Unboxing the all-metal pantorouter (2013)

I don't often get "freebies" sent to me, which I'm quite ok with, because I'd always

wonder how much coverage I'd owe the "free" thing.

I don't often get "freebies" sent to me, which I'm quite ok with, because I'd always

wonder how much coverage I'd owe the "free" thing.

But this "freebie" is different. Kuldeep Singh (an Indian guy living in Japan) has been building and selling pre-built all metal pantorouter machines. He offered to send me a royalty for the machines, but I told him to set the money aside and send me a machine once the royalties add up to the price of a machine.

So (in 2013) the numbers finally added up to a machine, and Kuldeep sent me one.

Kuldeep has been experimenting with building pantorouter machines from all

metal for some time. I first posted about his machine

back in February 2012 (at left, his first machine)

Kuldeep has been experimenting with building pantorouter machines from all

metal for some time. I first posted about his machine

back in February 2012 (at left, his first machine)

I made lengthy video of most of the unpacking and assembly.

The packaging was perhaps a bit messy, but effective.

Then again, when I sold

marble adders or Jenga pistols,

my packaging was not that neat either.

I made lengthy video of most of the unpacking and assembly.

The packaging was perhaps a bit messy, but effective.

Then again, when I sold

marble adders or Jenga pistols,

my packaging was not that neat either.

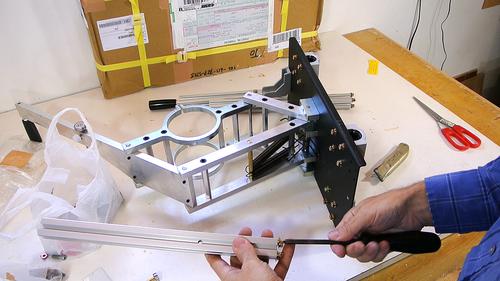

The main pantograph was pre-assembled, which was nice. I think that mechanism

would be quite prone to getting assembled incorrectly.

The main pantograph was pre-assembled, which was nice. I think that mechanism

would be quite prone to getting assembled incorrectly.

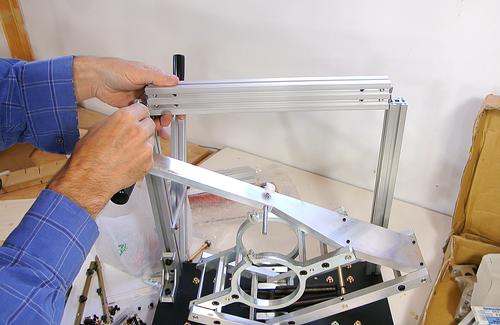

Assembling the template holder frame, which mounts behind the pantograph.

Assembling the template holder frame, which mounts behind the pantograph.

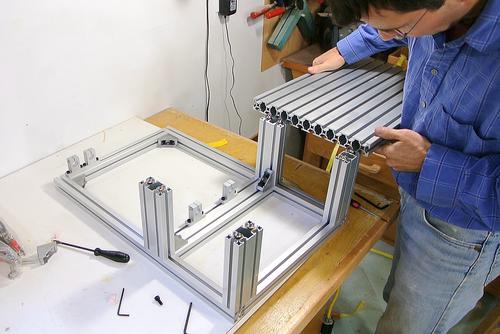

The whole frame is made of these industrial T-slot rails. I have seen this type

of rail used in factories to build jigs. It's quite a neat system, and

very precise.

The whole frame is made of these industrial T-slot rails. I have seen this type

of rail used in factories to build jigs. It's quite a neat system, and

very precise.

First test of the machine. I was afraid the pantograph mechanism might feel

a little floppy, but it's actually quite stiff. The whole machine feels very

precise.

First test of the machine. I was afraid the pantograph mechanism might feel

a little floppy, but it's actually quite stiff. The whole machine feels very

precise.

The table, with the many slots on it is also very nice for jigging things up on. Although for very thick (5 cm or more) work pieces, the toggle clamps don't open far enough. So I just put bar clamps over the edges of the table for larger pieces.

I should add, the toggle clamps are not included by default (an extra $65 option)

The design of Kuldeep's metal pantorouter machine has evolved over time.

On testing the machine, I had some suggestions as well. One was to increase the

plunge depth, which I was able to do by assembling the machine slightly differently, with

the table further from the router. When making large mortises and tenon joints, you need

a lot of plunge depth because the mortises are cut on the table, but the tenons are cut

overhanging the table. Then, to be able to back away from the tenon, even more depth

is needed.

The design of Kuldeep's metal pantorouter machine has evolved over time.

On testing the machine, I had some suggestions as well. One was to increase the

plunge depth, which I was able to do by assembling the machine slightly differently, with

the table further from the router. When making large mortises and tenon joints, you need

a lot of plunge depth because the mortises are cut on the table, but the tenons are cut

overhanging the table. Then, to be able to back away from the tenon, even more depth

is needed.

Having put the machine through its paces, I'm happy to say that I like it. One of the things that I figured could use improvement was instructions on how to put the machine together, so I spent the time putting together a set of assembly instructions. For me, assembly was a puzzle I quite enjoyed. Much better than a jigsaw puzzle!

Kuldeep has also designed an improved set of depth stops, which I made a short video about

And at this point, I feel like I have contributed to this particular machine, so I don't feel guilty about earning a little bit of money off it.

The machine does cost more than cheap tools from China. But when you compare it to over $1100 for a Leigh FMT Pro, and how limited that machine is, I think Kuldeep's pantorouter is a bargain! Especially considering that he puts these together one at a time, without fancy automated machinery or cheap Chinese labour.

| A video of Kuldeep demonstrating the machine, with a dovetail template that he also sells. Also shwon, a 65 mm diameter router mount for smaller routers. |

Update: Mac Sheldon has bought the pantorouter business from Kuldeep. If you would like to buy one of these machines, see here

|

Frank Howarth has made an excellent video of using the pantoroute to make

inlays for a bowl.

He also includes a cool animation of assembling the pantorouter, which is at 3:54 seconds into the video. |

See also:

Buy an all-metal

Buy an all-metalpantorouter (old page)

Assembly instructions (2015 version)

Assembly instructions (2015 version)Back to my woodworking website

More about the

More about the Kuldeep's pantorouter production (2013)

Kuldeep's pantorouter production (2013) Comparing with the

Comparing with the Setting up dovetails with

Setting up dovetails with