Mortising on the drill press

A conventional method for mortising with a drill press is to use one of these hollow

chisel mortiser drill press adapters.

A conventional method for mortising with a drill press is to use one of these hollow

chisel mortiser drill press adapters.

The problem with these adapters is that they extend the quill of the drill press way down. The quill on most drill presses has a bit of play to begin with, and to extend it this far makes for a less than rigid arrangement.

The bracket that I'm showing here is actually no longer usable - it's what's left of one of these adapters after I experimented with building a hollow chisel mortiser

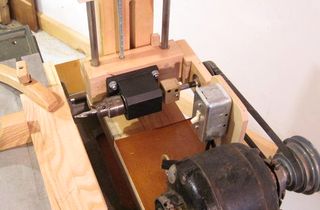

I'm going to use a spiral up-cut router bit (an Onsrud router bit, to be exact) as a very short drill

to hog out the material. I mount this bit as far into the chuck as I can so that it barely extends

out far enough to cut the mortises.

I'm going to use a spiral up-cut router bit (an Onsrud router bit, to be exact) as a very short drill

to hog out the material. I mount this bit as far into the chuck as I can so that it barely extends

out far enough to cut the mortises.

The key is to very rigidly hold the wood right up to the drill. My workpiece is clamped in a

drill press vise. The vise in turn is clamped to the table, and the table is locked in place.

The key is to very rigidly hold the wood right up to the drill. My workpiece is clamped in a

drill press vise. The vise in turn is clamped to the table, and the table is locked in place.

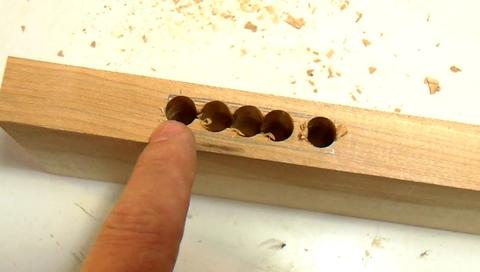

Next I drill out a series of holes to hog out most of the material. I have enough rigidity

in this setup so that if the drill breaks through to the adjoining hole, it doesn't get

pulled to the side.

Next I drill out a series of holes to hog out most of the material. I have enough rigidity

in this setup so that if the drill breaks through to the adjoining hole, it doesn't get

pulled to the side.

I clamp and un-clamp the work piece for each hole.

Next I drill another series of holes half way between the previous set of holes. I now have

most of the material hogged out.

Next I drill another series of holes half way between the previous set of holes. I now have

most of the material hogged out.

With just ridges remaining between the overlapping holes, it's easy to get in there and smooth

out the sides of the mortise.

With just ridges remaining between the overlapping holes, it's easy to get in there and smooth

out the sides of the mortise.

This method is not the fastest, and it's not the cleanest. Though I think the result is quite comparable to what you would produce with a hollow chisel mortiser. But unlike hollow chisel mortiser mortises, the bottom of this mortise is square and flat.

Short, flat and stubby drills work best for this method. From left to right, a 3/8" Onsrud bit,

a 1/2" endmill, and a 1/2" Forstner bit. All these can be used.

Short, flat and stubby drills work best for this method. From left to right, a 3/8" Onsrud bit,

a 1/2" endmill, and a 1/2" Forstner bit. All these can be used.

On the right, a 3/8" brad point bit, and a regular 3/8" drill bit. The drills on the right are not suitable, especially the furthest to the right. The drills are too long and are likely to flex or cause flexion in the drill press. The pointy front of the last drill is especially prone to following previously made cuts.

See also:

A square drill for round holes

A square drill for round holes Cheap fortsner bits: Low quality but they drill ok (video only)

Cheap fortsner bits: Low quality but they drill ok (video only)More about Mortise and tenon joints More Shop Tricks

Homemade horizontal

Homemade horizontal Hollow chisel mortiser

Hollow chisel mortiser Simple mortising jig

Simple mortising jig Chain mortiser

Chain mortiser Home made slot

Home made slot