One of my hobbies is turning segmented wood. For that, I need to cut many small segmented wood pieces with very accurate angles. There are many commercial miter saws on the market, but I built my own of plywood. Those cheap saws are not rigid, the only good one is the Festool Kapex saw, but it is very big and very expensive. Many saws have sliding action, but I do not need that because my pieces are rather small. Sliding saws must be very solidly built, so that when moving the saw blade through the wood it cannot deflect sideways. I have also not seen any saw with good dust collection.

In segmented wood turning, segments are used to make rings and these rings are glued in a brick wall pattern to make a bowl shape. Rings can have 12 to 36 segments. The segment's miter angle must be very accurate.

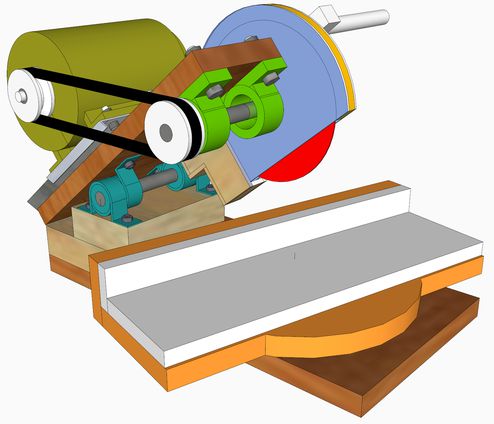

My saw's frame is made of 27 mm birch plywood. The upper frame is hinged with two pairs of 20 mm bearings on the same shaft.

The motor is installed on a standard motor mount plate. Belt tension can be adjusted with a setscrew. The motor is a 3-phase motor driven by an inverter and its speed can be adjusted. On the handle is a micro switch, pressing it with the fingers starts the motor and when it's released the motor stops. The motor must be stopped after each cut so the spinning blade will not contact the just cut piece when lifted back up.

The motor is mounted so that the upper (pivoting) frame is nearly balanced.

The blade guard is made of polycarbonate. The dust hood is made of plywood pieces. It's very effective in dust removal.

When starting to make segments, the first cut is made, then the length stop is locked. The work piece is then flipped over and clamped against the fence and stop block with a wedge between the wood and an off-centre disk.

When making very short pieces a hold down stick can be used to support the cut piece and protect my hand.

Here are some examples of my segmented turnings.

There is also a

SketchUp CAD model of the miter saw

See also:

Pekka's segmented

Pekka's segmented Pekka's homemade

Pekka's homemade Pekka's tilting router lift

Pekka's tilting router lift