Simon Heslop's table saw

Simon Heslop writes:

Simon Heslop writes:Hi Matthias,

You might find this interesting. I've built a table saw based heavily on the one you built recently. I've attached some photos as well as a somewhat crude SketchUp model.

Even though you said it's probably not worth building a saw like this, I

thought it'd be ideal for my small garage (the photo makes it look

bigger than it is — I have trouble moving around the place) as I could

incorporate it into the existing workbench, retracting the blade below

the surface when not in use. I'm also not sure how much use I'd get out

of a table saw to justify buying one and rearranging the garage to fit

it.

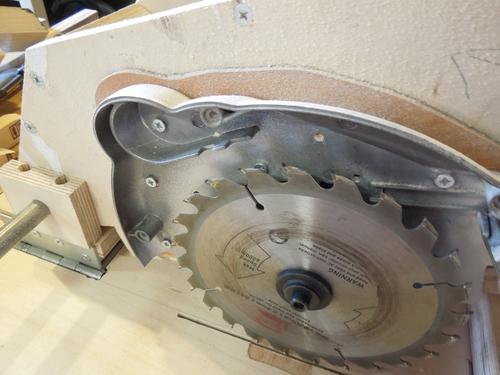

I built it with (what I'd consider to be) a minimum of tools, all of

which are pretty much the cheapest and lowest quality of their kind

available. The bandsaw is as fancy as it got. I bought it second hand at

a car boot sale for £20 and thought I'd really wasted my money until I

got a new blade for it, but it still leaves a fairly wobbly and

off-square cut. The cover is off to show off the cheap construction. All

of the stuff I cut with it I could've cut with the jigsaw though.

I built it with (what I'd consider to be) a minimum of tools, all of

which are pretty much the cheapest and lowest quality of their kind

available. The bandsaw is as fancy as it got. I bought it second hand at

a car boot sale for £20 and thought I'd really wasted my money until I

got a new blade for it, but it still leaves a fairly wobbly and

off-square cut. The cover is off to show off the cheap construction. All

of the stuff I cut with it I could've cut with the jigsaw though.

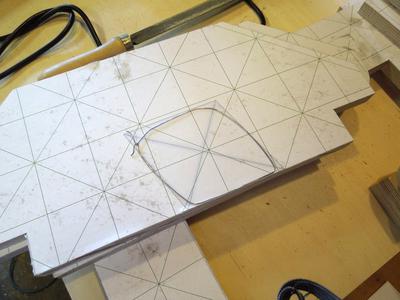

I stuck pretty close to how you made yours for the most part. Although I

secured the motor by drilling through the guard plate, and relying on a

tight fit (traced from solder wire, a trick I found on

Cosmas Bauer's

YouTube channel) in the back.

I stuck pretty close to how you made yours for the most part. Although I

secured the motor by drilling through the guard plate, and relying on a

tight fit (traced from solder wire, a trick I found on

Cosmas Bauer's

YouTube channel) in the back.

I also glued the extra pieces to the depth pivot when I found out my

16mm Forstner bit was cutting a bit oversized and making a loose fit. By

drilling the holes in the extra bits first, I could clamp them on in

such a way as to make for a snug enough fit with the steel bar.

I also glued the extra pieces to the depth pivot when I found out my

16mm Forstner bit was cutting a bit oversized and making a loose fit. By

drilling the holes in the extra bits first, I could clamp them on in

such a way as to make for a snug enough fit with the steel bar.

I flattened and squared up a piece of 2x4 for the fence with an old

trick you've probably seen before, using a router sled sliding on two

rails. I made securing the wood down more awkward than it needed to be

though, since I was trying to avoid drilling any unnecessary holes in the

sheet of birch plywood I was using as a flat reference. That plywood was

dang expensive.

I flattened and squared up a piece of 2x4 for the fence with an old

trick you've probably seen before, using a router sled sliding on two

rails. I made securing the wood down more awkward than it needed to be

though, since I was trying to avoid drilling any unnecessary holes in the

sheet of birch plywood I was using as a flat reference. That plywood was

dang expensive.

I simplified the fence rail a fair bit too. Since the bench the saw is

going on has support on all four sides, I didn't think I needed the

extra strength of a full rail. I also didn't feel confident my partially

finished table saw would cut accurately enough to make a decent one.

I simplified the fence rail a fair bit too. Since the bench the saw is

going on has support on all four sides, I didn't think I needed the

extra strength of a full rail. I also didn't feel confident my partially

finished table saw would cut accurately enough to make a decent one.

The saw still isn't quite finished though. I've got to get everything

better aligned, as well as figure out how to fix the wobble on the

arbour. I do own a small metal lathe so that gives me options.

The saw still isn't quite finished though. I've got to get everything

better aligned, as well as figure out how to fix the wobble on the

arbour. I do own a small metal lathe so that gives me options.

The reason I didn't use the metal lathe to make a fancier table saw in the first place is just that I've found it difficult to source powerful enough motors without spending a lot of money.

Thanks, Simon Heslop

Simon Heslop also has a YouTube channel, well worth checking out. I convinced him to make a short video about this saw as well. His other videos are much more elaborate, but Simon figured the construction of a homemade table saw was already well covered by my video series about my table saw.

More machines by Simon Heslop:

More homemade table saws:

Hector Acevedo's

homemade table saw

Hector Acevedo's

homemade table saw Lucas Contreras's

homemade table saw

Lucas Contreras's

homemade table saw Dad's

homemade

Dad's

homemadetable saw

Back to my Woodworking website.

Oscillating spindle sander

Oscillating spindle sander Drum sander

Drum sander Homemade table saw

Homemade table saw