Elyasaf's tenon jig

Elyasaf writes:

Elyasaf writes:Dear Matthias,

I have completed the quick set tenon jig. As usual, your machines are incredibly smart yet simple, but I guess you are probably tired of compliments by now, so I'll get to the point.

The jig was really fun and challenging to build. The linkage mechanism is very interesting and it is relatively easy to build. Like one of your readers stated before, my wife doesn't really get the point of producing more and more machines in my workshop, while she is still looking for the outcomes, and for the income that should come along :)

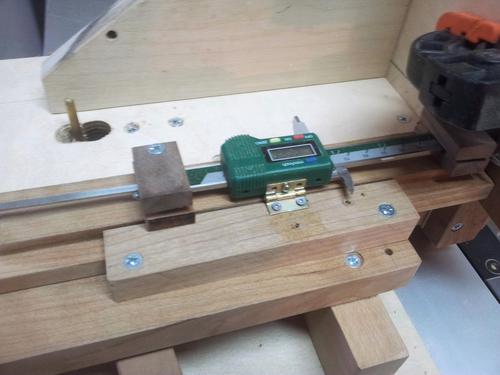

Since I didn't finish the slot mortising machine yet (still working on

it, though maybe I will build the pantorouter instead), I didn't check

its accuracy with mortise and tenons, but I did try it with half lap

joints. It was really intriguing to see that the jig 'challenges' the

digital calliper accuracy. In other words - the accuracy of the jig is

limited by the calliper tolerance (suppose to be +/-0.02mm, but apparently

it seems less accurate than that).

Since I didn't finish the slot mortising machine yet (still working on

it, though maybe I will build the pantorouter instead), I didn't check

its accuracy with mortise and tenons, but I did try it with half lap

joints. It was really intriguing to see that the jig 'challenges' the

digital calliper accuracy. In other words - the accuracy of the jig is

limited by the calliper tolerance (suppose to be +/-0.02mm, but apparently

it seems less accurate than that).

Some points I would like to highlight:

1. Since I'm using a European style table saw, with a sliding table

to the left of the blade, I had to mirror the jig and all components so it

would hold the wood piece and bring it to the blade from the left side.

I was considering several options on how exactly it should be done. I

have ended up making all the parts exactly as shown in plans (without

the countersinks), and turning each part upside down before installing them

in a mirrored manner. It worked, but it was somewhat confusing. I made

some errors because of that. From time to time I've turned over the

plans and looked at them over a window (against sunlight) so I can see

how it is suppose to look. The only downside of this is that on the

jig I have to read the calliper upside down. But I don't have any

trouble reading it like that.

1. Since I'm using a European style table saw, with a sliding table

to the left of the blade, I had to mirror the jig and all components so it

would hold the wood piece and bring it to the blade from the left side.

I was considering several options on how exactly it should be done. I

have ended up making all the parts exactly as shown in plans (without

the countersinks), and turning each part upside down before installing them

in a mirrored manner. It worked, but it was somewhat confusing. I made

some errors because of that. From time to time I've turned over the

plans and looked at them over a window (against sunlight) so I can see

how it is suppose to look. The only downside of this is that on the

jig I have to read the calliper upside down. But I don't have any

trouble reading it like that.

2. Using the sliding table means I don't need to slide the jig itself

on a surface. Instead, I clamp it firmly to the sliding table. This is done

by making a wooden bar which fits into the sliding table T slot, and

adding a knob that attaches to a threaded metal T nut. After sliding the

table all the way to the cross cut fence, I tighten the knob - and I'm

ready to go. I am now using the same method on

my screw advance box joint jig,

instead of clamping it straight to the cross-cut fence (like I did before).

2. Using the sliding table means I don't need to slide the jig itself

on a surface. Instead, I clamp it firmly to the sliding table. This is done

by making a wooden bar which fits into the sliding table T slot, and

adding a knob that attaches to a threaded metal T nut. After sliding the

table all the way to the cross cut fence, I tighten the knob - and I'm

ready to go. I am now using the same method on

my screw advance box joint jig,

instead of clamping it straight to the cross-cut fence (like I did before).

3. Clamping the calliper - I figured that using the tiny thread of the

tightening screw would be wiser than dealing with rubber bands. It keeps

it 100% clamped with no play or gaps.

3. Clamping the calliper - I figured that using the tiny thread of the

tightening screw would be wiser than dealing with rubber bands. It keeps

it 100% clamped with no play or gaps.

4. While building my slot mortising machine, I had a frustrating

experience trying to align two separate bushings to accept one rod.

Inspired by one of your readers, I found this self aligning

bearing, which are made exactly for situations like this. They don't

cost so much as well. Actually, they were cheaper than the bronze

bushings. I wouldn't recommend ordering simple bushing, not

only the trouble you need to go through to make it work (as you describe

in your plans), also in my opinion, mechanically speaking it doesn't

seem correct.

4. While building my slot mortising machine, I had a frustrating

experience trying to align two separate bushings to accept one rod.

Inspired by one of your readers, I found this self aligning

bearing, which are made exactly for situations like this. They don't

cost so much as well. Actually, they were cheaper than the bronze

bushings. I wouldn't recommend ordering simple bushing, not

only the trouble you need to go through to make it work (as you describe

in your plans), also in my opinion, mechanically speaking it doesn't

seem correct.

Above: Self aligning bushings installed. |

|

Best Regards,

Elyasaf Shweka.

Israel

See also:

Yiyong Leng's tenon jig

Yiyong Leng's tenon jigMore on Mortise and tenon joints

To my woodworking website

Quick-set tenon jig

Quick-set tenon jig Elyasaf's screw advance box joint jig

Elyasaf's screw advance box joint jig Dan Chernoff's quick-set tenon jig

Dan Chernoff's quick-set tenon jig Harlan Opie's quick-set tenon jig

Harlan Opie's quick-set tenon jig Slot mortiser

Slot mortiser Mortise and tenon joint accuracy

Mortise and tenon joint accuracy Delta tenon jig review

Delta tenon jig review