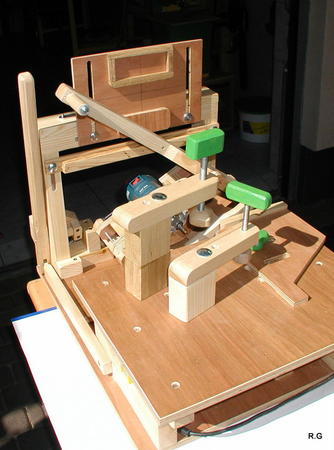

Ryszard's pantorouter

Ryszard writes:

Hello Matthias,

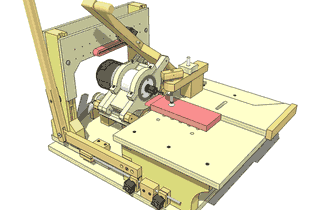

For the last 10 days I have been working on building the Pantorouter. Your device is designed very precisely. Its construction is well thought out and thoroughly tested.

I think that you have spent many hours of work on the device to look as it does in the plans. Everything has got its justification. Actually, although I am an engineer, I did not have to improve anything. I made everything exactly following the plans and the videos on your website. It turned out perfectly. Your device is a gem – working on it was a real pleasure.

I used a GKF 600 router (I think bought it under the name COLT) However I had to make some changes: instead of 19mm I used 18mm plywood since this was the only available; instead of maple I used pine and ash (the maple is not available in my area and I had some ash left). I did not buy knobs, instead I hand-made them - I could not find them for sale. I used the ball tracks from a computer keyboard drawer as tracks for the mobile table. They are solid, steel. I used additional balls out of the ball track bought on sale (now I need to use some other solution for the keyboard).

All my machines and accompanying devices for the table saw and the router that I have been using so far worked perfectly while making the Pantorouter (you published most of them on the 19th March on your site). I could not stop working, I was so involved.

You will probably notice that the electrical installation is more developed: I used a relay safety switch and a self-assembled electronic speed controller. The adjuster uses triac and a U2008B chip (purchased for DYI enthusiasts’ self-assembly) designed for the brush motors. The speed controller enables speed regulation from 5% to 95%. It also has a soft-start circuit. It uses an aluminium heat sink for cooling the triac. It can control motors up to 2.5kW. It's mounted up under the table as you can see on the pictures.

Since I don’t like tangling cables, I added a cable holder on the side for coiling the cable, and a socket for the router and the light.

I'm making some templates now, your instructions are invaluable here as well, very helpful and time efficient. I will be using an 8 mm spiral cutter and a corresponding 16 mm bearing on the copying lever.

Best Regards,

Ryszard

|

|

Ryszard later wrote:

Today I finished the pantorouter mobile stand. See pictures.

Last week I built a mobile table saw stand.

In both cases I used ideas from

your designs.

Ryszard

P.S

Congratulations on the new project - the copy carving router machine

See also:

Back to woodgears.ca

Spindle sander

Spindle sander 14" bandsaw

14" bandsaw

Tilting router lift

Tilting router lift Homemade jointer

Homemade jointer Homemade lathe

Homemade lathe Chaise lounge build

Chaise lounge build The pantorouter

The pantorouter Reader built

Reader built Pantorouter plans

Pantorouter plans More reader projects

More reader projects