Bench Mortiser wall mount

This article and video contributed by Ron Walters

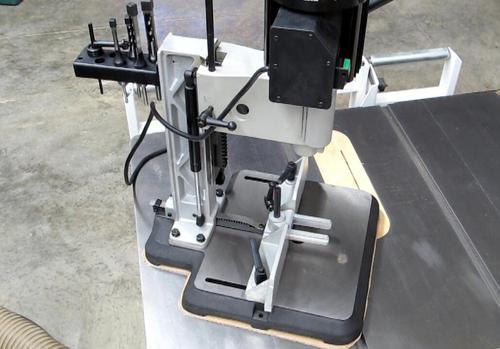

I have long wanted a bench mortiser, and when the Delta 14-651 went on sale I

could no longer resist.

I have long wanted a bench mortiser, and when the Delta 14-651 went on sale I

could no longer resist.

It was larger and heavier than I had remembered (I had not seen one in a while). I did not want it in the way taking up valuable bench space and it is too heavy (~60 pounds) and awkward to be moving around all of the time.

I looked at ways to utilize one of the recessed pockets along the side of my steel building. I have done this before with my 2 for 1 Bench Grinder Mount, Battery Charger Mount and with the Scissors Extension Lights.

I could relocate my clamp storage and install a shelf behind where my

jointer normally sits. I don't anticipate using the mortiser that often

so having to move the jointer once in a while is not much of an

inconvenience.

I could relocate my clamp storage and install a shelf behind where my

jointer normally sits. I don't anticipate using the mortiser that often

so having to move the jointer once in a while is not much of an

inconvenience.

The steel building is bolted together. The 5/16" bolts are long enough

to allow the use of a rod coupler (a long threaded nut). Four

bolts would be adequate to hold the 2x4 shelf support to the side of the

building.

The steel building is bolted together. The 5/16" bolts are long enough

to allow the use of a rod coupler (a long threaded nut). Four

bolts would be adequate to hold the 2x4 shelf support to the side of the

building.

I laminated three pieces of 1/2" construction plywood to make a thick

sturdy shelf. The shelf was edged with oak.

I laminated three pieces of 1/2" construction plywood to make a thick

sturdy shelf. The shelf was edged with oak.

A heavy-duty steel shelf bracket was used as a main support for the

shelf. I attached the bracket to the shelf and to the 2x4 with lag

bolts.

A heavy-duty steel shelf bracket was used as a main support for the

shelf. I attached the bracket to the shelf and to the 2x4 with lag

bolts.

The bench mortiser has a very long lever. A good deal of force is applied to the hollow chisel to force it into the wood. Besides the weight of the mortiser, the force of the lever would place a heavy load on a shelf. I wanted a substantial support member between the front edge of the shelf and the building. It would need to clear an existing water line, so it would need to be installed after the shelf was in place.

The shelf and supports were given two coats of varnish and then the

shelf was bolted to the side of the building.

The shelf and supports were given two coats of varnish and then the

shelf was bolted to the side of the building.

Then the long front support and side supports were installed.

Then the long front support and side supports were installed.

The water pipe is held in place by clamps bolted to the side of the

building. I made two supports for the sides of the shelf, which would

utilize the existing water pipe clamps. These supports prevent any

tendency for the shelf to twist. The side supports just wedge in place

and a small corner bracket holds them in position.

The water pipe is held in place by clamps bolted to the side of the

building. I made two supports for the sides of the shelf, which would

utilize the existing water pipe clamps. These supports prevent any

tendency for the shelf to twist. The side supports just wedge in place

and a small corner bracket holds them in position.

The mortiser fence is positioned with a rack and pinion mechanism. I

drilled a hole in the 2x4 support that allows the rack to travel an

additional 1-1/2". This allowed me to position the mortiser as close to

the building as possible, which also helps reduce the strain

on the shelf.

The mortiser fence is positioned with a rack and pinion mechanism. I

drilled a hole in the 2x4 support that allows the rack to travel an

additional 1-1/2". This allowed me to position the mortiser as close to

the building as possible, which also helps reduce the strain

on the shelf.

The shelf is set at 42" above the floor so the jointer (handles) would

fit under it. This is actually a better height for me than a workbench

and makes it easier to see the chisel positioning.

The shelf is set at 42" above the floor so the jointer (handles) would

fit under it. This is actually a better height for me than a workbench

and makes it easier to see the chisel positioning.

I made a test run, making a mortise and drilling a square hole. It works

well.

I made a test run, making a mortise and drilling a square hole. It works

well.

The mortiser is out of the way but easily accessible.

The mortiser is out of the way but easily accessible.

See also:

Various shop solutions

Various shop solutions