A not so great jobsite saw

I was supposed to do a sponsored review of this saw, but as it turned out, this saw is best reviewed un-sponsored :)

This table saw was given to me for doing a sponsored review of it.

This table saw was given to me for doing a sponsored review of it.

I mentioned that I was going to review this saw in this article and video, but that was before I opened the box. Once I opened the box, I realized a paid review for this saw was not going to do well.

I thought a long time about whether I should do a review of it anyway, just to alert people for issues with jobsite saws to look out for, but didn't want to hurt the sponsor. But then I realized, I really shouldn't let sponsorships dictate what I do or not. So I decided to go ahead with the review, but not talk about the brand of saw.

There are two classes of jobsite saws. The ultra cheap ones with a flimsy plastic

base and stamped sheet metal mechanism on the inside, such as the "Delta" on at left.

These will cut wood, but they are very loud and inaccurate, and, in my opinion,

dangerous. They can be bought new sometimes for as little as $100.

There are two classes of jobsite saws. The ultra cheap ones with a flimsy plastic

base and stamped sheet metal mechanism on the inside, such as the "Delta" on at left.

These will cut wood, but they are very loud and inaccurate, and, in my opinion,

dangerous. They can be bought new sometimes for as little as $100.

The other class of jobsite saw costs on the order of $400 Canadian. These usually have the internals made out of cast aluminium, with the saw motor raising and lowering along two steel rods. This type of saw is larger and more precise and robust than the really cheap jobsite saws. I used to think that this grade of jobsite saw would make a decent substitute for a hybrid table saw or old contractor saw, but the more I look at this type of saw, the less I think they are suitable for furniture making.

At right in the picture at left is my homemade table saw. My homemade table saw is not as good as the $400 jobsite saws, but I think it's better than the really cheap ones.

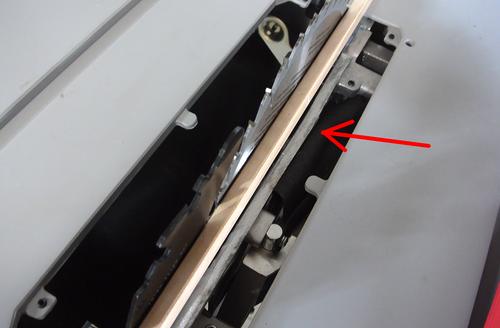

The first thing I noticed about this saw, even before I pulled the saw out of the box, is

that this aluminium part, which holds the motor mount, is bent. I have a straight piece

of wood next to it in this photo to help illustrate this. The shipping box showed no

sign of the sort of damage that would lead to this internal part getting bent, so

this must have come out of the factory like that! With various problems, I sent

the first saw back, but the second one had a similar bend to it.

The first thing I noticed about this saw, even before I pulled the saw out of the box, is

that this aluminium part, which holds the motor mount, is bent. I have a straight piece

of wood next to it in this photo to help illustrate this. The shipping box showed no

sign of the sort of damage that would lead to this internal part getting bent, so

this must have come out of the factory like that! With various problems, I sent

the first saw back, but the second one had a similar bend to it.

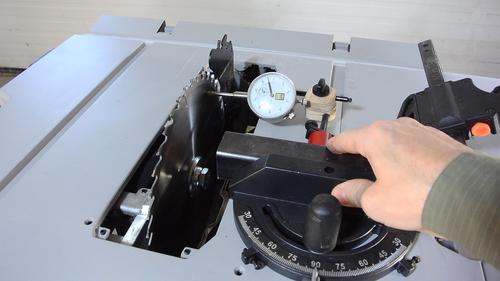

On the first saw they sent me, checking the blade alignment, despite this bend, it

was spot on. The second one had the same bend, but the blade was misaligned so

that the blade, towards the back, was a whole millimeter

further to the left than on the near side. At least with this direction of

misalignment, the blade would not pinch the wood against the fence so long as the

fence is on the right.

On the first saw they sent me, checking the blade alignment, despite this bend, it

was spot on. The second one had the same bend, but the blade was misaligned so

that the blade, towards the back, was a whole millimeter

further to the left than on the near side. At least with this direction of

misalignment, the blade would not pinch the wood against the fence so long as the

fence is on the right.

The second thing I noticed is a hole in the bottom of the shroud around the blade.

That kind of defeats the point of having a shroud that you can hook a vacuum cleaner up to.

The second thing I noticed is a hole in the bottom of the shroud around the blade.

That kind of defeats the point of having a shroud that you can hook a vacuum cleaner up to.

I later found a broken piece of plastic in the packaging, which was a cover that used to cover this hole. But it was broken off even before I received the saw on both saws they sent me.

This is a minor problem, nothing a piece of duct tape couldn't fix, but that shouldn't be necessary on a new saw.

The next thing I noticed was the blade has quite a bit of wobble. The parts that

hold the blade weren't sufficiently precise. On jobsite saws, the arbour flange that is

on the bearing side is typically not bonded or press fit to the arbour, which means it's

not as precisely on there and doesn't give the blade as good a support as it should.

