I was lucky that the stain didn't penetrate too far into the wood, and scraping the

surface took care of most of it. After removing the varnish, I sanded

the surface with my belt sander.

I was lucky that the stain didn't penetrate too far into the wood, and scraping the

surface took care of most of it. After removing the varnish, I sanded

the surface with my belt sander.

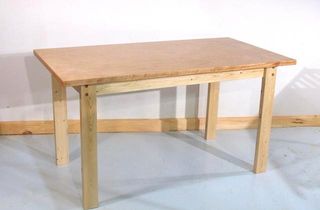

For a simple table that I built I reused the slab of

wood that originally was the top of a 1970s wooden government desk.

The slab is incredibly heavy, with a nice hardwood veneer on the top and bottom.

The core of the slab is just particle board though.

For a simple table that I built I reused the slab of

wood that originally was the top of a 1970s wooden government desk.

The slab is incredibly heavy, with a nice hardwood veneer on the top and bottom.

The core of the slab is just particle board though.

I started by scraping the varnish off with a 1.25" wide chisel. This takes lots of force and elbow grease. I'm holding the chisel vertically against the surface, and pushing down hard on it as I drag it across. The chisel needs to be quite sharp for it to take off the varnish, and it dulls quickly. It's good for a patch about twice the size I'm doing in the photo before it needs a light resharpening to continue.

I prefer scraping the varnish to sanding it. Varnish tends to gum up sanding belts. I'm don't like the idea of turning whatever is in the varnish into fine dust in my work area either. So elbow grease is the way to go.

I was lucky that the stain didn't penetrate too far into the wood, and scraping the

surface took care of most of it. After removing the varnish, I sanded

the surface with my belt sander.

I was lucky that the stain didn't penetrate too far into the wood, and scraping the

surface took care of most of it. After removing the varnish, I sanded

the surface with my belt sander.

Like when refinishing floors, its important to keep the belt sander moving across the surface, so it doesn't dig in at any particular spot. Though using this belt sander trick cuts down on this quite a bit.

The next step is to go over it with a cabinet scraper. I have a page on

using a cabinet scraper.

The next step is to go over it with a cabinet scraper. I have a page on

using a cabinet scraper.

I use the cabinet scraper to get the surface nice and smooth. It doesn't take away material as fast as the belt sander, but its a lot quicker than using fine sand paper.

The next step is varnishing. I used water based Varathane floor varnish. It costs a bit more

than the regular furniture varnish, but it comes out smoother and harder.

The next step is varnishing. I used water based Varathane floor varnish. It costs a bit more

than the regular furniture varnish, but it comes out smoother and harder.

To do a table top, you need a minimum of three coats, with a light sanding with 240 or finer sand paper in between. Though this slab was starting to become glossy after just two coats. Probably because remainders of the old varnish in the wood acted as a sealing coat.

I like to put a nice and thick final coat on the top of the table. The manufacturer's instructions say to use thin coats. Probably because if you put too much on, it tends to run. But with a horizontal table top, this is not much of an issue.

I ended using this table top for building this simple table

To illustrate how much varnish I have used at times, see the image at left. This was

the final coat of varnish on this table. I used

oil based, as opposed to the water based Varathane on this table. This gives more

time to work with the varnish, dries a bit smoother, and is better against moisture.

To illustrate how much varnish I have used at times, see the image at left. This was

the final coat of varnish on this table. I used

oil based, as opposed to the water based Varathane on this table. This gives more

time to work with the varnish, dries a bit smoother, and is better against moisture.

I actually ended up pouring the varnish on and then spreading it with a brush.

I actually ended up pouring the varnish on and then spreading it with a brush.

At right, final coat on a drawer front for my under bed drawers, with water based varnish. Water based varnish doesn't give this luxury of time, but the oil based varnish takes a day to dry between coats, and it's smelly. The water based varnish is much more practical to use in the winter.

How to build a simple table (2008)

How to build a simple table (2008) Round dining table (2007, 1996)

Round dining table (2007, 1996) Wood tiled table top (2007)

Wood tiled table top (2007) More about building

More about building Refacing drawers (2008)

Refacing drawers (2008) A simple varnish (2015)

A simple varnish (2015) Varnishing tips (video, 2021)

Varnishing tips (video, 2021)