it, which is bigger

than I had knobs for, and bigger than knobs you can get at the Home Depot.

I could of course have solved the problem by just gluing a wing nut onto

a cut off bolt or something like that, but I decided that I should make a nice

looking knob myself.

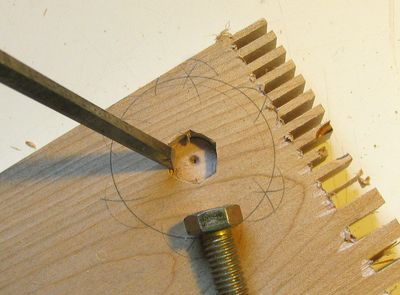

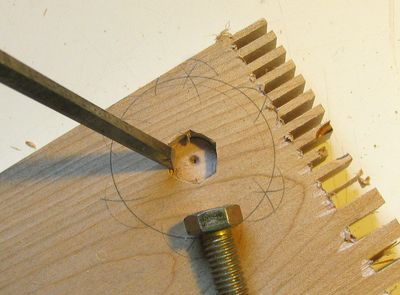

I started by drilling a hole just smaller than the hex head of a 3/8" screw,

and chiseling out a hexagon just a little smaller than the screw head.

I did this just in a piece of scrap wood. You can see my markings for

the knob outline, which I had made with a compass. I had previously used this

piece of scrap wood for testing my box joint

jig, which is why there are comb shaped cuts in the piece of wood.

Next I cut out the knob outline on the bandsaw. I cleaned up the inside rounds

with a quarter round file, and the outsides with the flat side of the file.

Next I cut out the knob outline on the bandsaw. I cleaned up the inside rounds

with a quarter round file, and the outsides with the flat side of the file.

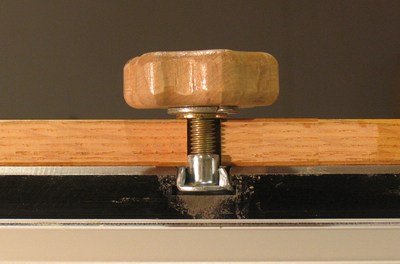

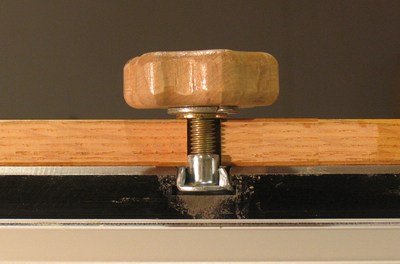

Next I used a 1/4" round router bit on both sides of the knob to give it some nice

round edges, and then pressed in the screw. I roughened up the hexagon a little

bit on the bench grinder just to get it to grip better. As an afterthought,

I also put some varnish on the insides of the hole as I pressed the bolt in,

which I figure might help it get stuck a little better too.

Next I used a 1/4" round router bit on both sides of the knob to give it some nice

round edges, and then pressed in the screw. I roughened up the hexagon a little

bit on the bench grinder just to get it to grip better. As an afterthought,

I also put some varnish on the insides of the hole as I pressed the bolt in,

which I figure might help it get stuck a little better too.

But for good measure I then put a washer on top, which I secured by grinding a

countersink hole shaped notch on either side, and put a 5/8" #4 wood

screw in each notch.

But for good measure I then put a washer on top, which I secured by grinding a

countersink hole shaped notch on either side, and put a 5/8" #4 wood

screw in each notch.

The featherboard itself was pretty straightforward to make.

I cut it freehand on my bandsaw, without even marking lines on it

beforehand. That's why the lines are a little bit wavy.

I made the fingers relatively narrow, so that they would flex easily,

and make the whole board relatively soft.

The featherboard itself was pretty straightforward to make.

I cut it freehand on my bandsaw, without even marking lines on it

beforehand. That's why the lines are a little bit wavy.

I made the fingers relatively narrow, so that they would flex easily,

and make the whole board relatively soft.

For the mounting holes, I had to drill some slightly oversize holes,

because the neck of the T-nut actually protrudes above the table saw surface a little bit.

So the neck of the T-nut has to fit in the holes on the featherboard.

Rummaging through my miscellaneous hardware, I first tried to use the washers

that came with my delta tenon jig,

but these washers were barely big enough to hold in the slot, and the countersink

in the bottom of the washers only allowed for a relatively small screw.

Rummaging through my miscellaneous hardware, I first tried to use the washers

that came with my delta tenon jig,

but these washers were barely big enough to hold in the slot, and the countersink

in the bottom of the washers only allowed for a relatively small screw.

I recently found myself in need of a featherboard on my table saw.

A feather board is a pretty easy thing to cut out on the bandsaw. The trickier

part is attaching it to the table saw.

I recently found myself in need of a featherboard on my table saw.

A feather board is a pretty easy thing to cut out on the bandsaw. The trickier

part is attaching it to the table saw. The T-nut that best fit the T-slot had a 3/8 inch thread to it, which is bigger

than I had knobs for, and bigger than knobs you can get at the Home Depot.

I could of course have solved the problem by just gluing a wing nut onto

a cut off bolt or something like that, but I decided that I should make a nice

looking knob myself.

The T-nut that best fit the T-slot had a 3/8 inch thread to it, which is bigger

than I had knobs for, and bigger than knobs you can get at the Home Depot.

I could of course have solved the problem by just gluing a wing nut onto

a cut off bolt or something like that, but I decided that I should make a nice

looking knob myself.

Next I cut out the knob outline on the bandsaw. I cleaned up the inside rounds

with a quarter round file, and the outsides with the flat side of the file.

Next I cut out the knob outline on the bandsaw. I cleaned up the inside rounds

with a quarter round file, and the outsides with the flat side of the file.

Next I used a 1/4" round router bit on both sides of the knob to give it some nice

round edges, and then pressed in the screw. I roughened up the hexagon a little

bit on the bench grinder just to get it to grip better. As an afterthought,

I also put some varnish on the insides of the hole as I pressed the bolt in,

which I figure might help it get stuck a little better too.

Next I used a 1/4" round router bit on both sides of the knob to give it some nice

round edges, and then pressed in the screw. I roughened up the hexagon a little

bit on the bench grinder just to get it to grip better. As an afterthought,

I also put some varnish on the insides of the hole as I pressed the bolt in,

which I figure might help it get stuck a little better too.

But for good measure I then put a washer on top, which I secured by grinding a

countersink hole shaped notch on either side, and put a 5/8" #4 wood

screw in each notch.

But for good measure I then put a washer on top, which I secured by grinding a

countersink hole shaped notch on either side, and put a 5/8" #4 wood

screw in each notch.

The featherboard itself was pretty straightforward to make.

I cut it freehand on my bandsaw, without even marking lines on it

beforehand. That's why the lines are a little bit wavy.

I made the fingers relatively narrow, so that they would flex easily,

and make the whole board relatively soft.

The featherboard itself was pretty straightforward to make.

I cut it freehand on my bandsaw, without even marking lines on it

beforehand. That's why the lines are a little bit wavy.

I made the fingers relatively narrow, so that they would flex easily,

and make the whole board relatively soft.

Table saw insert

Table saw insert Shirt sucked into table

Shirt sucked into table Table saw sled

Table saw sled