Angus Ross-Thomson's pantograph

Angus writes:

Angus writes:Hello Matthias

Your recent article on wooden rings has finally persuaded me that I might have something useful to contribute to the wonderful world of Woodgears.ca. Some of your readers' projects are so elegant and well made that I hesitated to draw attention to my ham fisted efforts. However, I have produced a circle fixture for my pantograph jig which may be of interest.

I always have enjoyed making stuff in a small way, mostly concentrating on electronics, PIC chips, software and low level mechanical engineering. My proudest products were a portable aircraft instrumentation system for flight testing (I was a test pilot in the Royal Air Force back when I had to work for a living) and a radar warning receiver for use on boats to warn of the approach of ships.

In 2005, my wife and I set off on an nine year circumnavigation on our sailing yacht which was a great experience but I really missed my small workshop and the facilities for making the dozens of widgets one needs around a live-aboard boat. However, during our time away I came across your website which was a complete inspiration and opened up a whole new way of approaching projects. I whiled away many a night watch under the stars imagining the creations I would make on my return, and watching your videos whenever I could find an internet cafe that could manage more than 5kbps (it was often a slow and painful process).

We returned to the UK last year and having got the house habitable, I placed an order on your website for five plans, including the screw advance box joint jig, the pantorouter and the pantograph. I completed the BJJ first, then the pantorouter and finally the pantograph. I have made a widget to help projects constructed with the pantograph, so I shall describe that first, and if you think it may be of interest and you have the time, I shall describe my experiences in constructing and using the BJJ and pantorouter in another email.

|

Having already made a BJJ and pantorouter, the pantograph was fairly

straightforward. As maple is almost an exotic species around here, I

used oak for the hardwood along with the usual birch ply.

I was soon knocking out plaques and signs that were scattered around the house and garden (you may recognise the style of handle on the shed door.) In fact one of my neighbours asked me to make an oak memorial plaque for her parents' graves, my first commission. |

|

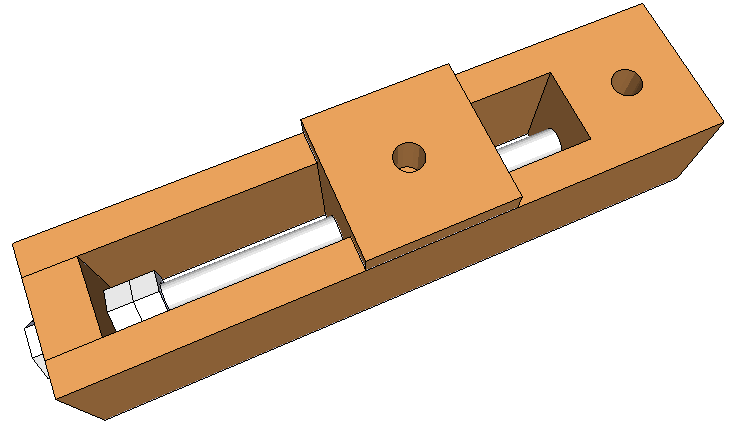

To the point of my email. I really liked the embedded knobs that you

used on your recessed drawer pulls

and wanted to use them on a bathroom

cabinet I have in mind. However I had trouble using your method of

inserting the follower in holes in a rotating wood strip. Fine

adjustments were tricky and I could not get the hang of sliding a

dovetail bit in at an angle. So I produced the adjustable fixture shown

in the picture and SketchUp diagram which may also be relevant

for your rings.

|

The fixture rotates on a short stainless steel pin located in the piece

of chipboard and the pantograph follower rotates in the hole in the

moveable block. There is a pencil scale on one side of the slot, and to

help repeatability, I put a piece of masking tape on the other with the

critical positions marked. The adjustments are made by turning the M6

bolt with a socket.

The fixture rotates on a short stainless steel pin located in the piece

of chipboard and the pantograph follower rotates in the hole in the

moveable block. There is a pencil scale on one side of the slot, and to

help repeatability, I put a piece of masking tape on the other with the

critical positions marked. The adjustments are made by turning the M6

bolt with a socket.

I produce the initial circular groove with a straight router bit, I then use a round nosed bit to round the bottom of the groove, then wind the cutter inwards to undercut the knob. Finally, I use a roundover bit for the top edge of the knob and the outer rim of the hole. I can now produce the knobs reasonably consistently and accurately in about 10 minutes including bit changes.

Download radius widget SketchUp model

Download radius widget SketchUp model

Thanks for your inspiration and guidance.

All the best.

Angus Ross-Thomson

UK.

See also:

Recessed drawer pulls

Recessed drawer pulls Elyasaf's pantograph

Elyasaf's pantograph John Baker's

John Baker's Pascal Zingg's

Pascal Zingg's Ken Coulter's pantograph

Ken Coulter's pantograph More about the pantograph

More about the pantograph