The next thing I noticed was the blade has quite a bit of wobble. The parts that

hold the blade weren't sufficiently precise. On jobsite saws, the arbour flange that is

on the bearing side is typically not bonded or press fit to the arbour, which means it's

not as precisely on there and doesn't give the blade as good a support as it should.

You can also see the throat insert plate on this saw is relatively shallow. This makes it just about impossible to make your own zero clearance insert throat plate for this saw. However, this is a problem with all the jobsite saws I have seen.

The slots in the table measured .0745", 0.05" less than 3/4 of an inch, so

none of my table saw jigs would fit into it. It was about .005", or about 0.1 mm

too small, so that accessories designed to fit into a 3/4 table saw slot would not

fit. It turns out, the slot is exactly 19 mm, so maybe they figured no harm in rounding

it down a tiny bit to 19 mm. I could of course make my jigs narrower, but some of

my jigs use 3/4" bar stock to slide in the slot, and I can't easily cut that down

by 0.1 mm.

The slots in the table measured .0745", 0.05" less than 3/4 of an inch, so

none of my table saw jigs would fit into it. It was about .005", or about 0.1 mm

too small, so that accessories designed to fit into a 3/4 table saw slot would not

fit. It turns out, the slot is exactly 19 mm, so maybe they figured no harm in rounding

it down a tiny bit to 19 mm. I could of course make my jigs narrower, but some of

my jigs use 3/4" bar stock to slide in the slot, and I can't easily cut that down

by 0.1 mm.

But not everything about this saw is terrible.

But not everything about this saw is terrible.

Some of the good points about this saw:

* It has a large table, with the right part of the table able to pull out for ripping wider stock (most jobsite saws have this feature). It also has an outfeed support that can be pulled out on the back. The top of this support is bevelled, so if the stock droops down a bit by the time it gets to it, it pushes it back up. This is a nice feature. For some jobsite saws, this would be an extra cost add on.

* It has a soft start. I consider this a nice safety feature, because if your fingers or some piece of wood is touching the blade, it won't immediately cut or throw them. It also helps if the saw has to run off a long extension cord. Once it's running, it runs at a constant speed, even while cutting, unlike a lot of jobsite saws that spin very fast when under no load. It also makes the saw run a bit quieter.

* It has a riving knife, that can be raised to attach a guard to the top, lowered to riving knife height, or lowered even further. A button and a small thumb screw are used to fix and lock it at these detent positions.

* The saw comes with a push stick attached to it. The push stick is more the "stick" type push stick. Unfortunately, it only comes with one, and I really think these should be used in pairs.

* The built in outfeed extension is very nice.

* The fence locks on the front and back. The cool thing is, it locks on the front first, which squares it up, before the lock on the back engages. Often, fences that lock on the back can be put on non-square if you aren't careful.

Further playing around with it

Further playing around with it

I made some cardboard shims and inserted those under the screws that mount the rods that the motor unit slides up and down on, and this eliminated most of the sawblade's misalignment. But on further investigation, I realized this was a pointless exercise, because the rear trunnion had about 1 mm of lateral play in it. Aslo, the 90 degree stop, which is against the bottom of the table, causes the whole table to flex upwards when pushing the saw hard against that!

But I keep tinkering with this saw. The rear trunnion is made of two halves, and I was able to disassemble it, file away part of the mounts to bring the halves closer together, and now it no longer has any play. The front trunnion also had play in it, which I eliminated in a similar fashion. All the screws on the saw were surprisingly easy to undo. It appears they didn't use any tread locker when they assembled this saw in the factory.

I was also able to widen the miter slots to their proper dimension with lots of scraping. I keep wavering back and forth between "this is the worst jobsite saw, ever" and "I can make this saw work ok". It's possible that both statements are true at the same time.

It's just a jobsite saw

The company that sells these sometimes has sales with deep discounts. They are known more for having good sales than having the highest quality tools. This saw, at $450 + tax (Canadian dollars) list price, is not a great deal. Even for $300, you can buy a better quality jobsite saw. But I have seen it on sale for $350, which I think might be more appropriate. Sometimes this company sells some tools at half price. If this saw was ever discounted that deeply, it might be worth buying.

The thing about jobsite saws is, they aren't meant for precision woodworking. I got a better prospective on that when I visited my sister. She has a Bosch jobsite saw she bought used (The Bosch is a better saw than this one). She had never changed the banged up blade that was in it when she bought it and didn't know how to. She only used it for working on some outside construction. Used like that, with no vacuum attached, and just cutting rough lumber, the issues with this saw don't really matter.

After looking at this saw, I have been looking more closely at jobsite saws when I see them, and the more I look at them, the less I think they are suitable for making furniture.

More about table saws:

More reviewed items:

Back to my woodworking website.

Delta hybrid table saw

Delta hybrid table saw My first table saw

My first table saw Homemade table saw

Homemade table saw Advantages of a brushless cordless drill

Advantages of a brushless cordless drill Tap and die set, tool bag

Tap and die set, tool bag Delta tenon jig review

Delta tenon jig review LED vs. CF

LED vs. CF